Amphibian bait casting machine system

An amphibious, bait-feeding machine technology, which is applied in applications, fish farming, climate change adaptation, etc., can solve the problems of unfavorable deep-water fish farming, etc., and achieve the effect of simple structure, strong practicability, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

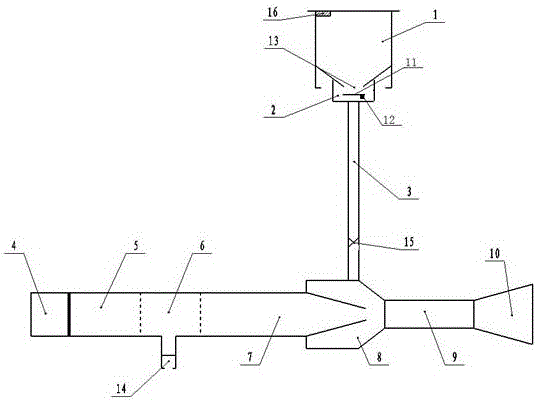

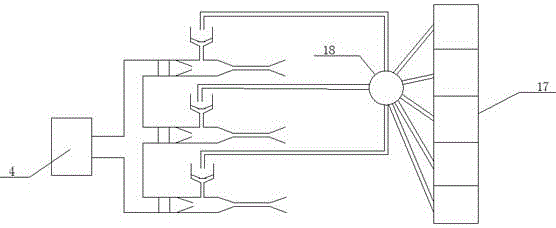

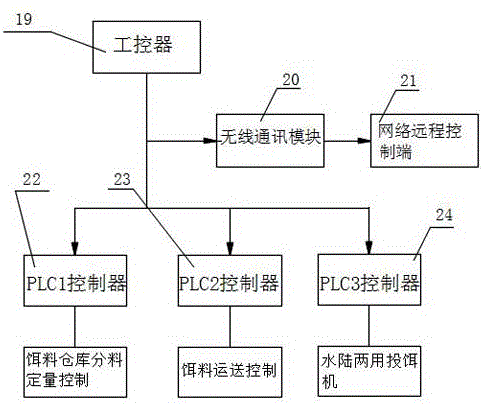

[0031] An amphibious bait thrower system, such as figure 1 As shown, it includes a feeding mechanism, a high-pressure fluid generator 4, a high-pressure fluid spray chamber 7, a negative pressure chamber 8, a mixing chamber 9 and a mixture releasing chamber 10. The feeding mechanism is located above the negative pressure chamber 8, and the feeding mechanism passes through a guide The material pipe 3 communicates with the negative pressure chamber 8, the high-pressure fluid spray chamber 7 is located on one side of the negative pressure chamber 8, the mixing chamber 9 is located on the other side of the negative pressure chamber 8, and the high-pressure fluid generator 4 flows to the high-pressure chamber through a guide pipe 5. The fluid spray chamber 7 transports high-pressure fluid, the nozzle of the high-pressure fluid spray chamber 7 is inserted into the negative pressure chamber 8, the outlet of the negative pressure chamber 8 communicates with the inlet of the mixing cham...

Embodiment 2

[0034] This embodiment is a further improvement on the above-mentioned embodiment, as figure 1 As shown, in this embodiment, the feeding mechanism includes a bait bin 1 and a distributing bin 2 arranged below the bait bin 1, the outlet of the distributing bin 2 communicates with the feed pipe 3, and the bait bin 1 is mainly used for storing For bait, a partition 11 is arranged between the bait bin 1 and the distribution bin 2, and a vibrator 12 is arranged on the partition 11, and the interval time and frequency of the vibrator 12 are controlled by the controller 16 to realize the control of the amount of bait feeding. The controller 16 can be installed in the bait bin 1 or indoors. The controller 16 is also used to control the operation and shutdown of the high-pressure fluid generator 4 in addition to controlling the amount of bait thrown.

Embodiment 3

[0036] This embodiment is a further improvement on the above-mentioned embodiment, as figure 1As shown, in this embodiment, a photosensitive sensor 13 is provided at the discharge port of the bait bin 1, and the photosensitive sensor 13 can adopt models HL304HP and HL504HP to judge whether the bait is used up. 13 sends delay stop signal to controller 16, and controller 16 will control high-pressure fluid generator 4 shutdown after a few minutes, and the staff can select to continue to add bait to bait storehouse 1 or close the present invention and finish feeding according to actual needs. At the moment of shutdown, the negative pressure in the negative pressure chamber 8 and the feed pipe 3 all changes from negative pressure to positive pressure, which is balanced with the water pressure. The deeper the water, the greater the pressure difference between the negative pressure and the positive pressure. The purpose of the delayed shutdown is to utilize the suction of the negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com