Electric stir-fryer

A kind of frying machine and electric technology, which is applied to cooking utensil lids, cooking utensils, household utensils, etc., can solve the problems of bulkiness and complexity, lack of cooking fun, inconvenient daily cleaning and maintenance of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

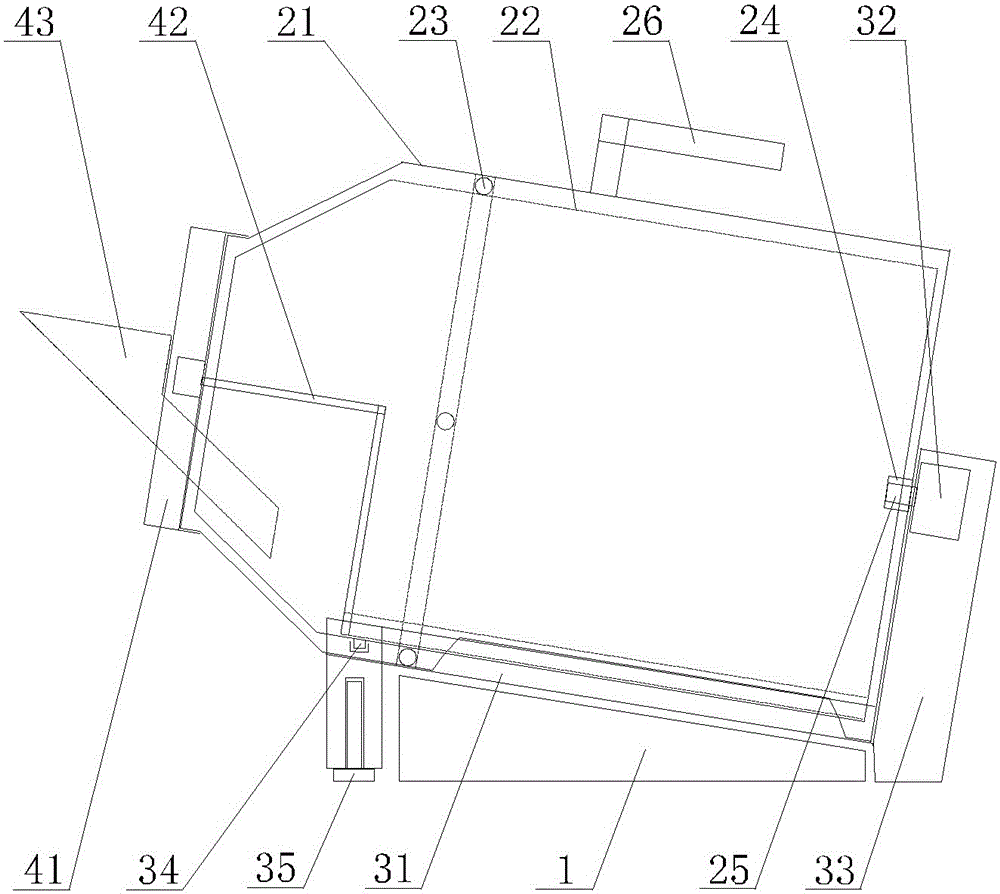

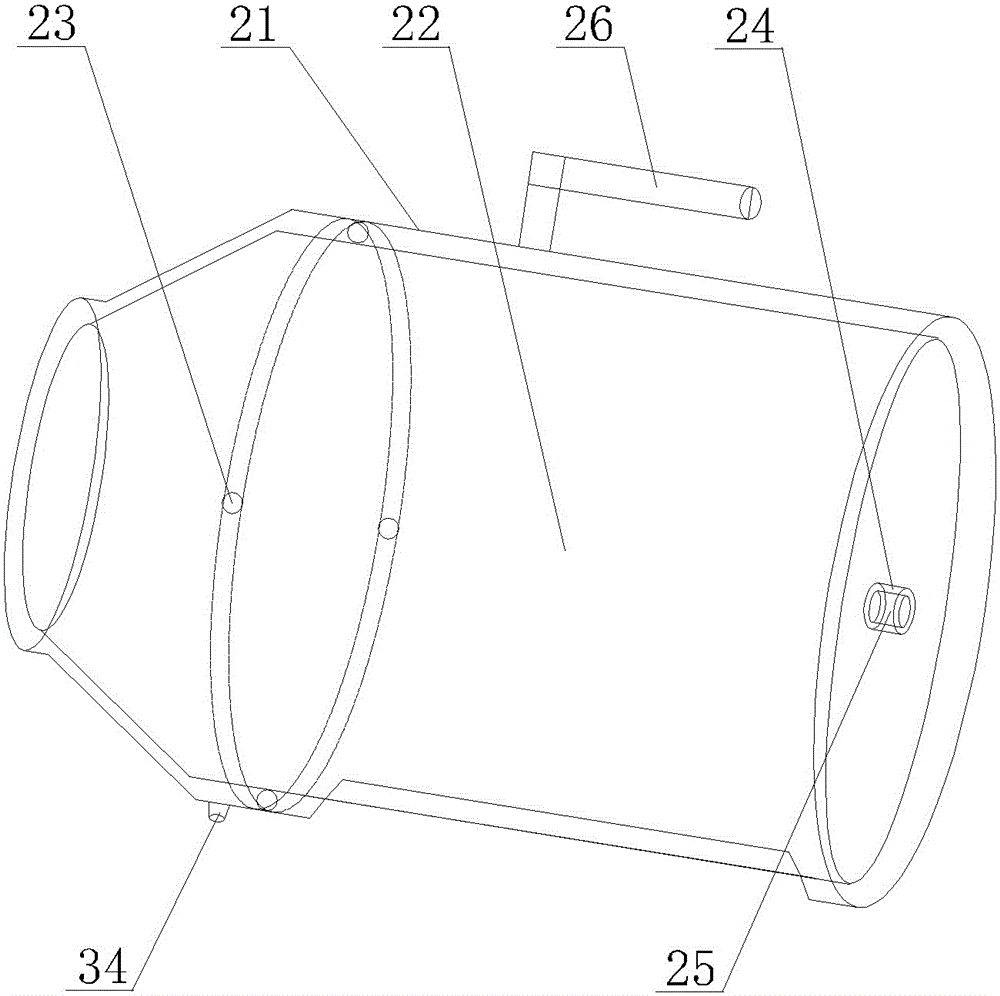

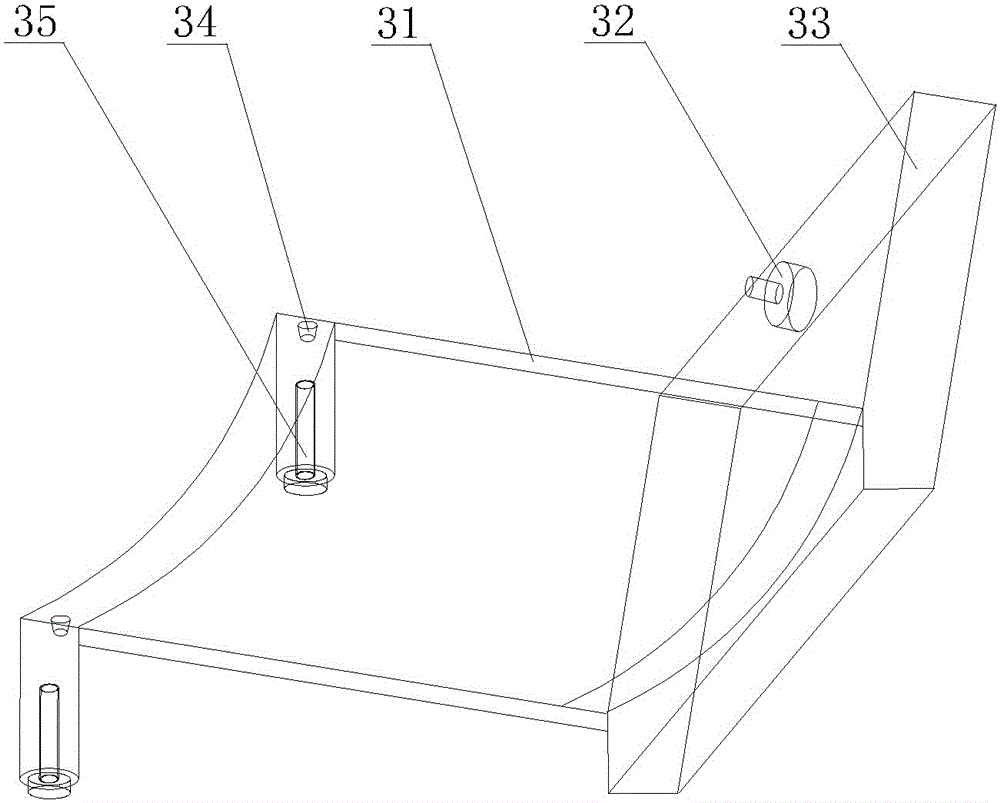

[0030] As a specific implementation example of the electric cooking machine of the present invention, as figure 1 , 2 , 3, 4, and 5, the structure of the electric cooking machine includes a pot body ( figure 2 ), base ( image 3 ), pot lid ( Figure 4 ), the four modules of induction cooker 1, the four modules are detachable for combined connection and use, the pot body ( figure 2 ) consists of a pot body shell 21, a pot inner tank 22, a front roller 23 of the inner tank, a rear roller 24 of the inner tank, and a connector 25, and the base ( image 3 ) is made up of hollow support 31, driving mechanism 32 and control circuit 33, base ( image 3 ) can be erected on various heat sources as the pot body ( figure 2 ) provides positioning support, the base ( image 3 ) on the drive mechanism 32 and the connector 25 at the bottom of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com