Fastening device for heat shield

A fastening device and fastening technology, which is applied in the direction of aircraft power devices, aircraft power device components, thin plate connections, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

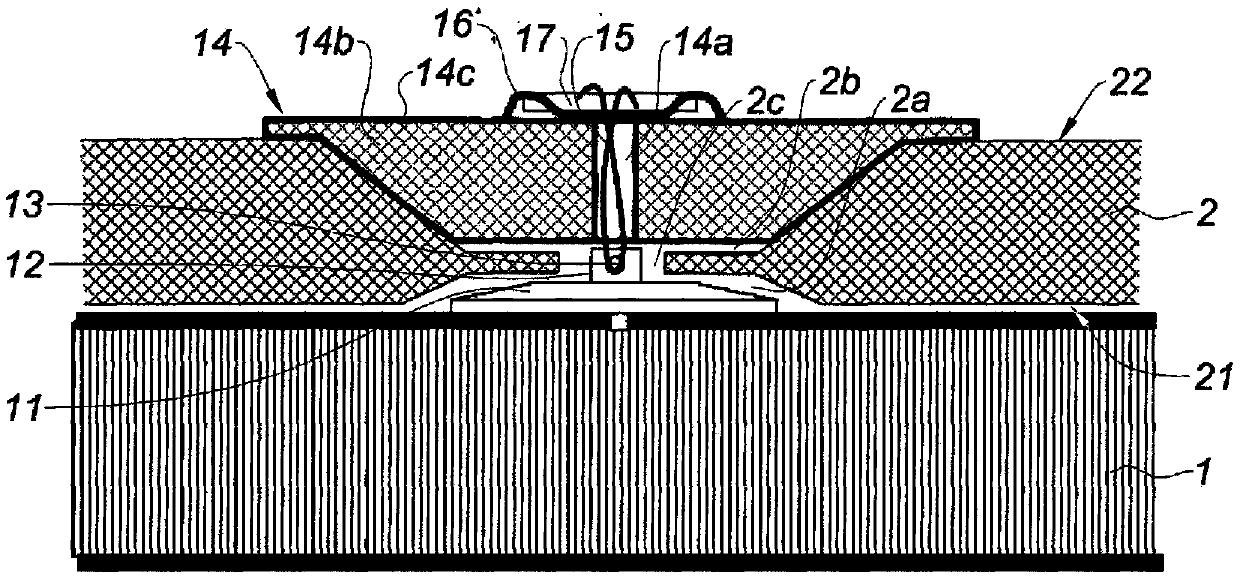

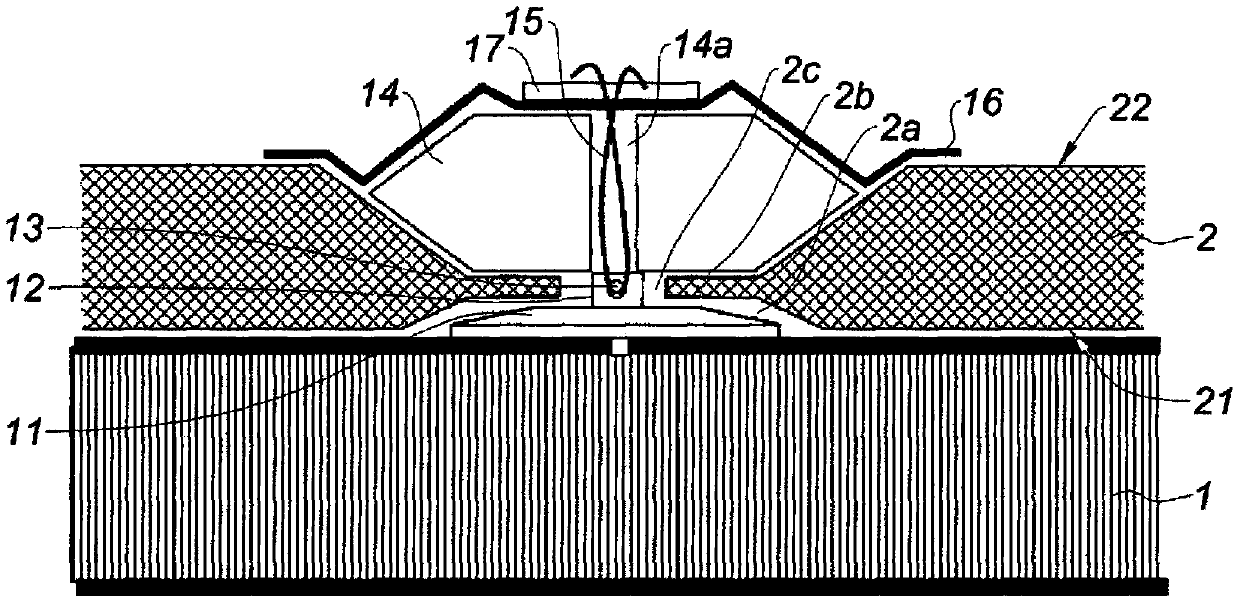

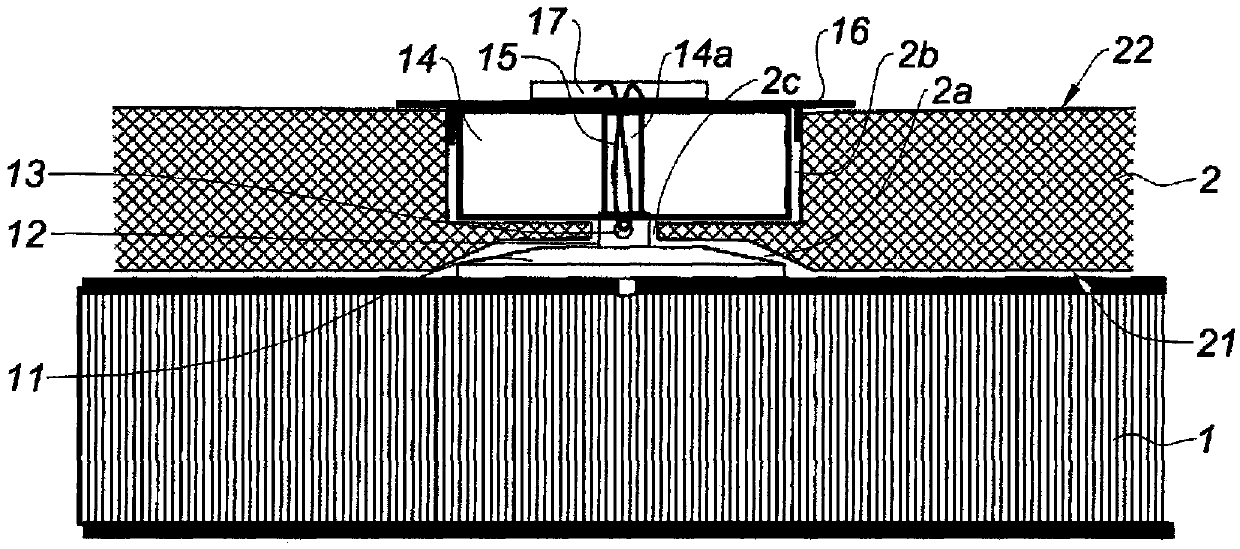

[0038] figure 1 Is a sectional view of a part of the Internal Fixing Structure 1 (IFS) of a turbojet engine nacelle, a heat shield 2 is fastened to this illustrated part by means of a plurality of fastening means. Pad 2 comprises a surface in contact with structure 1 (referred to as inner surface 21 ) and an opposite surface (referred to as outer surface 22 ).

[0039] According to the invention, at least one means for fastening the pad 2 to the structure 1 comprises a fastening base 11 . The base is fastened to the fixing structure 1 , for example by gluing, and is equipped with hooking structures 12 . In the example, the hooking structure 12 is in the form of an eye bolt 13 protruding in a direction substantially perpendicular to the surface of the structure 1 to which the base 11 is attached.

[0040] The anti-heat mat 2 covers the base 11 in an opening or cavity 2 a with a shape formed over the thickness of the mat 2 that is substantially complementary to the base 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com