Patents

Literature

44results about How to "Achieve stir fry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic cooker

InactiveCN106618150AImplement automatic additionThe amount of seasoning added is controllableCooking-vessel lids/coversAutomatic controlEngineering

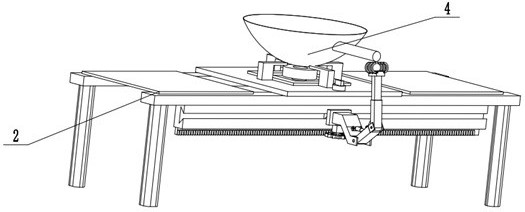

The invention relates to an automatic cooker which comprises a cooking bench, a conveyor belt, multiple pots, a hopper and pot covers. The two sides of the conveyor belt are provided with side plates; openings are formed in the portions, corresponding to the pots, of the side plates, and side wing grooves are formed in the openings; the lower ends of the side wing grooves are connected to the edges of pot openings of the pots in an abutting mode; a push plate and a first electric push rod for pushing the push plate towards the corresponding opening are arranged on the portion, corresponding to each opening, of the corresponding side plate, and stirring shovels are arranged in the centers of the pot covers. The automatic cooker has the advantages that automatic cooking can be achieved, multiple dishes can be independently cooked simultaneously, and not only can the cooking efficiency be improved, but also the single-pot single-dish delicious taste can be guaranteed; the whole process is automated, operation is easy and practical, both the adding quantity and the adding time of seasonings can be automatically controlled through programs, and the taste can be consistent.

Owner:吴佳涵

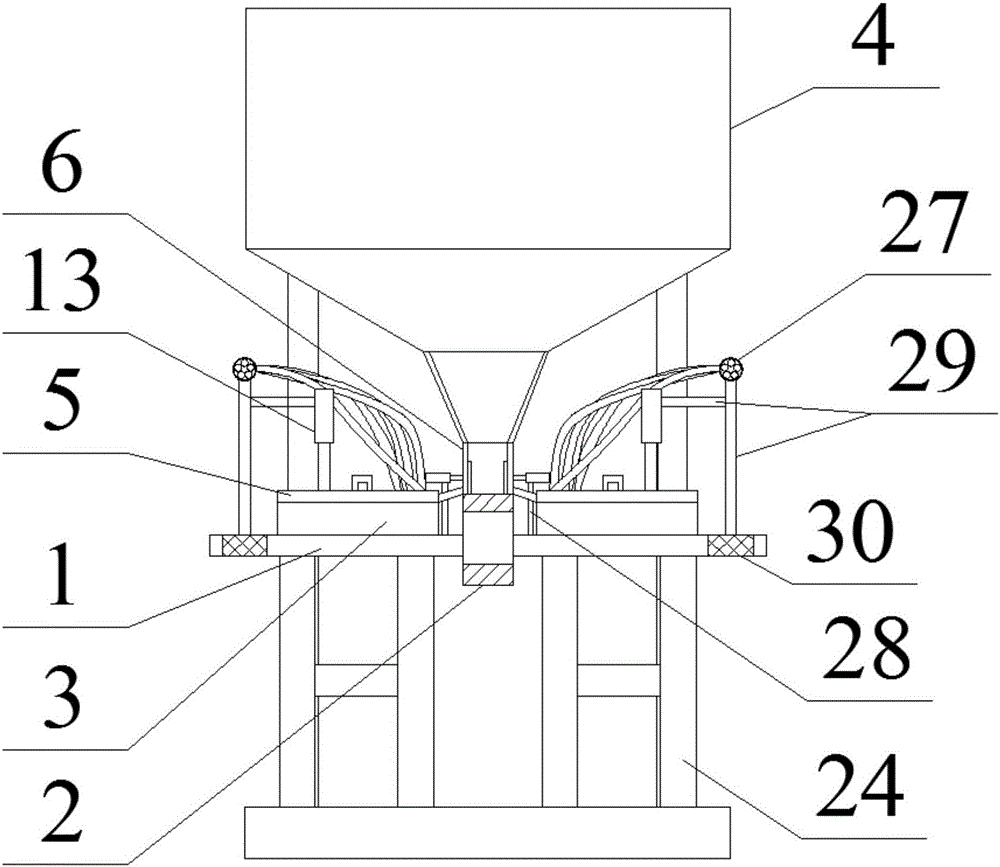

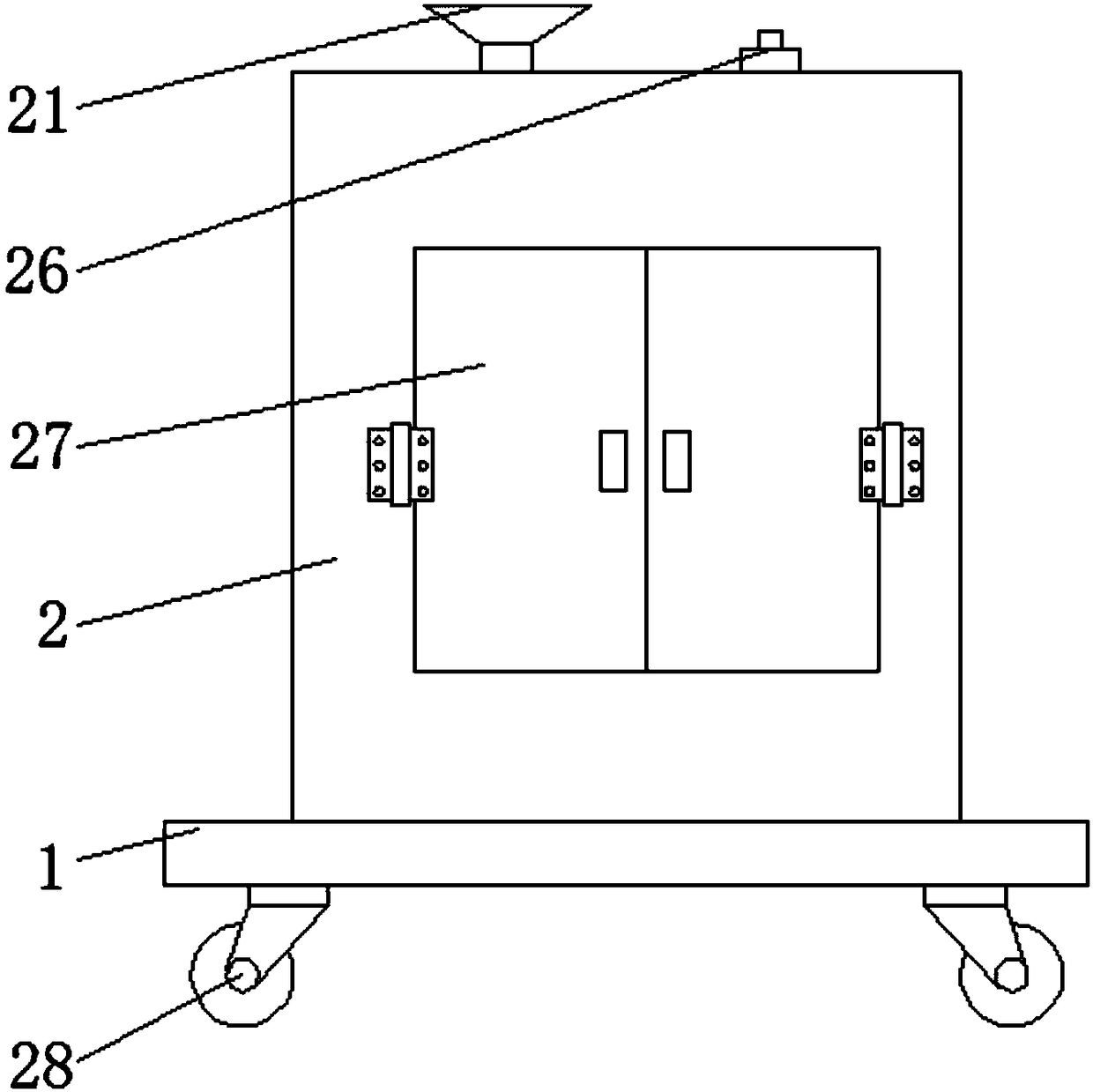

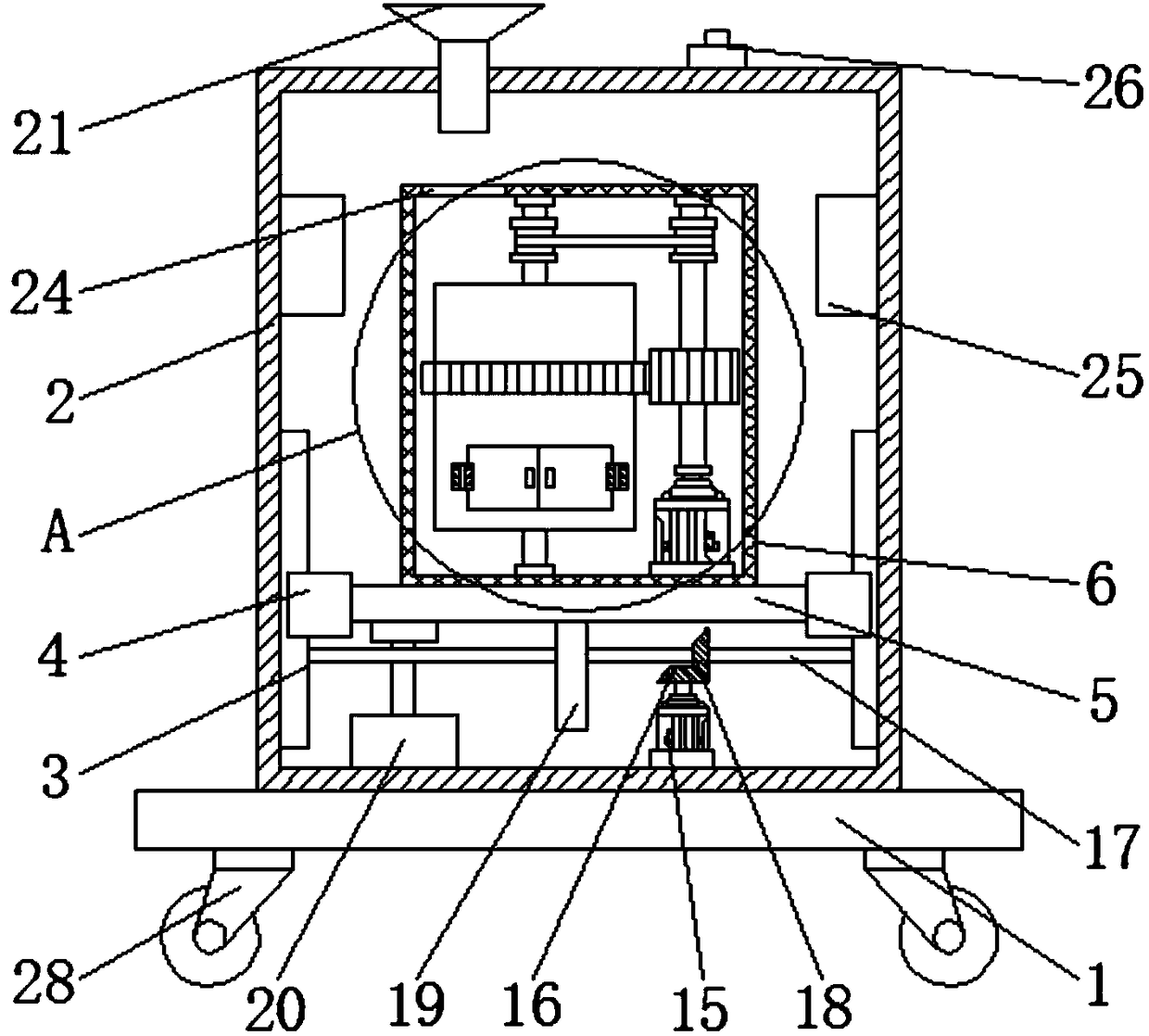

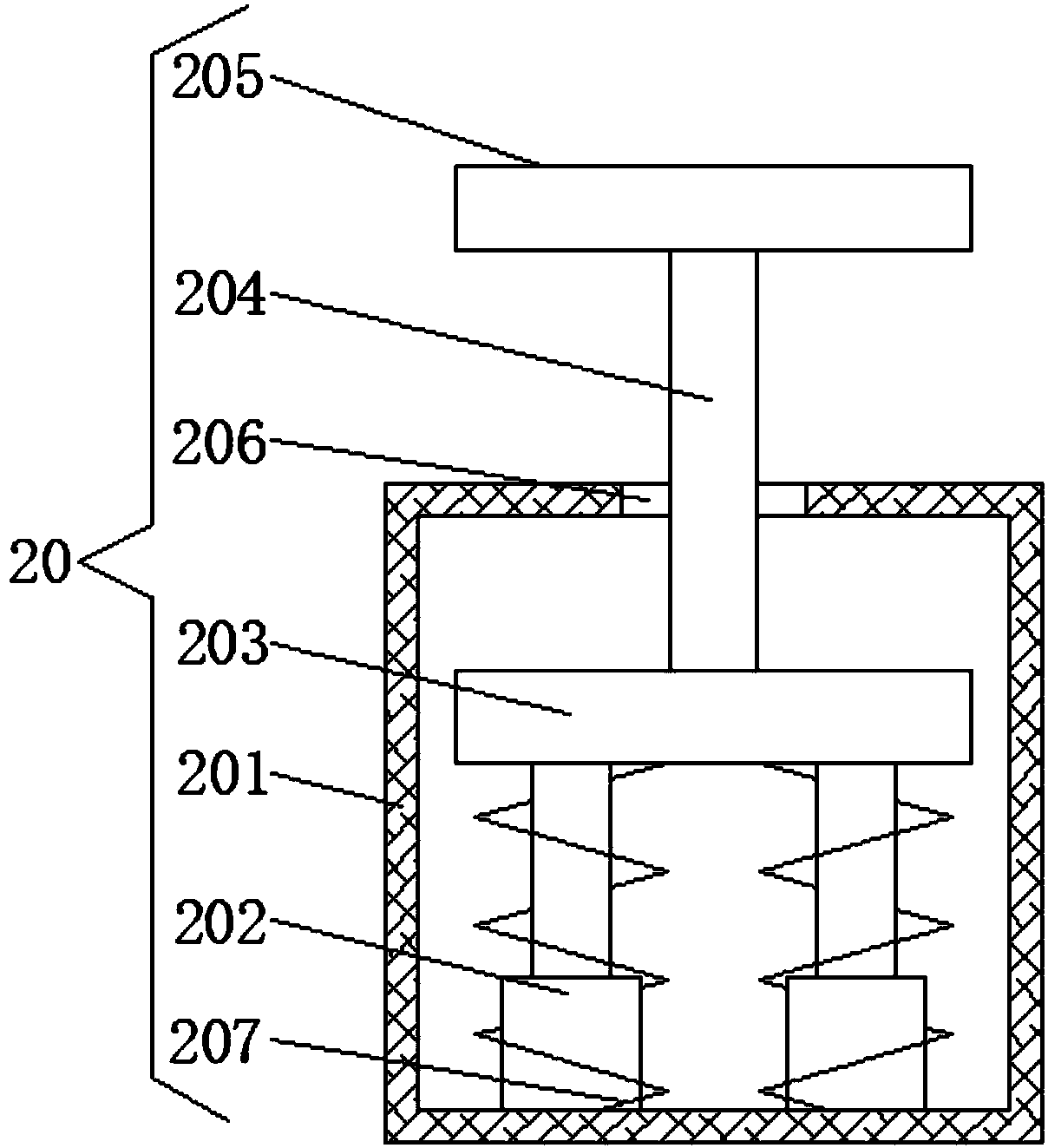

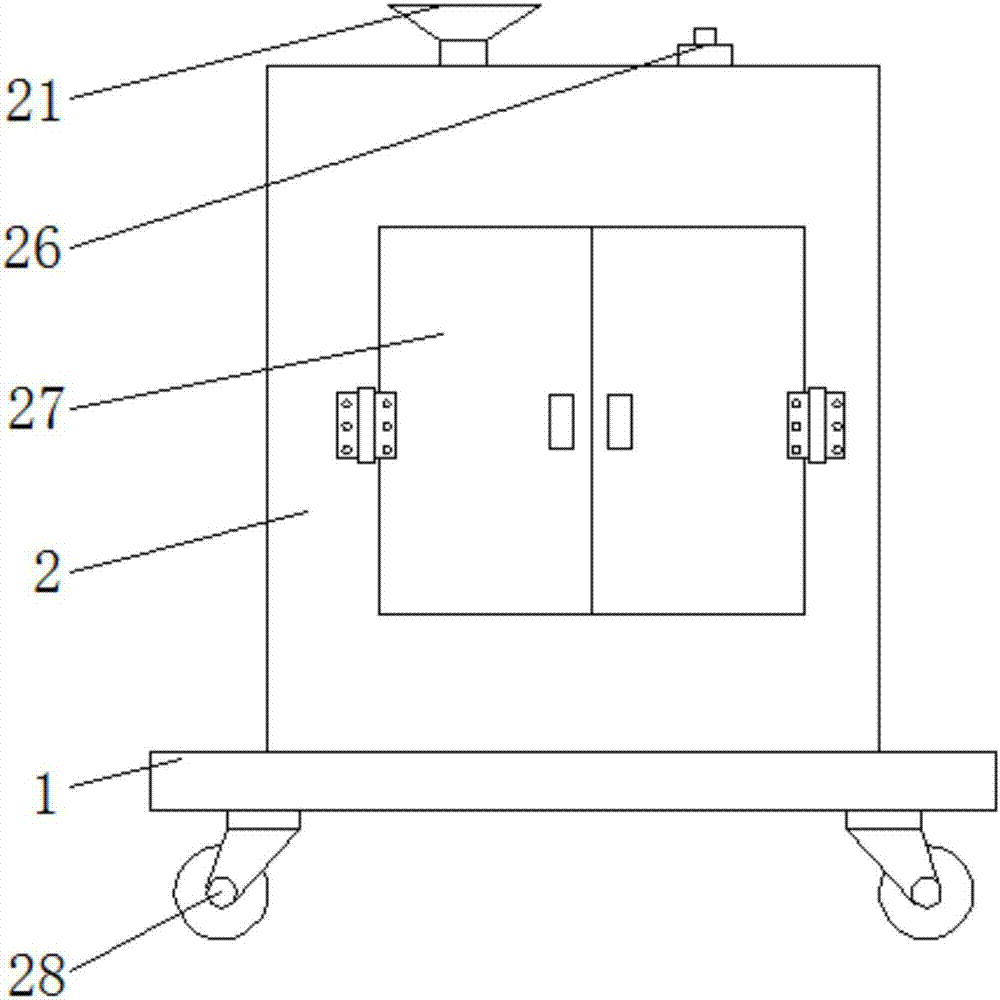

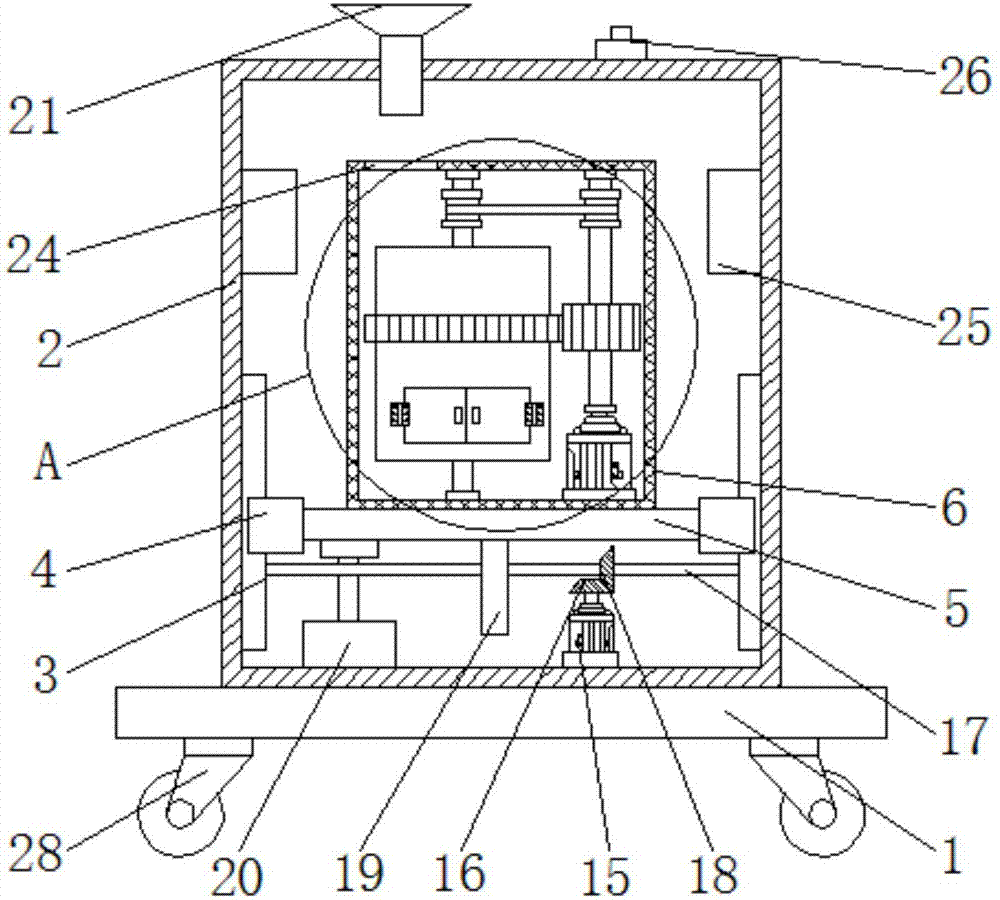

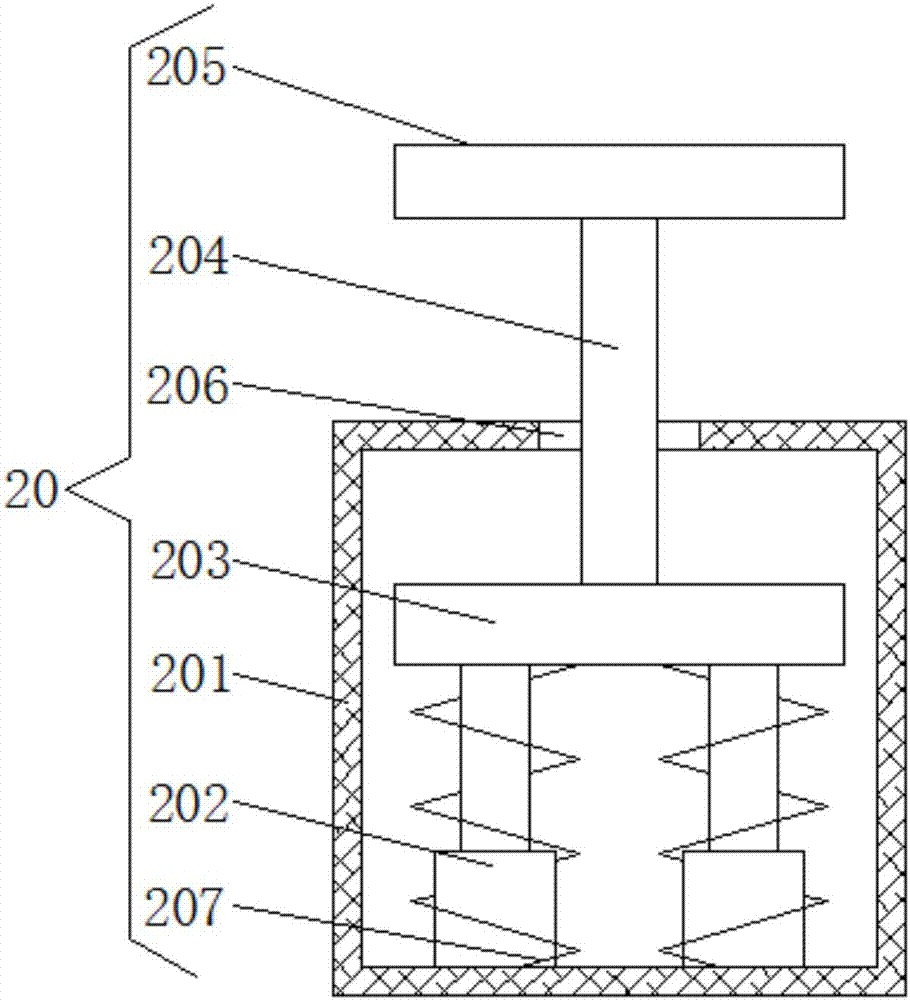

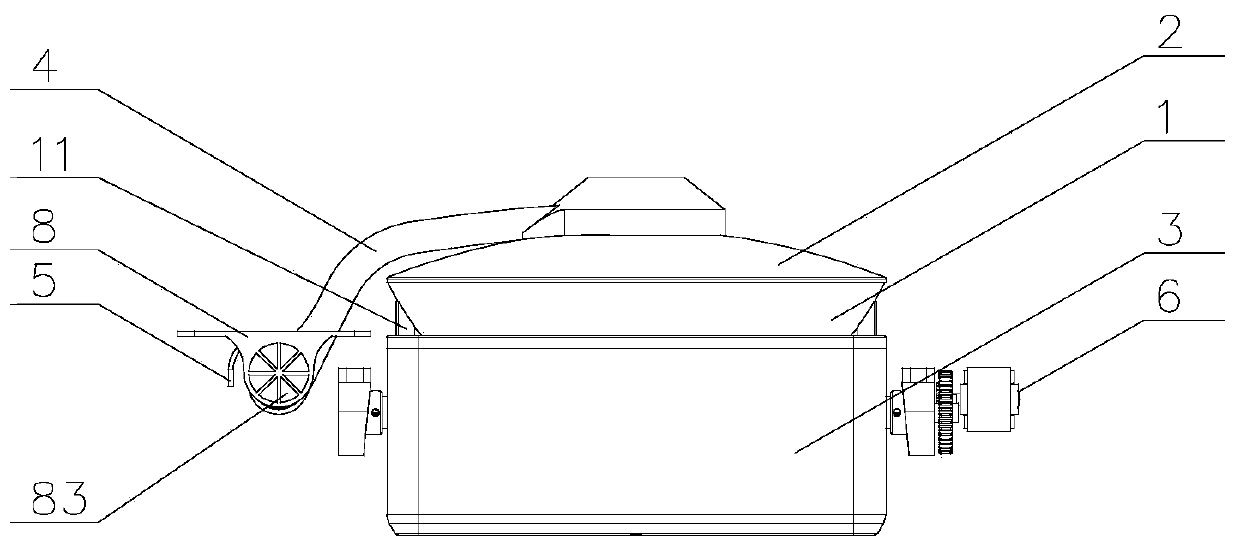

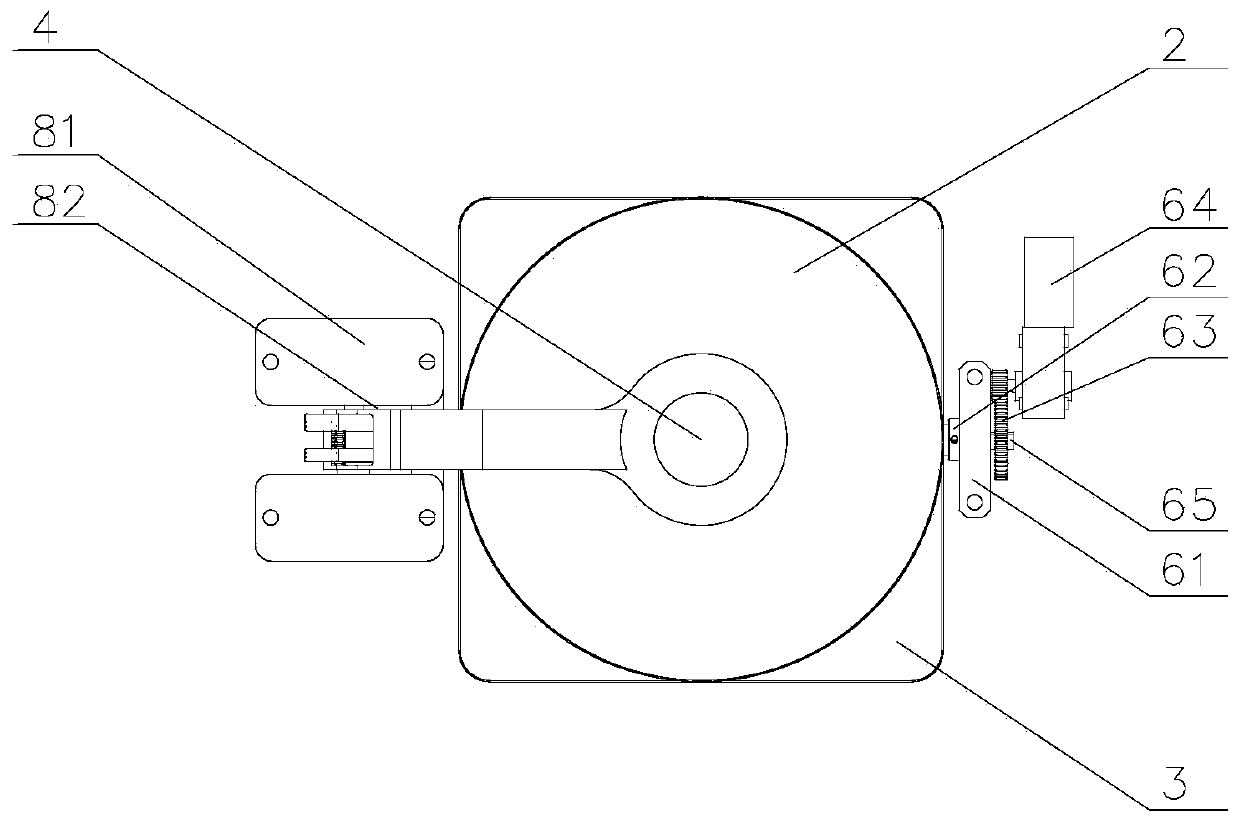

Intelligent cooking machine based on Internet of Things technology

PendingCN108294606ASave spaceRealize the intelligent integration processVessels with intergral heatingInternet of ThingsEngineering

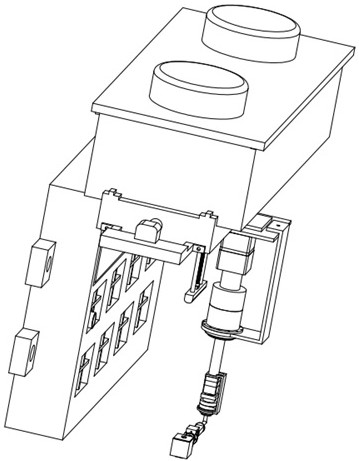

The invention provides an intelligent cooking machine based on an Internet of Things technology. The intelligent cooking machine includes an Internet of Thing control system, a pot body, bearing brackets located on both sides of the pot body, a seasoning adding mechanism, a loading mechanism and a feeding mechanical arm cooperating with the loading mechanism for use. The pot body includes an innerpot and a casing; the bottom of the casing is provided with a rotating device for the inner pot to achieve the rotation, and an electromagnetic heating device for heating is arranged around the innerpot; the bearing brackets are disposed on the two sides of the casing and provided with rotating shafts connected with the casing, respectively. An overturning device is disposed in a bearing seat and used for tilting and fixing the pot body in the vertical direction; and the Internet of Thing control system is used for controlling operations of the electromagnetic heating device, the overturningdevice, the seasoning adding mechanism, the loading mechanism and the feeding mechanical arm. According to the intelligent cooking machine, the separate addition of different food materials, the automatic filling of the seasoning, the stir-fry action by the operation of the pot body itself can be achieved, and the intelligent control of the cooking process is performed by the combination of the Internet of Thing control system.

Owner:中山市杰而普智能科技有限公司

Breakage-proof tea processing device

InactiveCN112273478AScientific and reasonable structureSafe to usePre-extraction tea treatmentHollow article cleaningHorticultureEngineering

The invention discloses a breakage-proof tea processing device. A connecting support is welded to one side of the top end of a mounting support, a fixation tank is welded to the top end of the connecting support, a feeding port is welded to the top of one side of the fixation tank, a discharging pipe is fixedly connected to the middle of the bottom end of the fixation tank, and the top, corresponding to the internal position of the fixation tank, of the discharging pipe is clamped with a fixation screen cylinder; according to the present invention, with the downward pressing of a lifting roundplate, the tea leaves in the fixation screen drum are compact, and the gap between the tea leaves is reduced, such that the water loss speed of the tea leaves during the fixation process is effectively reduced, and the charring phenomenon of the tea leaves with the low water content is avoided; the breakage-proof tea processing device ensures that the tea leaves after fixation still have sufficient moisture, ensures that the tea leaves on the inner and outer rings of the fixation screen cylinder can be uniformly heated, and can discharge surplus water vapor accumulated in the fixation tank during next pressing, optimizes the fixation process of the tea leaves, ensures high-quality fixation of the tea leaves, and improves the fixation quality of the tea leaves.

Owner:韦世林

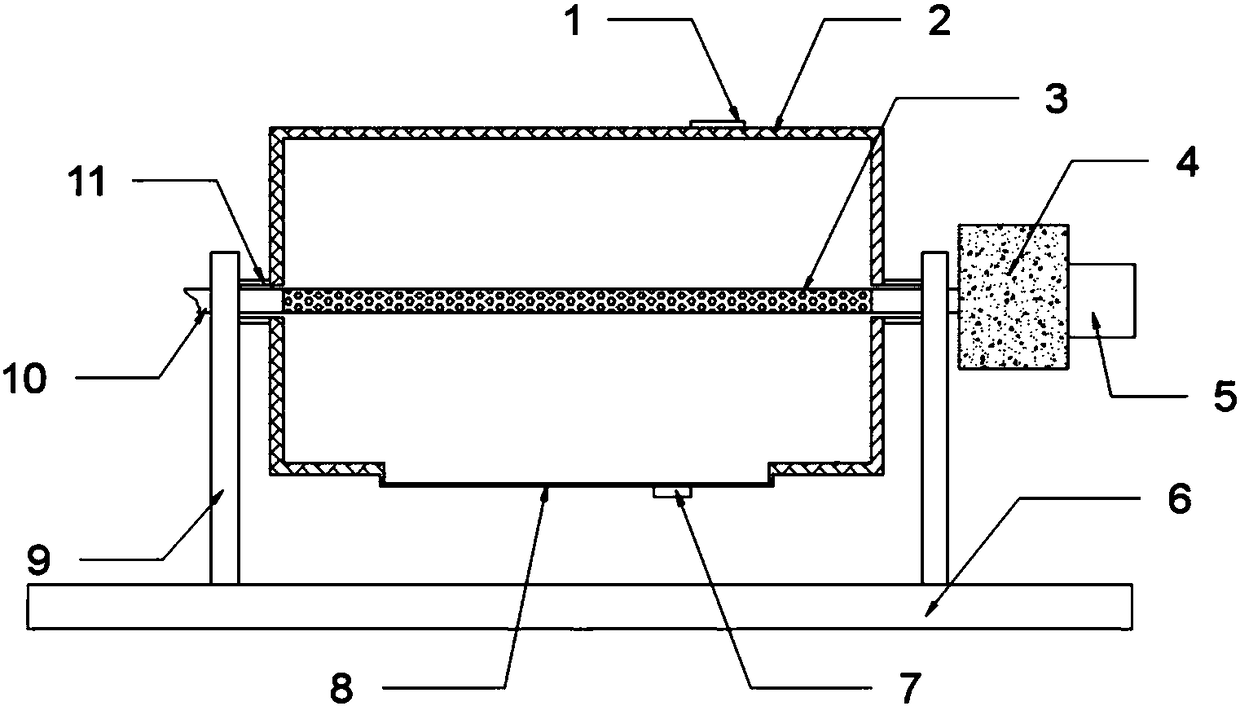

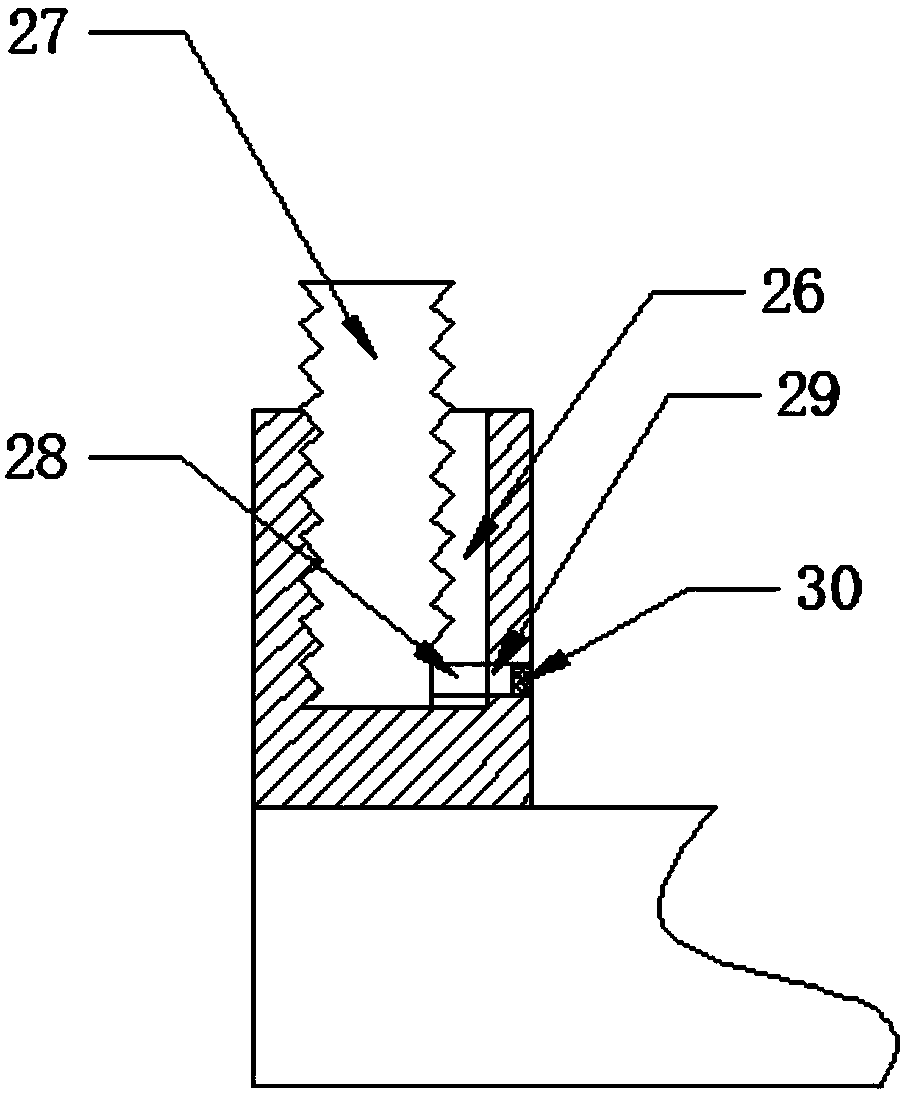

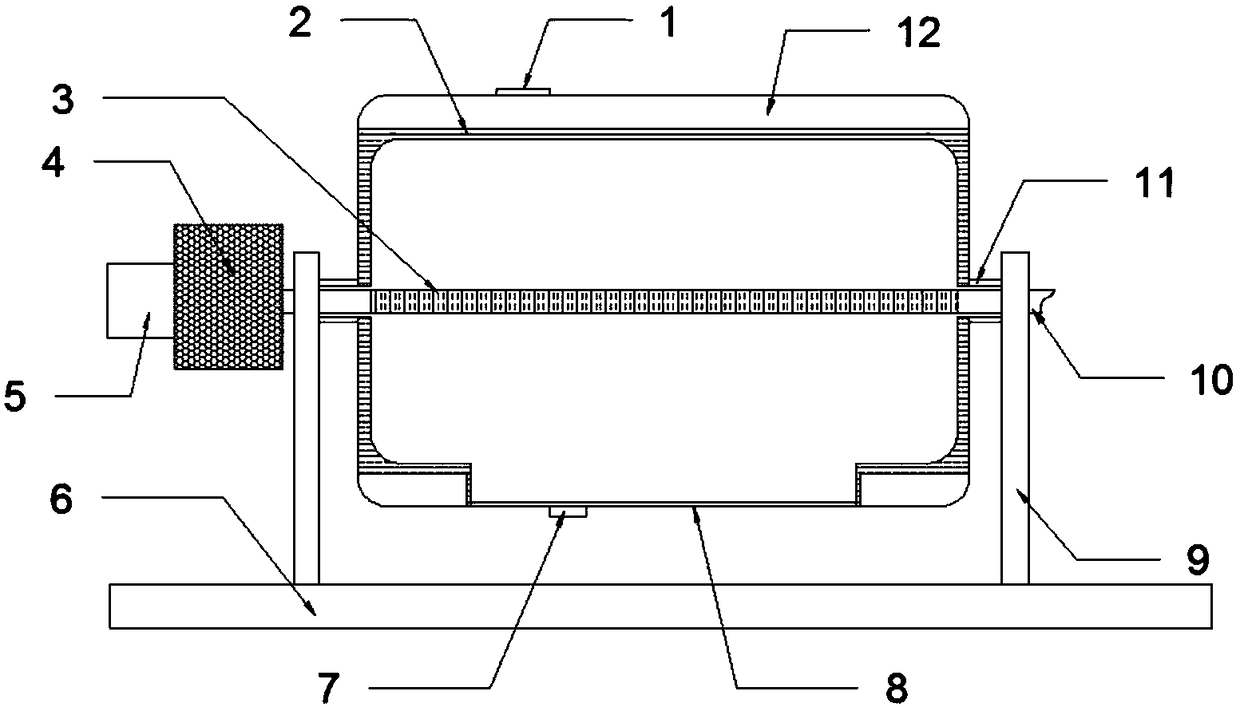

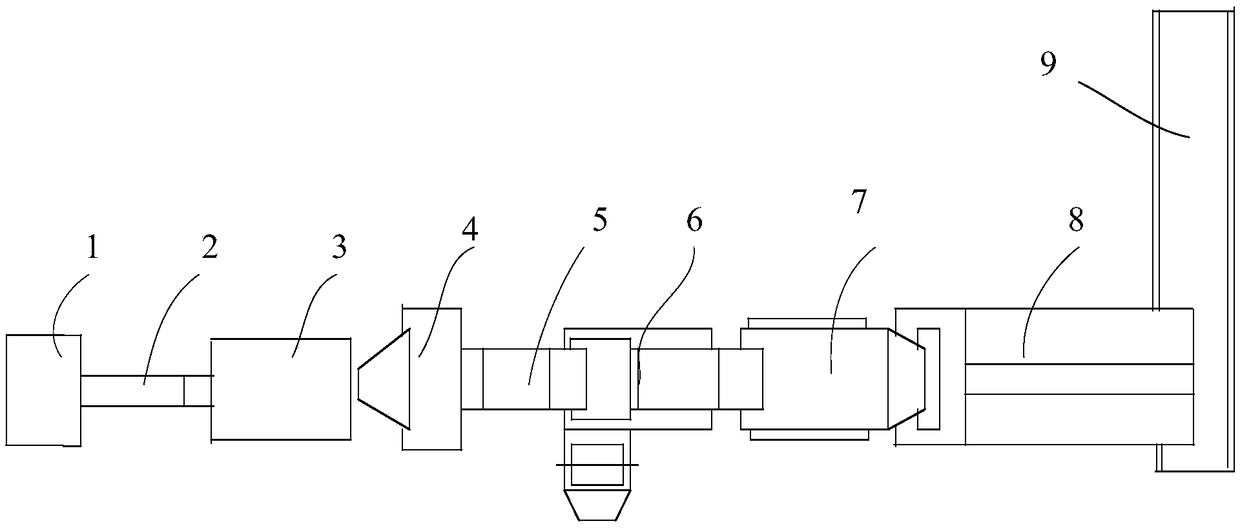

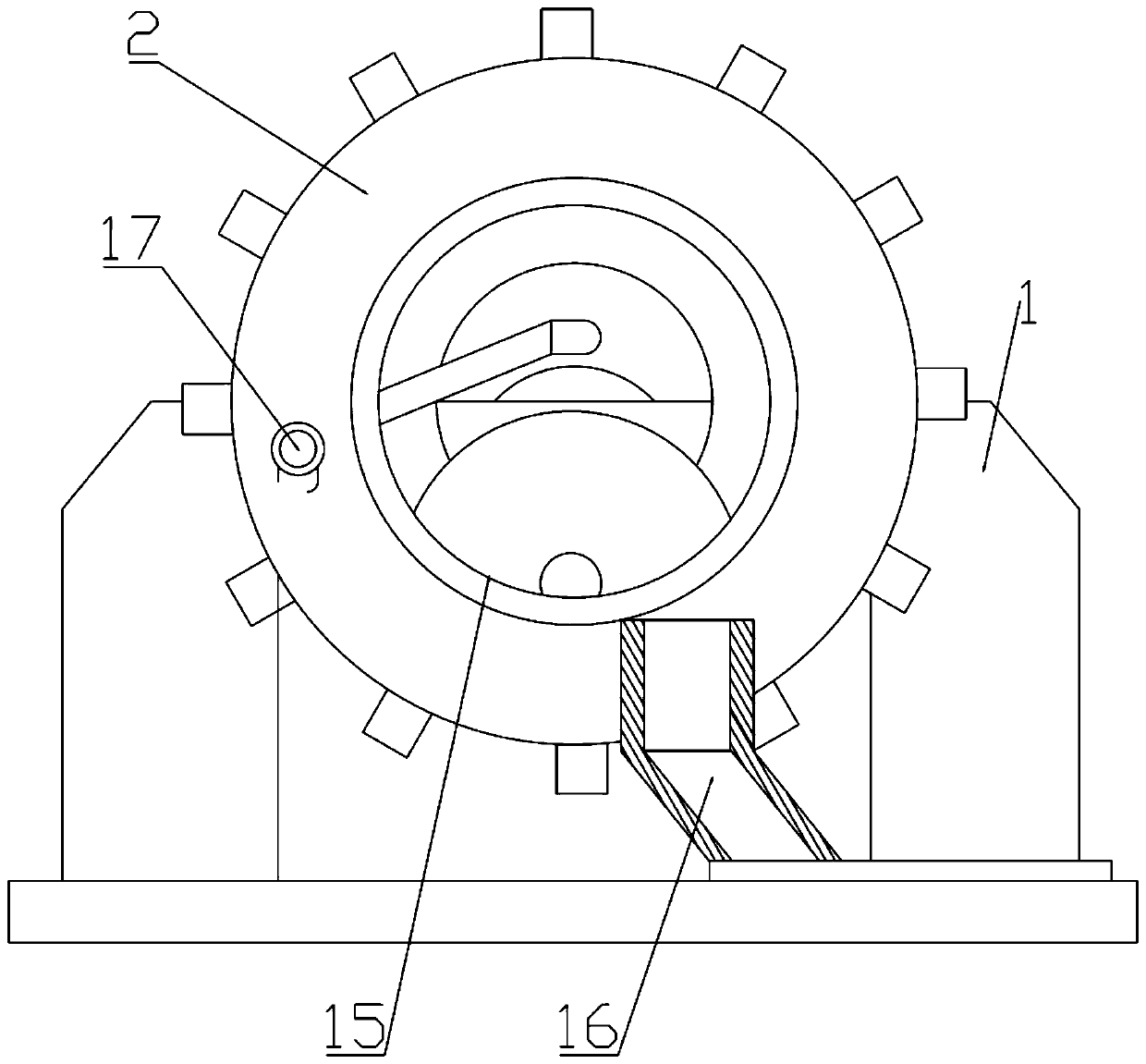

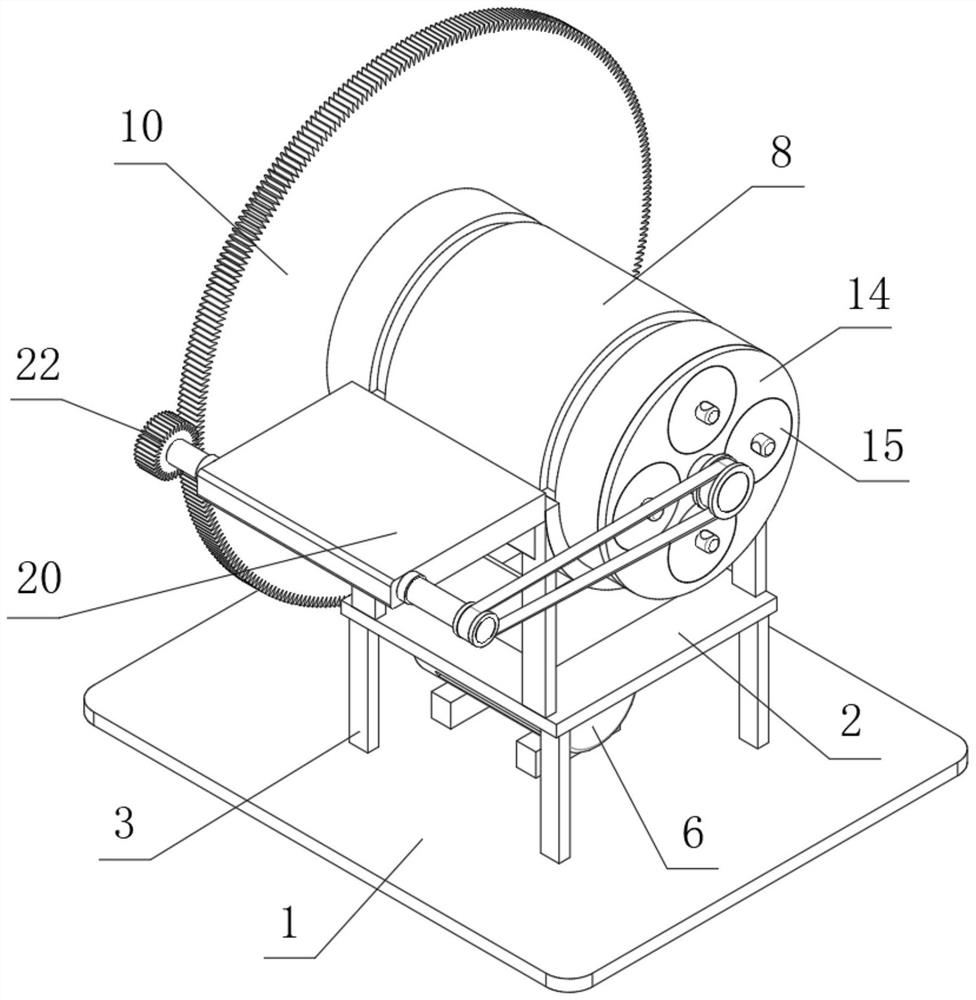

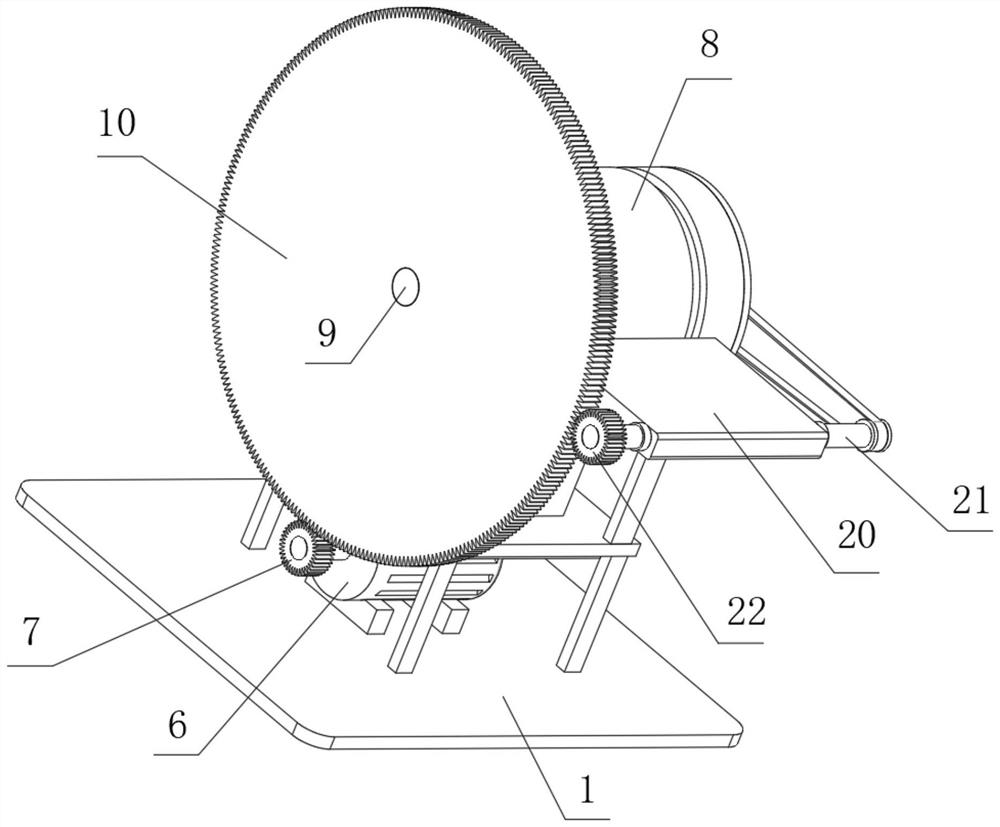

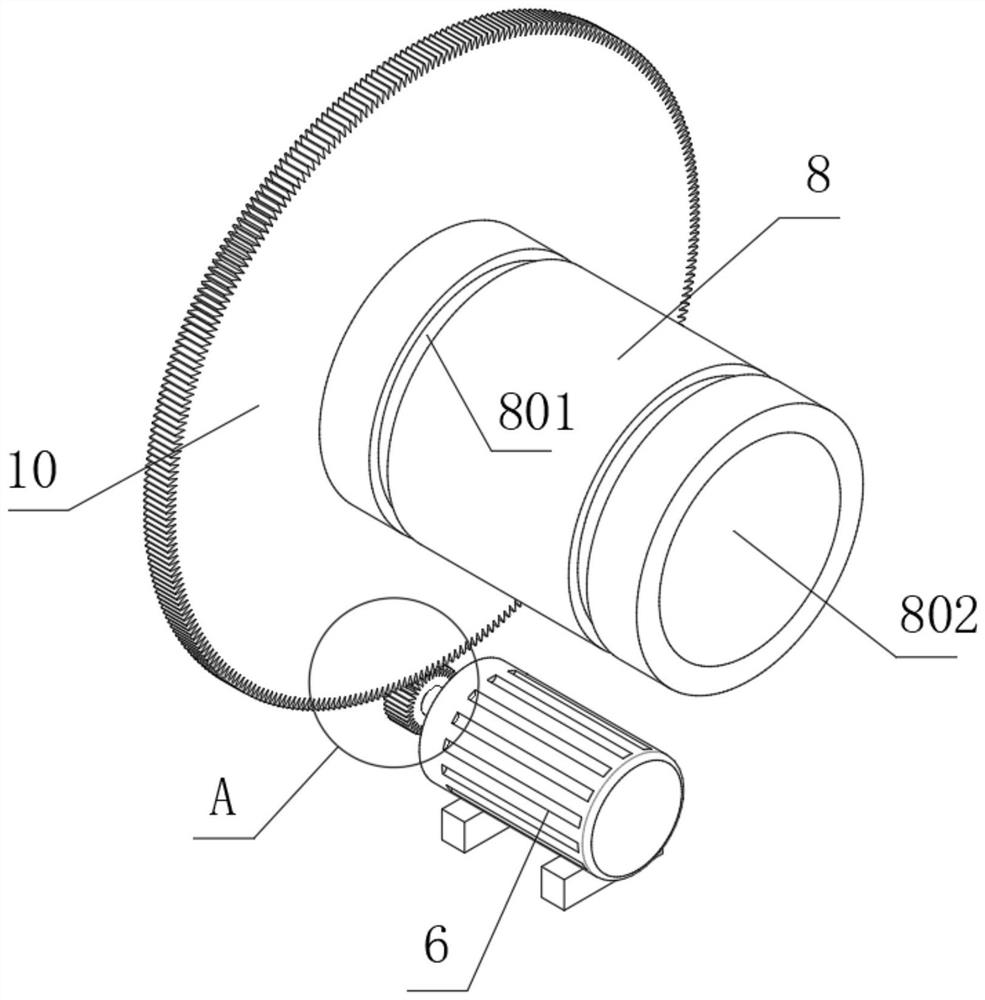

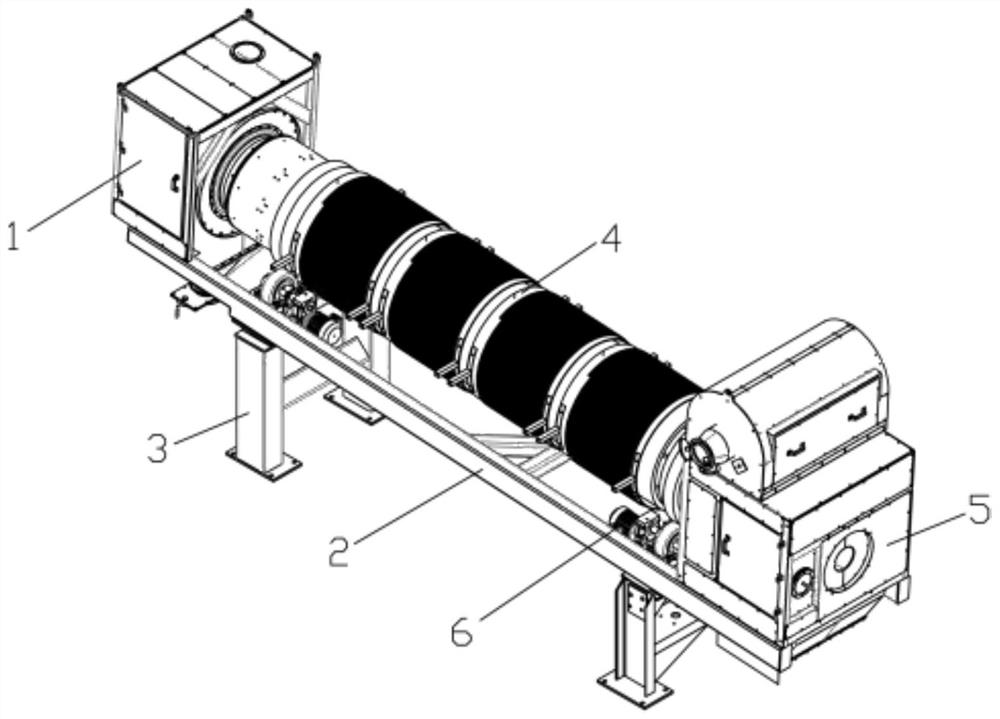

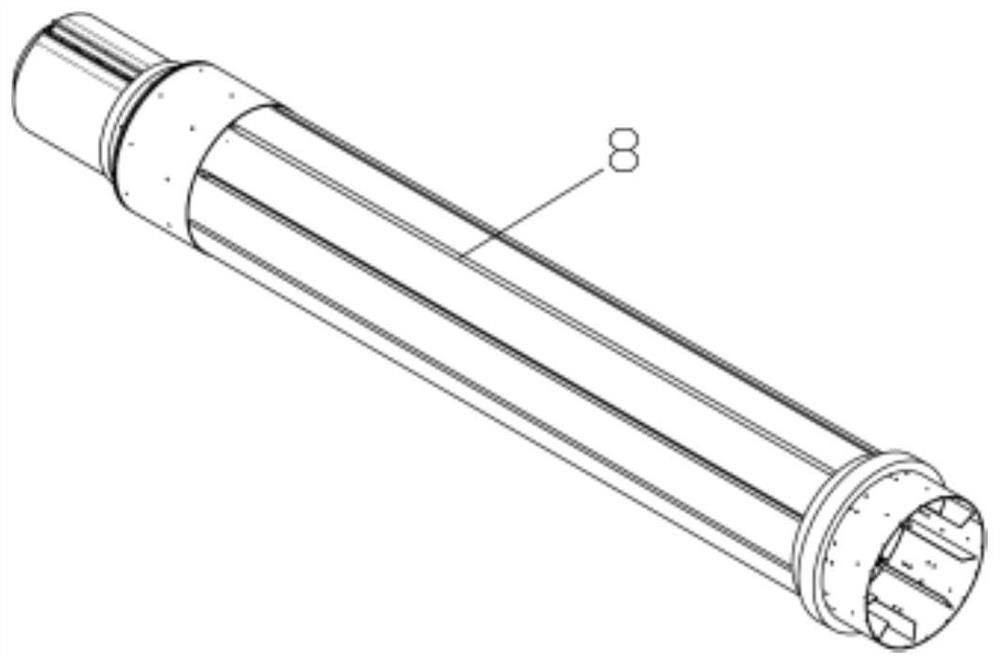

Negative pressure type roller dryer

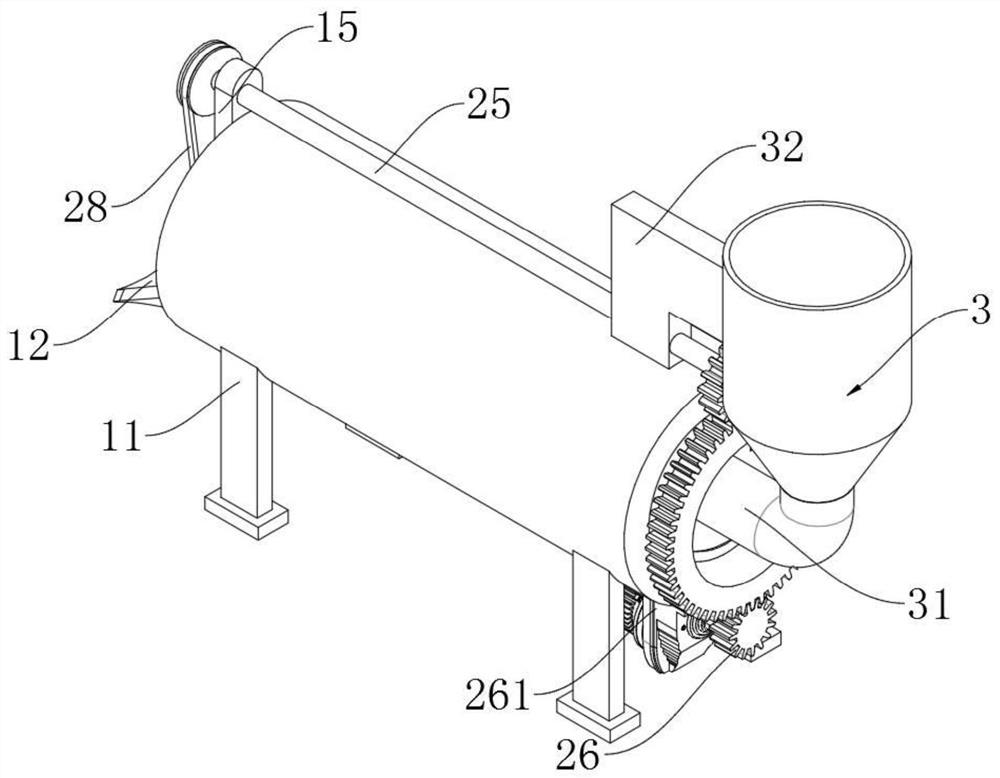

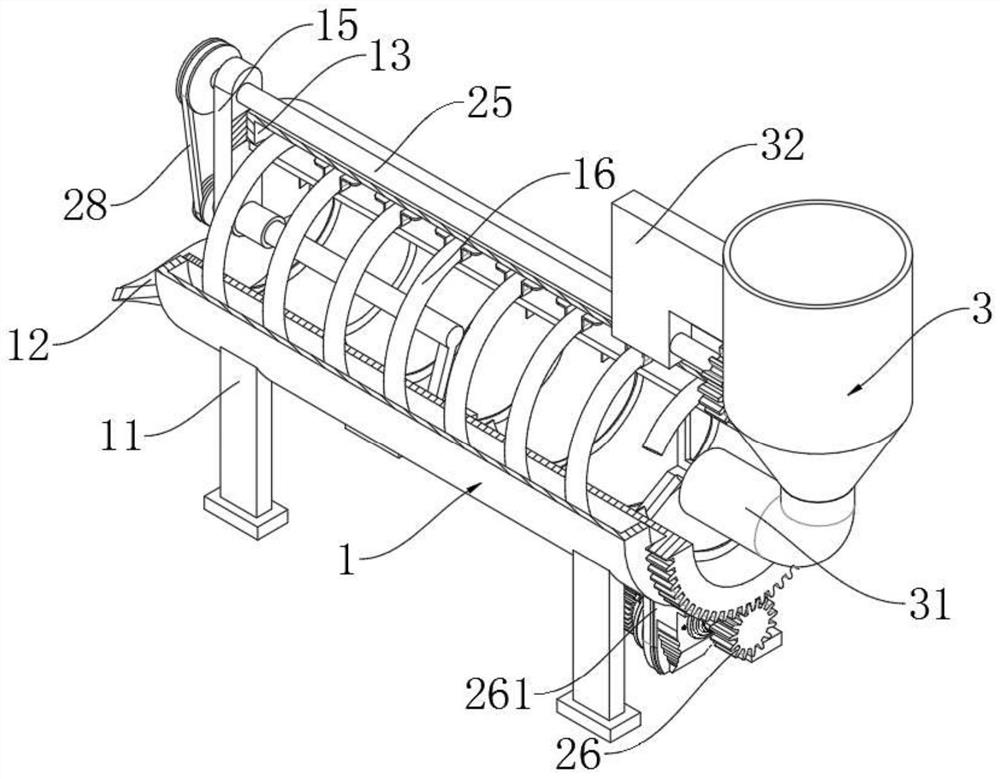

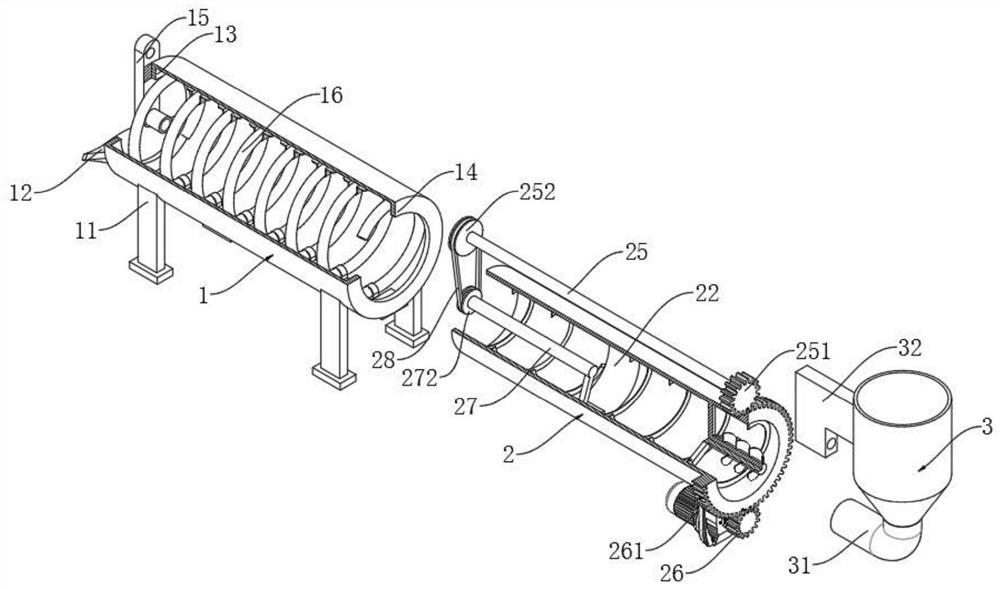

InactiveCN108413735AReduce humidityRelieve pressureDrying solid materials with heatDrying gas arrangementsPulp and paper industryMoisture

The invention relates to a negative pressure type roller dryer. The negative pressure type roller dryer comprises a base, supports and a drying barrel; the supports are arranged on the base; the drying barrel is in rotation fit with the supports through shaft rods; a feeding hole is formed in the top of the drying barrel; a discharge port is formed in the bottom of the drying barrel; shaft holes are formed in the shaft rods; a heating layer is integrated in the barrel wall of the drying barrel; a ventilating pipe with a hollow structure is arranged in a barrel cavity of the drying barrel; thetwo ends of the ventilating pipe stretch out of the shaft holes and penetrate out of the supports; and ventilating holes are formed in the parts, located in the drying barrel, of the pipe wall of theventilating pipe. The humidity and the pressure in the drying barrel can be effectively reduced, and discharge of moisture in grains is accelerated; the moisture of air in the drying barrel can be pumped, so that the situation that the grains absorb water and are wetted back in the cooling process is avoided; the grains in the drying barrel can be subjected to sampling analysis, so that a destination of drying operation is accurately grasped; and the final drying quality of the grains is ensured.

Owner:郑州龙威电气安装有限公司

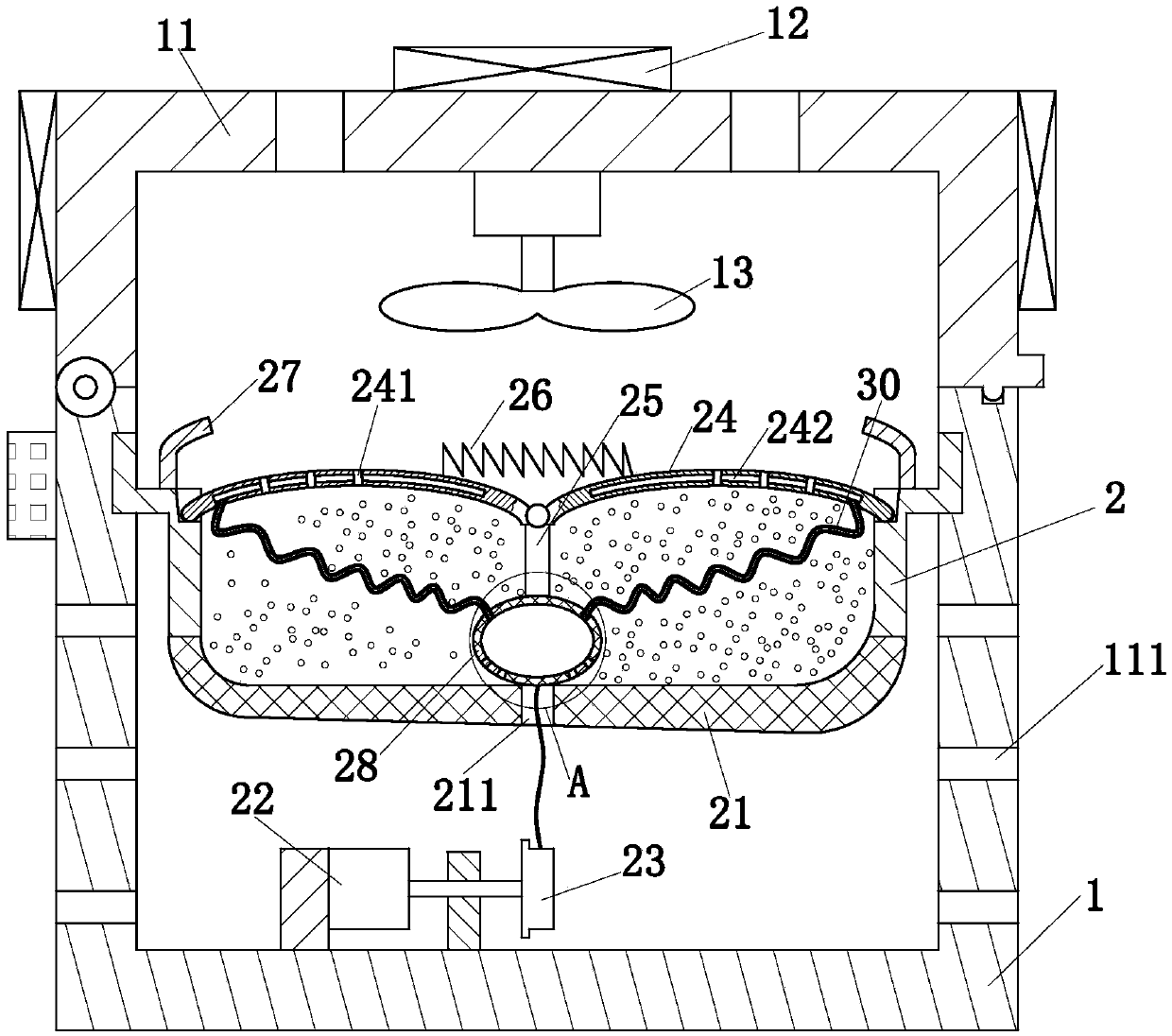

Energy-saving air purification device for indoor use

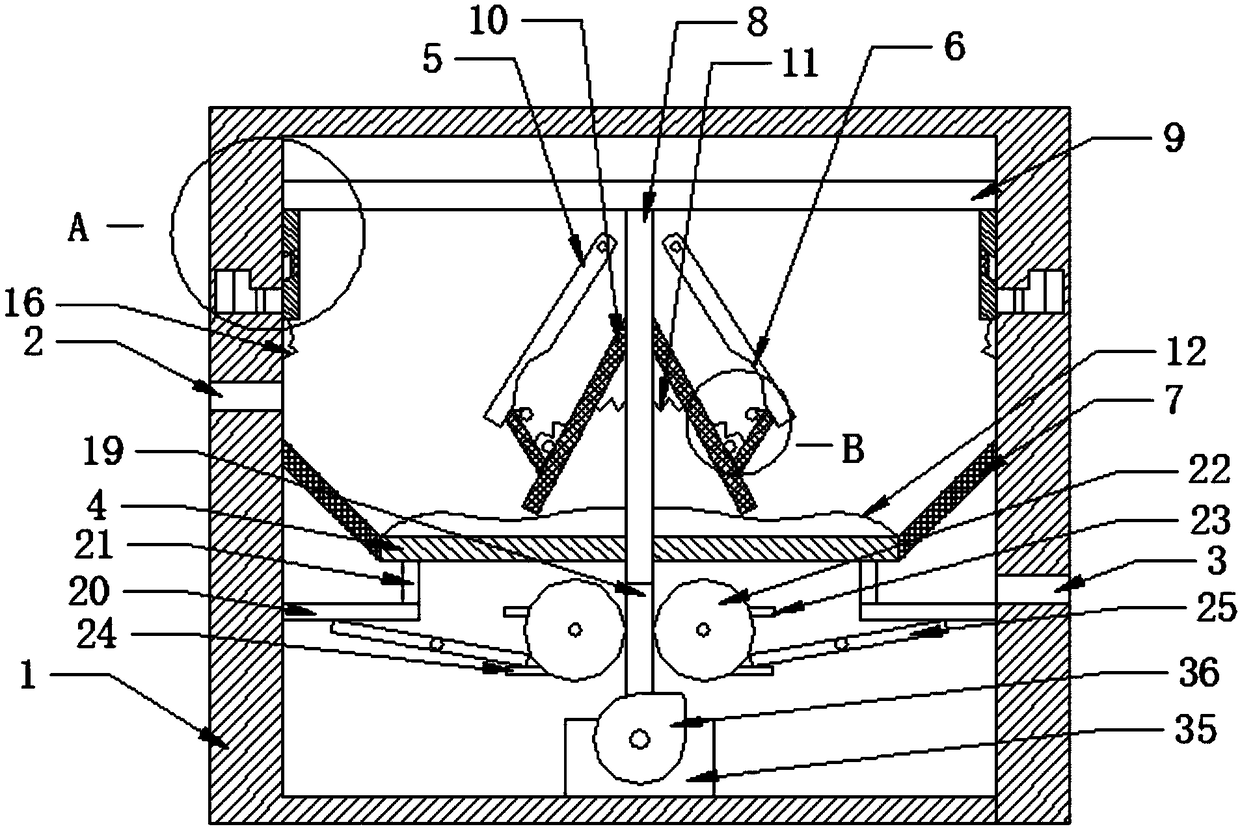

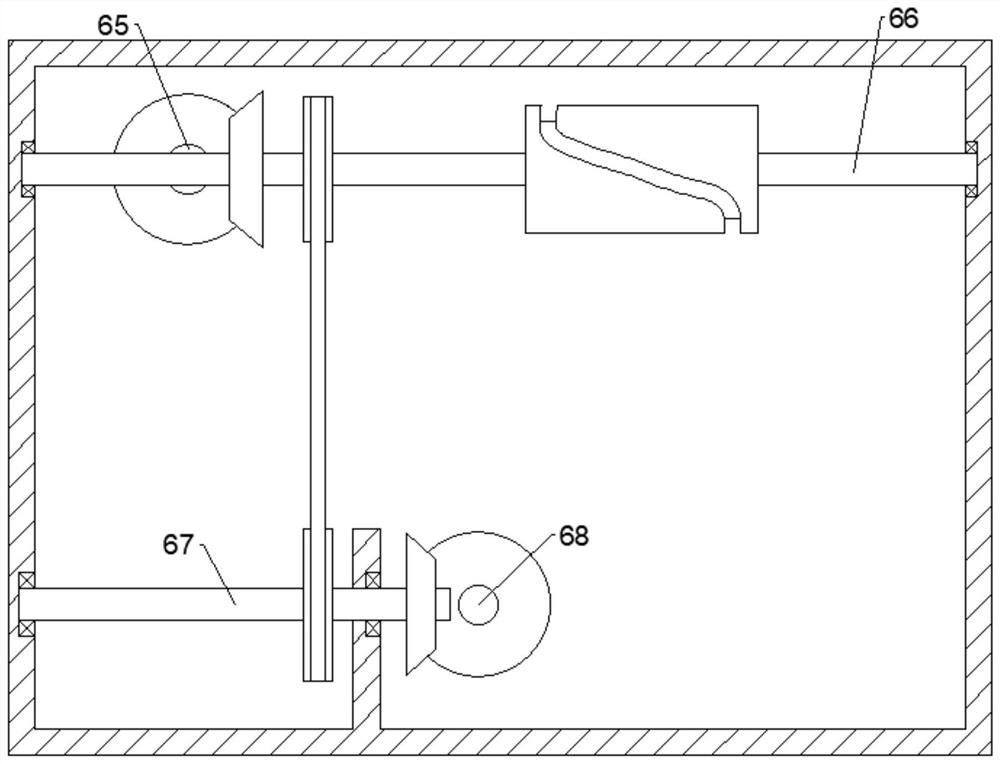

ActiveCN109529535AAchieve stir fryImprove exposure efficiencyGas treatmentDispersed particle separationEnvironmental resistanceActivated carbon

The invention belongs to the technical field of air purification, in particular to an energy-saving air purification device for indoor use. The device includes a square box, a lid hinged with and covering the square box, a solar power board arranged on the square box or the lid, a controller, an electric fan disposed on the inner top wall of the lid and an inner box fixed to the upper part of thesquare box. The square box and the lid are provided with ventilation holes. The inner box includes an elastic box bottom the thickness of which increases from one side to the other side evenly. The bottom center of the elastic box bottom is provided with a vent hole, and a driving motor and a rope winding roller connected to a motor shaft are disposed below the elastic box bottom. The rope windingroller is connected to the elastic box bottom through a rope. The driving motor is used for driving rope winding by the rope winding roller so that the elastic box bottom is pulled downward by the rope and activated carbon particles are raised by the elastic box bottom to turn over the activated carbon particles. The device is green, energy-saving, practical, and capable of improving activity ofactivated carbon particles and improving indoor air environment better.

Owner:空净视界智能科技有限公司

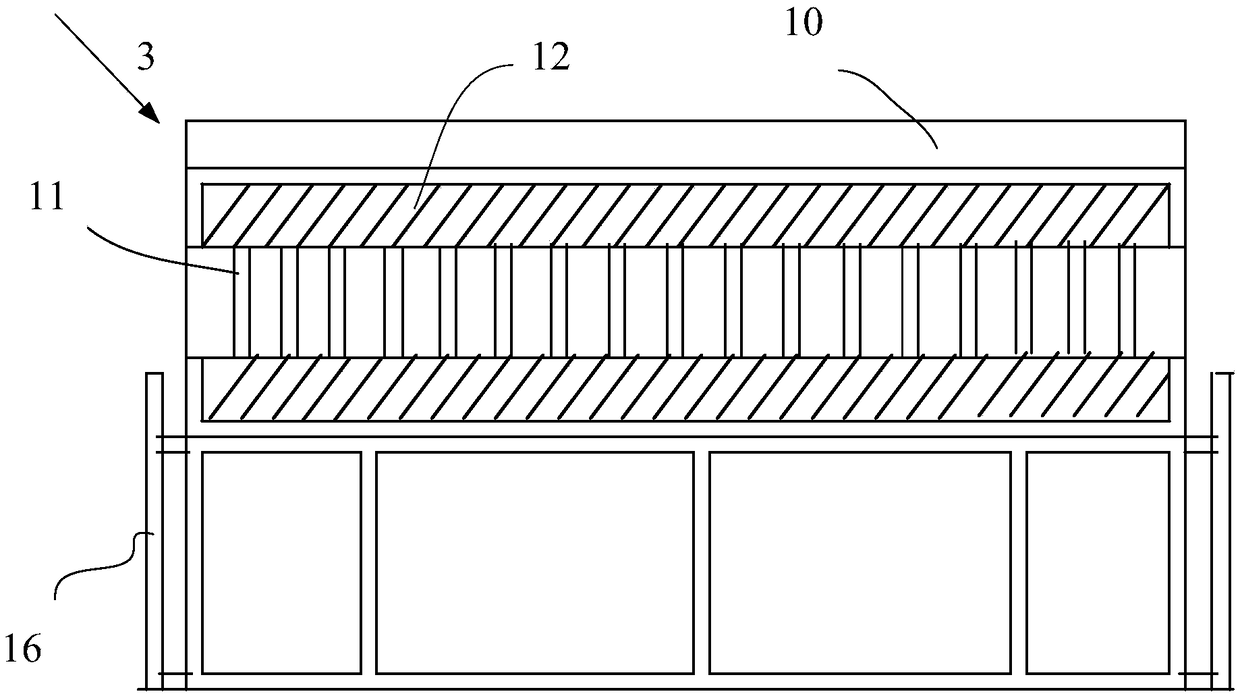

Roller type tea leaf drying box

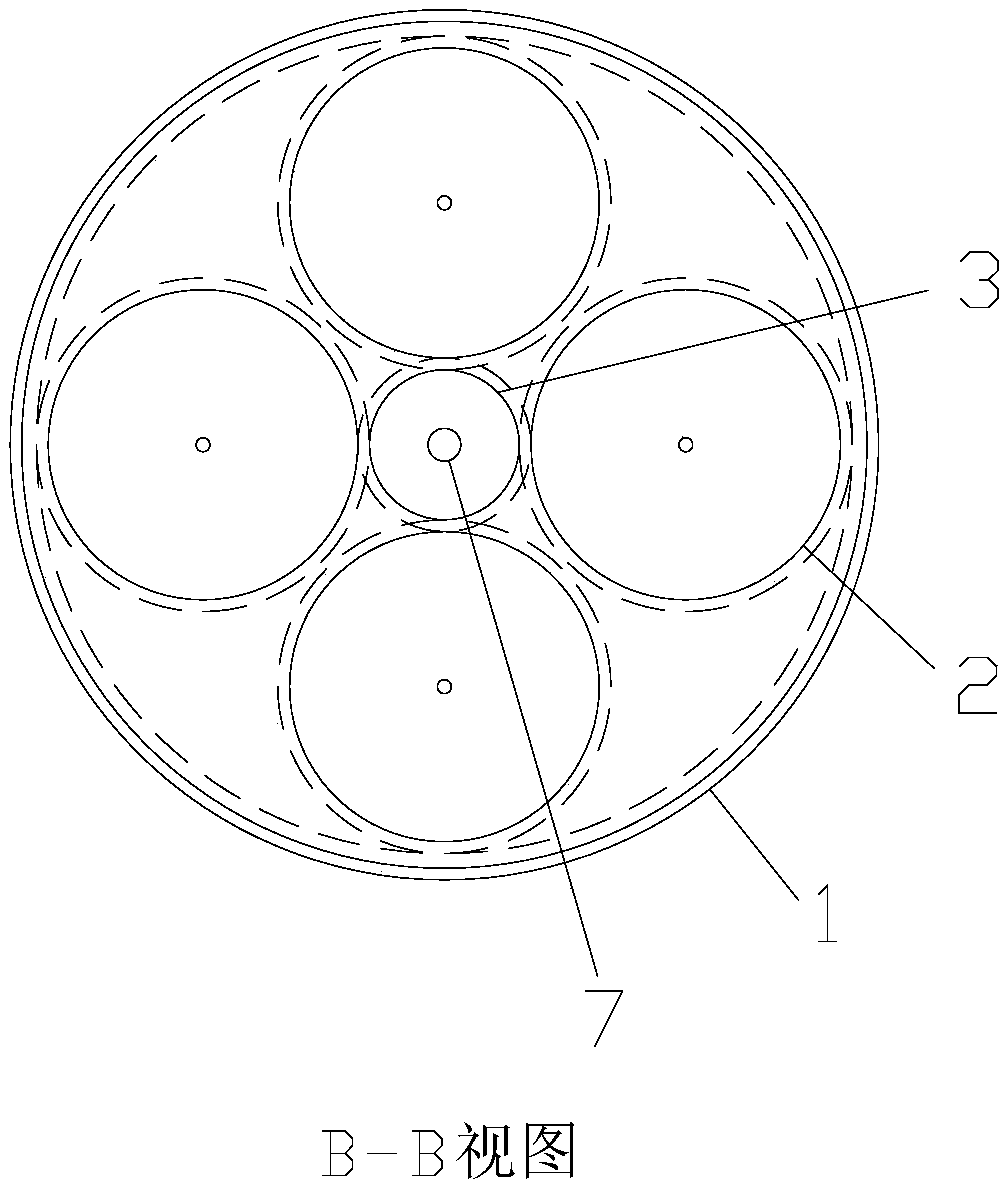

InactiveCN109042948AAchieve stir fryHigh yieldPre-extraction tea treatmentAgricultural engineeringHot Temperature

The invention discloses a roller type tea leaf drying box and relates to the technical field of tea leaf drying equipment. The roller type tea leaf drying box comprises an outer barrel, wherein the outer barrel is internally provided with a plurality of drying inner barrels for containing tea leaves; the drying inner barrels can do revolution motion along the middle axis of the outer barrel; the drying inner barrels can do spinning motion along the middle axis of the drying inner barrels; a plurality of ventilation holes are formed in side walls of the drying inner barrels. According to the roller type tea leaf drying box disclosed by the invention, when the drying inner barrels do the revolution motion like a stirring paddle in an inner cavity of the stirring outer barrel, so that convolutional flow of hot air is formed in the inner cavity of the outer barrel, and a uniform hot temperature field is easily formed in the inner cavity of the outer barrel; when the drying inner barrels dothe spinning motion, the tea leaves contained in the drying inner barrels are driven to overturn and the tea leaves are overturned and fried, so that uniform heat exchange between the tea leaves andthe hot air can be realized; the heat efficiency is easy to improve and the yield of the tea leaves is also easy to improve.

Owner:ANHUI XINXUTANG TEA CO LTD

Tea screening equipment

ActiveCN108722871AAchieve stir fryEasy to separateSievingGas current separationEngineeringLinkage concept

The invention discloses tea screening equipment. The tea screening equipment comprises a box body, and the box body is provided with a feeding opening and a discharging opening. The box body is internally provided with a stirring mechanism, a storage platform and a vertical reciprocating mechanism from top to bottom in sequence. The stirring mechanism comprises swing arms, wherein the swing arms are hinged to the inner wall of the box body in a leftwards-rightwards-symmetrical manner, and the swing arms are provided with arc flow guide slots. The two sides of the storage platform are both provided with inclined nets, and the middle of the storage platform is provided with a linkage rod in a penetrated manner. The top of the linkage rod is provided with a pressing plate. The two sides of the linkage rod are both connected with supporting nets in a hinged manner, and a first spring is arranged between the supporting nets and the linkage rod. The bottom of the linkage rod is connected with the vertical reciprocating mechanism. The linkage rod is provided with an elastic metal net in the peripheral direction. The inner walls on the two sides of the box body are both provided with grooves, and the grooves are internally provided with draught fans. The inner walls on the two sides of the box body are both slidably connected with baffles, and a second spring is arranged between each baffle and the box body. The baffles are provided with air holes. The box body is further internally provided with an automatic discharging mechanism. By means of the tea screening equipment, the problem that current tea screening efficiency is low is mainly solved.

Owner:贵州省凤冈县永田露茶业有限公司

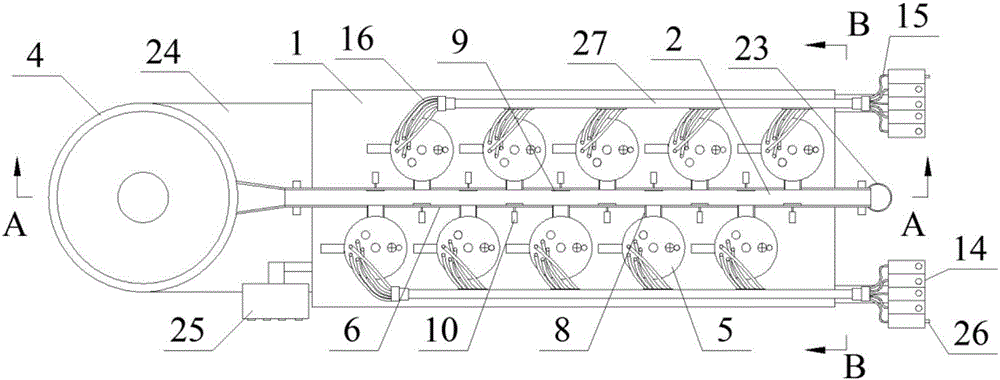

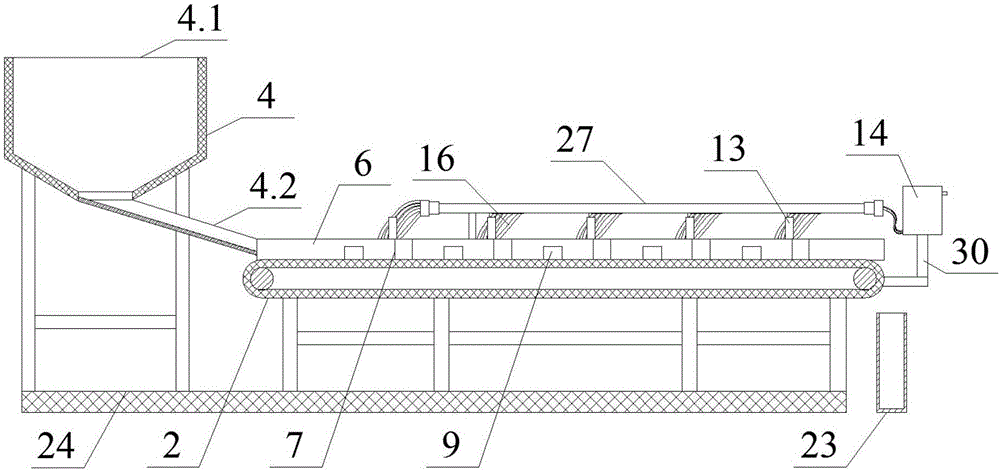

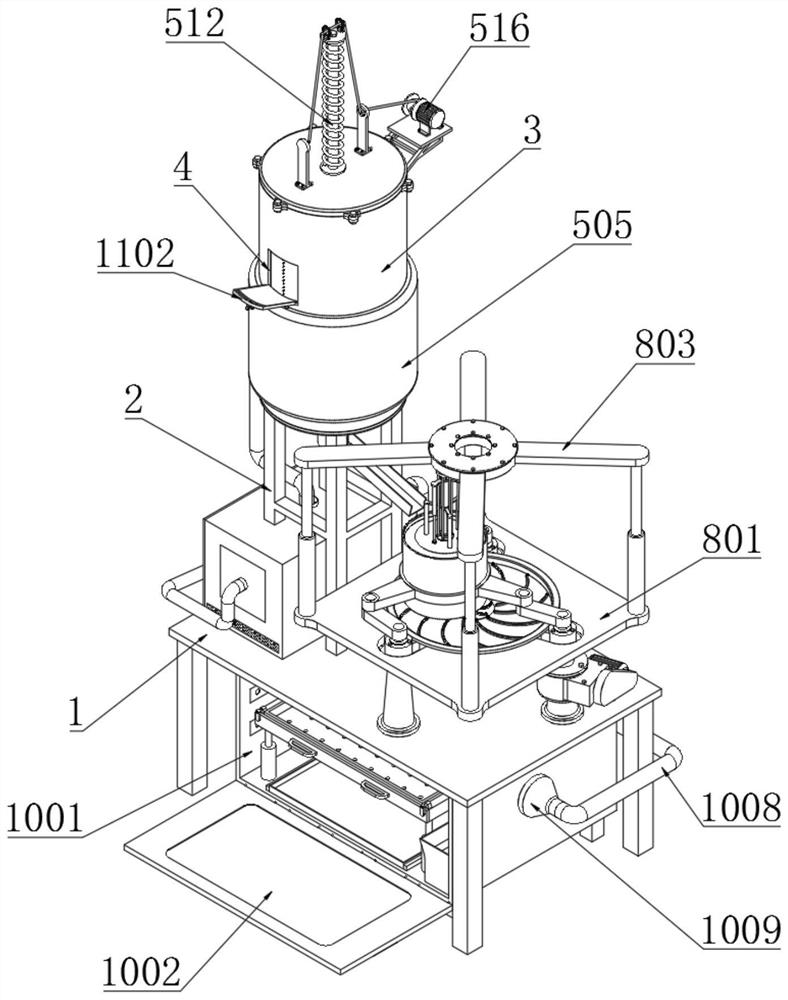

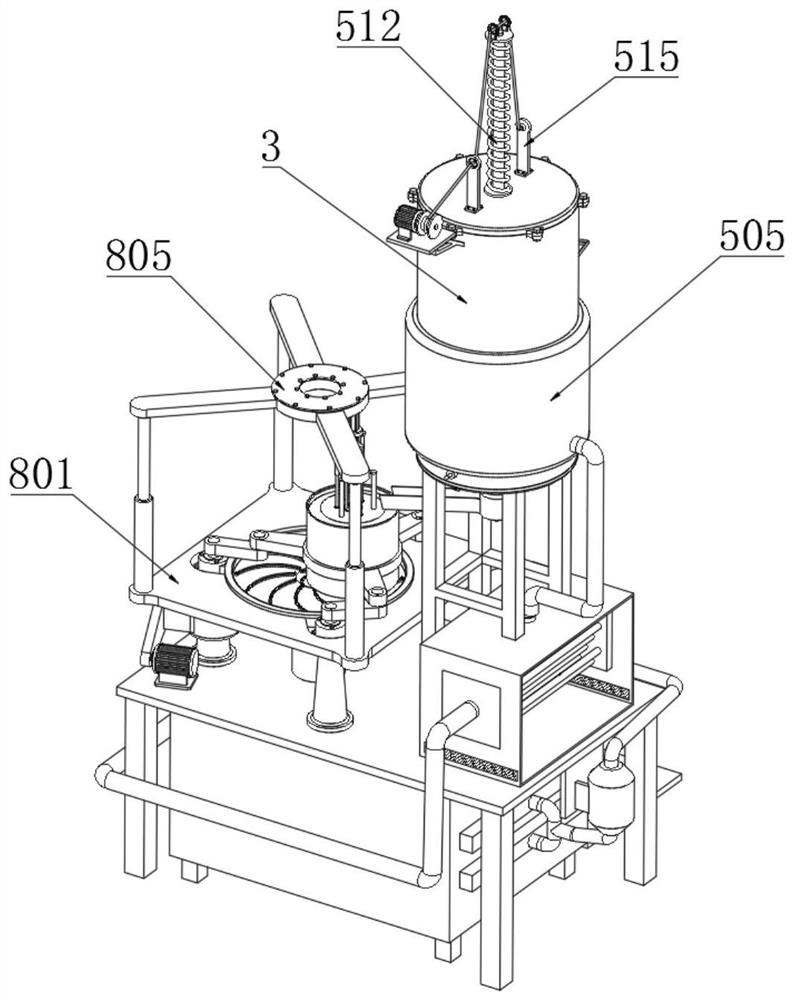

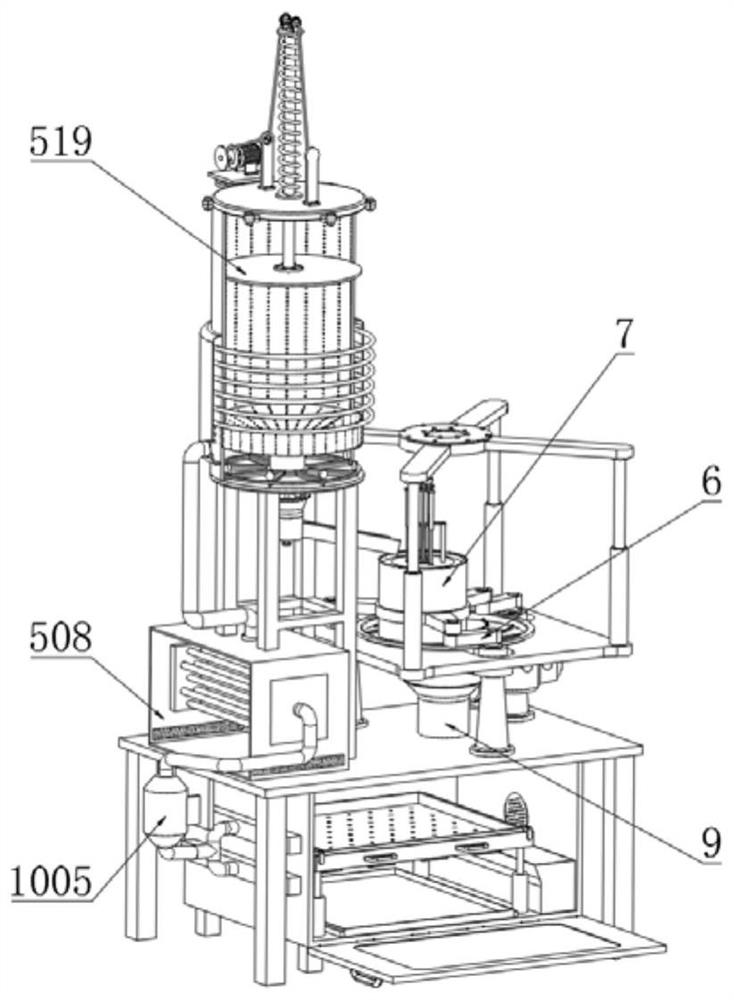

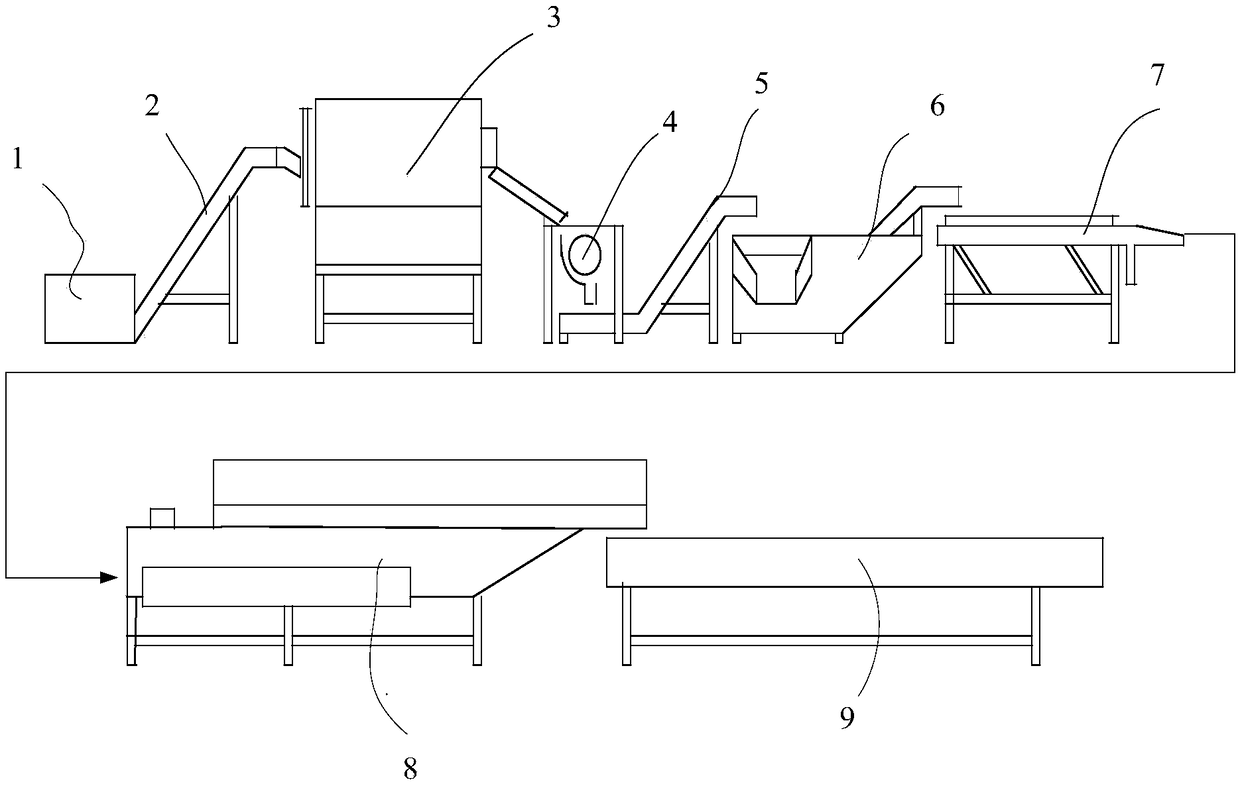

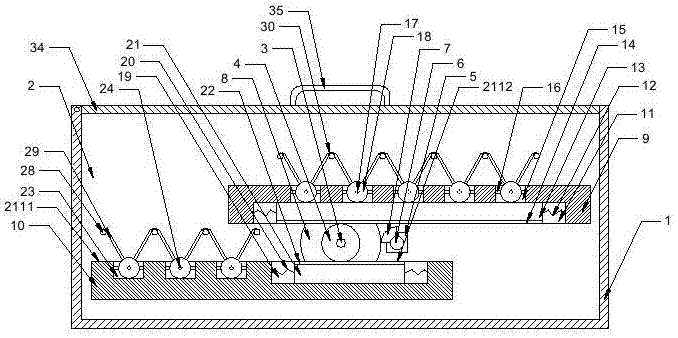

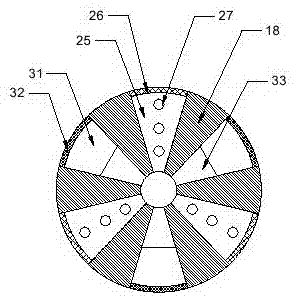

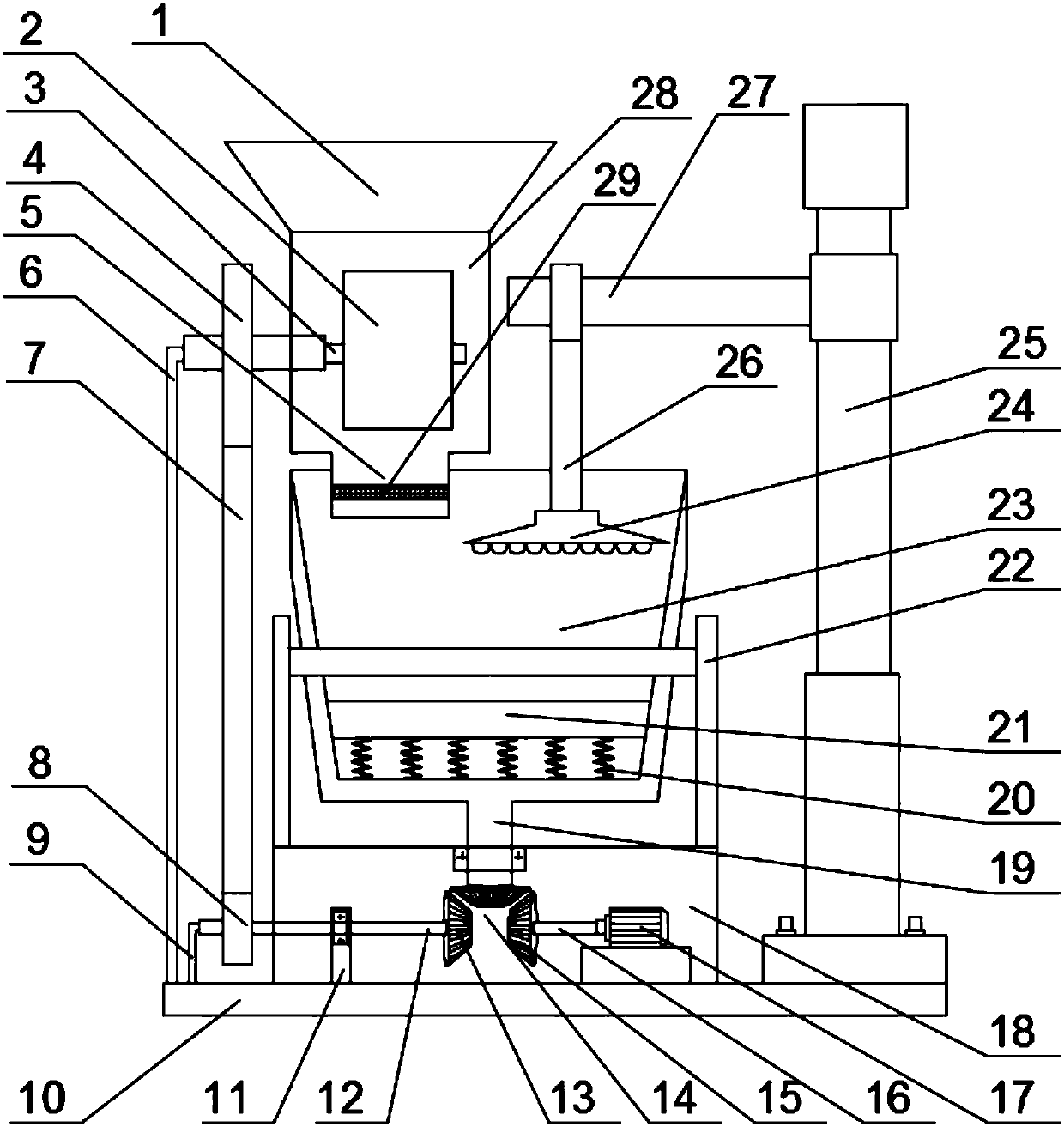

Full-automatic continuous automatic feeding and discharging tea leaf stir-frying machine and using method thereof

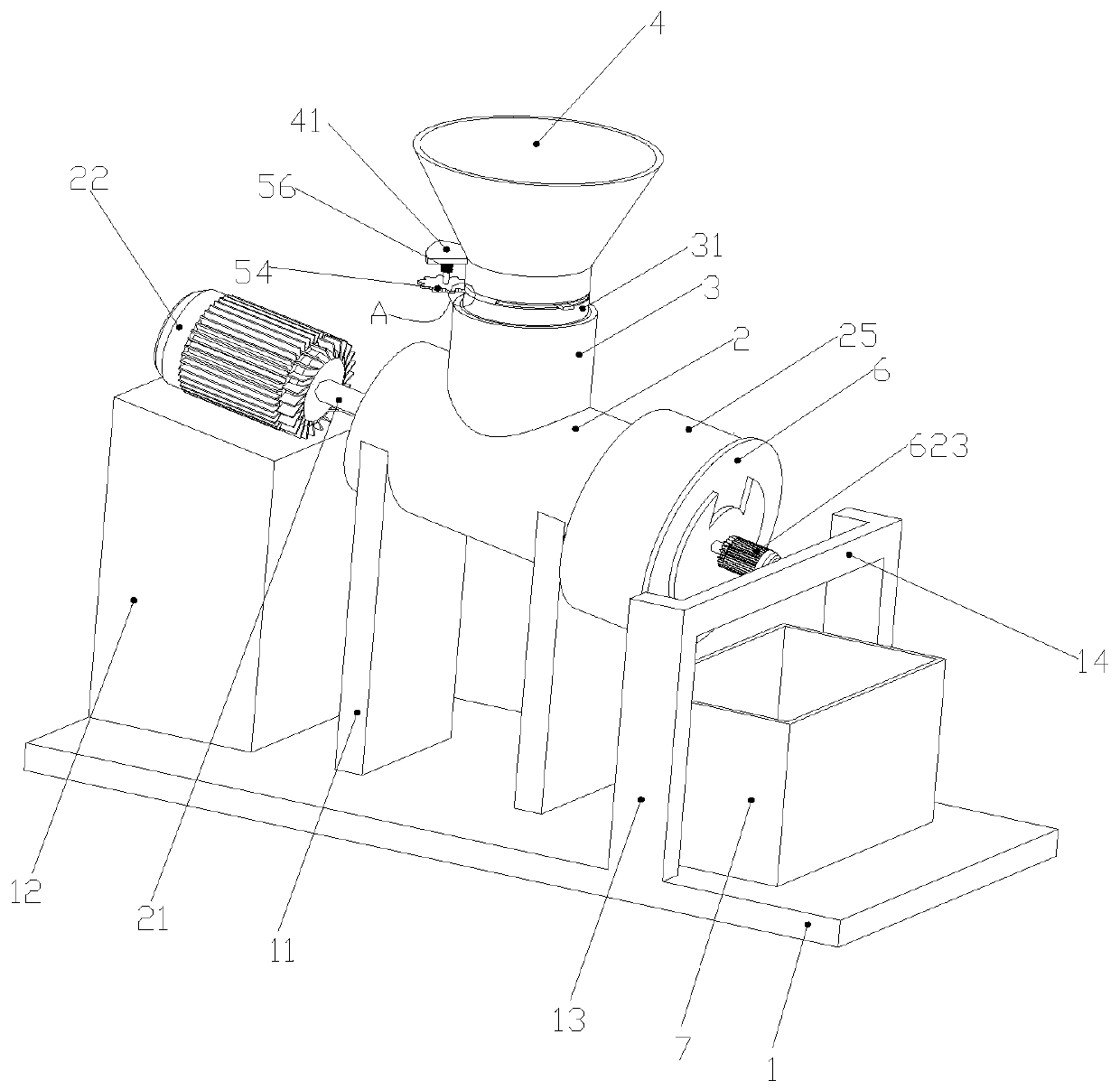

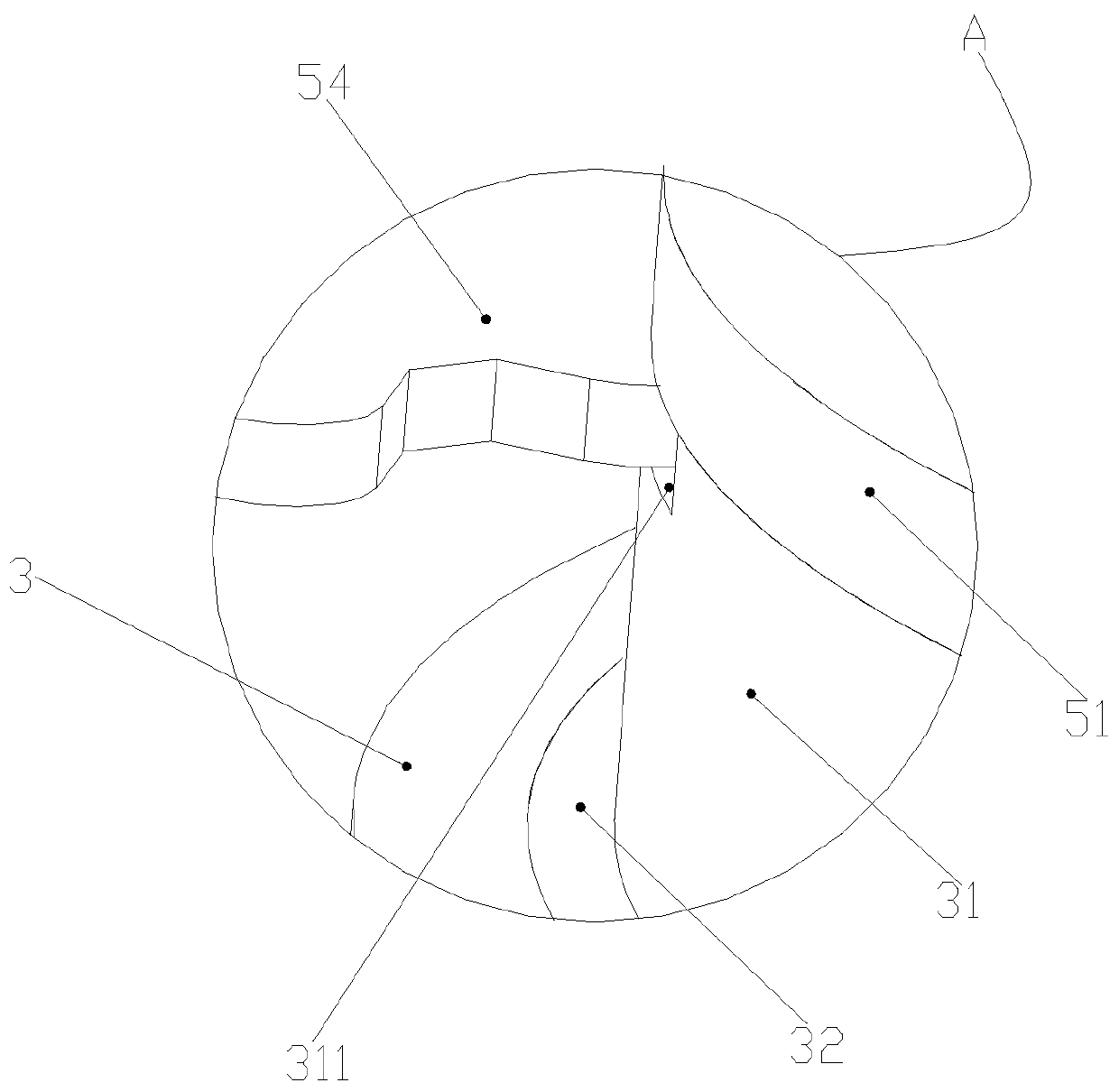

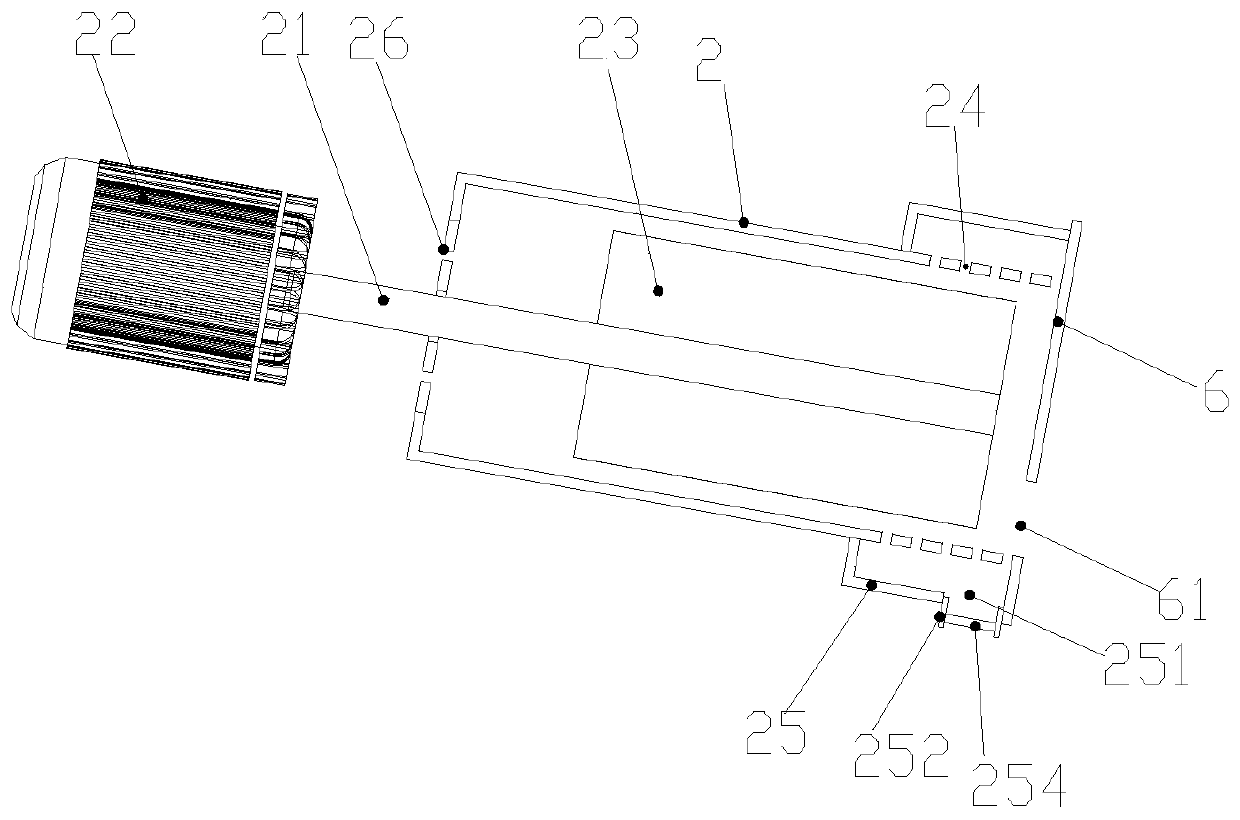

PendingCN111567638AAchieve stir fryAchieve heatingPre-extraction tea treatmentLoading/unloadingElectric machineryEngineering

The invention discloses a full-automatic continuous automatic feeding and discharging tea leaf stir-frying machine and a using method thereof. A feeding pipe is arranged at the upper end of a stir-frying cylinder; a connecting pipe is arranged in the feeding pipe; a circular feeding hopper is arranged at the upper part of the connecting pipe; a feeding control unit is arranged between the connecting pipe and the circular feeding hopper; a sealing disk is arranged at the lower end of the stir-frying cylinder; a discharging opening is formed in the sealing disk; a collecting box is arranged below the discharging opening; a sheltering plate is arranged on the outer side of the sealing disk; a material leakage opening is formed in the sheltering plate; a third rotating shaft is arranged on thesheltering plate; and the output end of a third rotating motor is tightly connected to one end of the third rotating shaft. According to the full-automatic continuous automatic feeding and discharging tea leaf stir-frying machine disclosed by the invention, according to actual requirements, the feeding control unit is adjusted to control the tea leaf quantity entering the inner part of the stir-frying cylinder one time; tea leaves in the stir-frying cylinder are stir fried, and after stir-frying of the tea leaves is completed, the sheltering plate rotates to enable the tea leaves after beingstir fried in the stir-frying cylinder to fall into the collecting box; and when the tea leaves in the stir-frying cylinder completely fall into the collecting box, the sheltering plate rotates to close the discharging opening, and then the feeding control unit is adjusted to inject tea leaves into the stir-frying cylinder for the next time.

Owner:张华

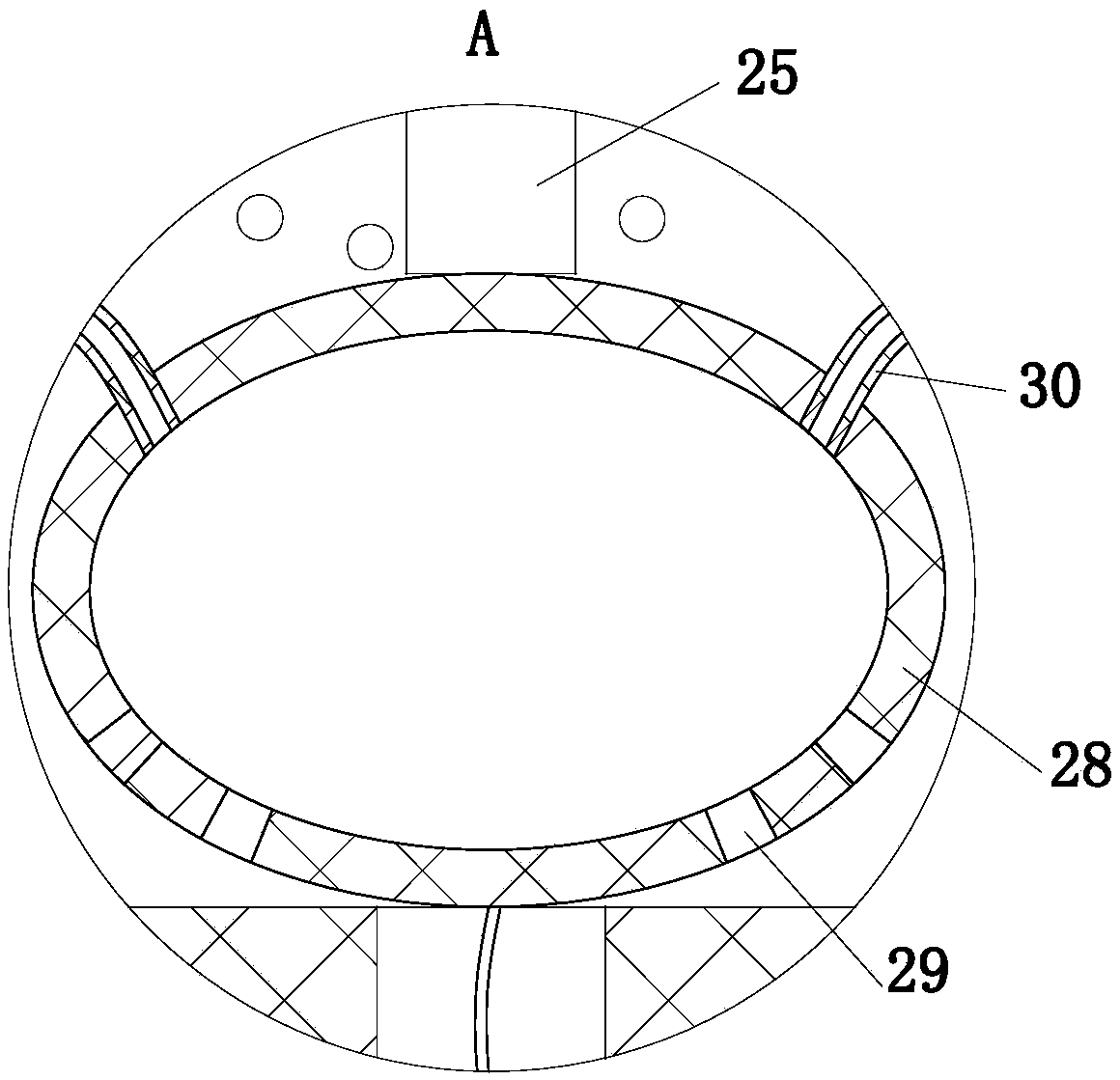

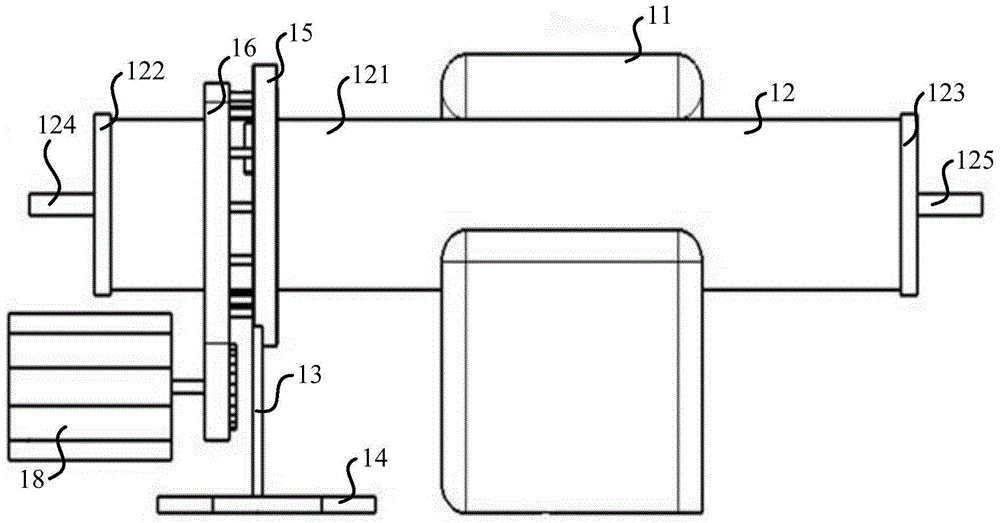

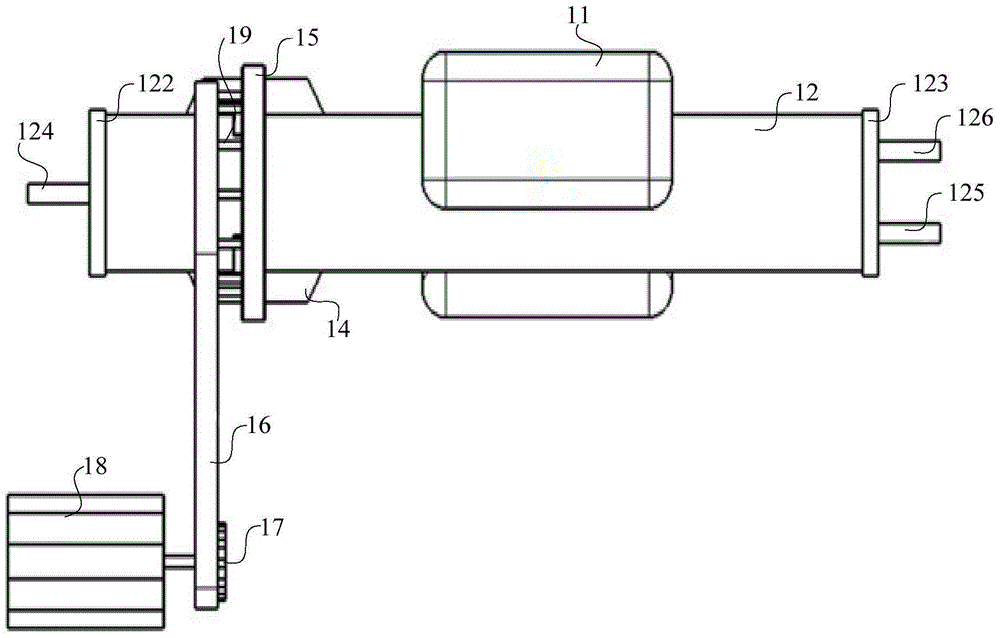

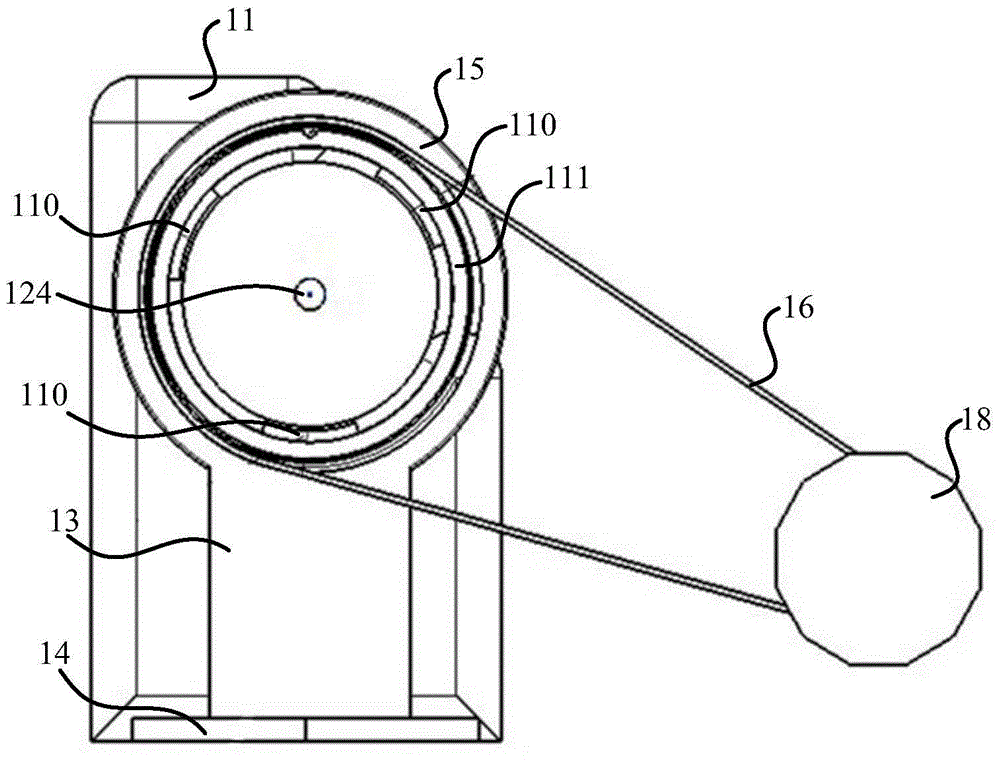

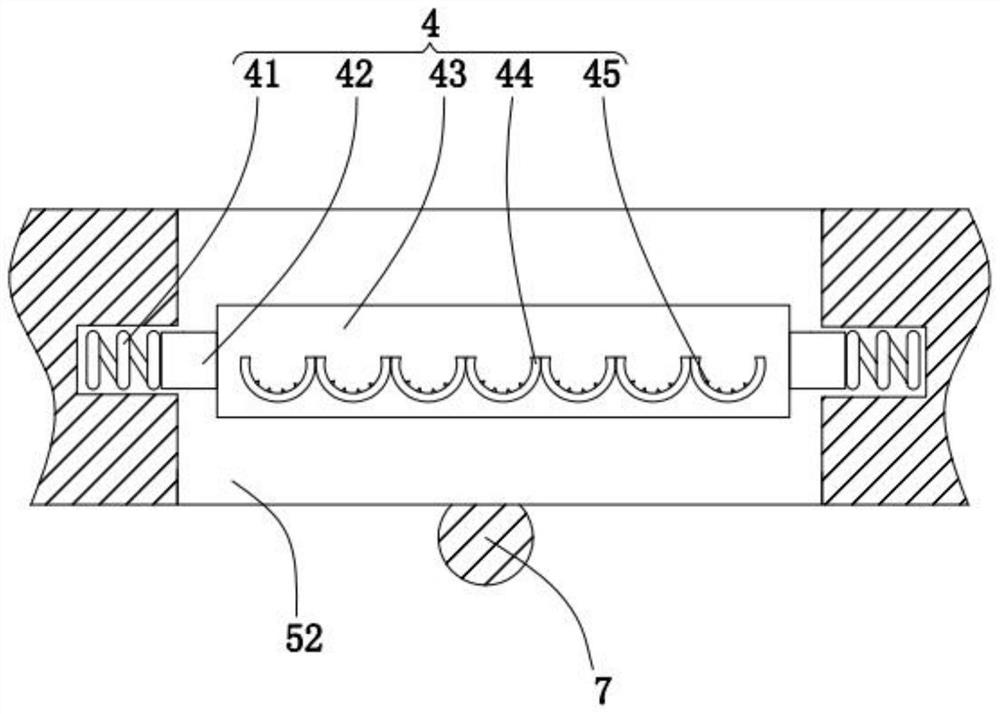

Heat treatment pipe type furnace

ActiveCN105087889ASolve problems that cannot be done in the set environmentAchieve stir fryFurnace typesHeat treatment furnacesTube furnaceEngineering

The invention provides a heat treatment pipe type furnace which comprises a heating piece, a furnace tube, a first support, a drive device, an object carrying container, second supports, a bearing, a first set of magnets and a second set of magnets. The furnace tube is connected with the heating piece. The first support is fixed to a mounting foundation and fixedly connected with an outer ring of the bearing. An inner ring of the bearing is arranged on the furnace tube in a sleeving manner, and a gap is reserved between the inner ring of the bearing and the outer wall of the furnace tube. The first set of magnets are distributed on the periphery of the inner ring. The drive device is connected with the inner ring to drive the inner ring to rotate around the furnace tube. The object carrying container is arranged in the furnace tube through the second supports. An inner cavity of the object carrying container is communicated with an inner cavity of the furnace tube. The portions, connected with the inner wall of the furnace tube, of the second supports are provided with idler wheels. The second set of magnets are connected with the second supports and distributed along the inner wall of the furnace tube in the peripheral direction. The second set of magnets and the first set of the magnets are oppositely distributed and are different in polarity. By means of the scheme, the problem that an object to be processed makes contact with the air due to stir-frying operation of an operator, thermal treatment cannot be conducted in the set environment is solved.

Owner:HARBIN INST OF TECH AT WEIHAI

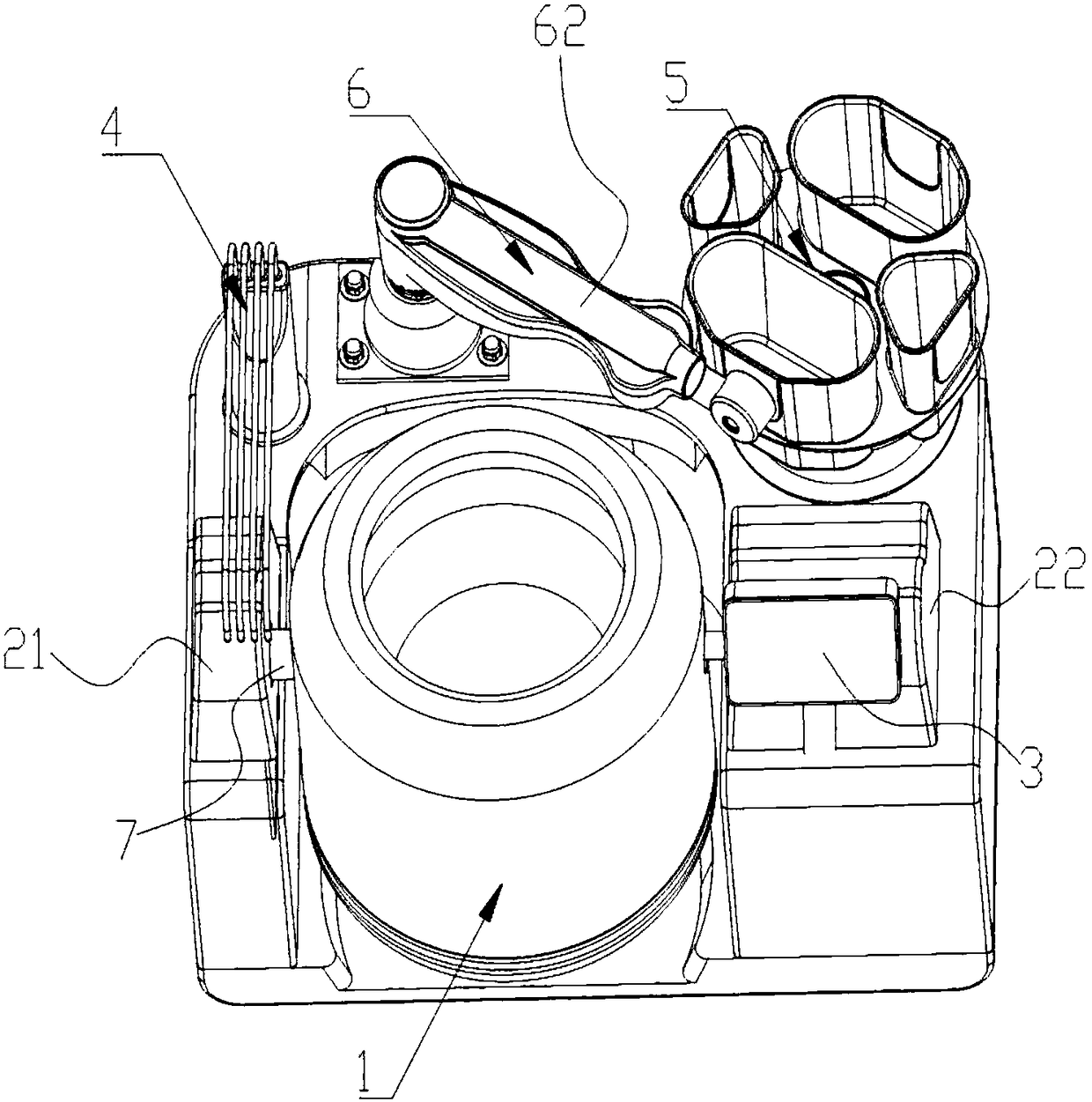

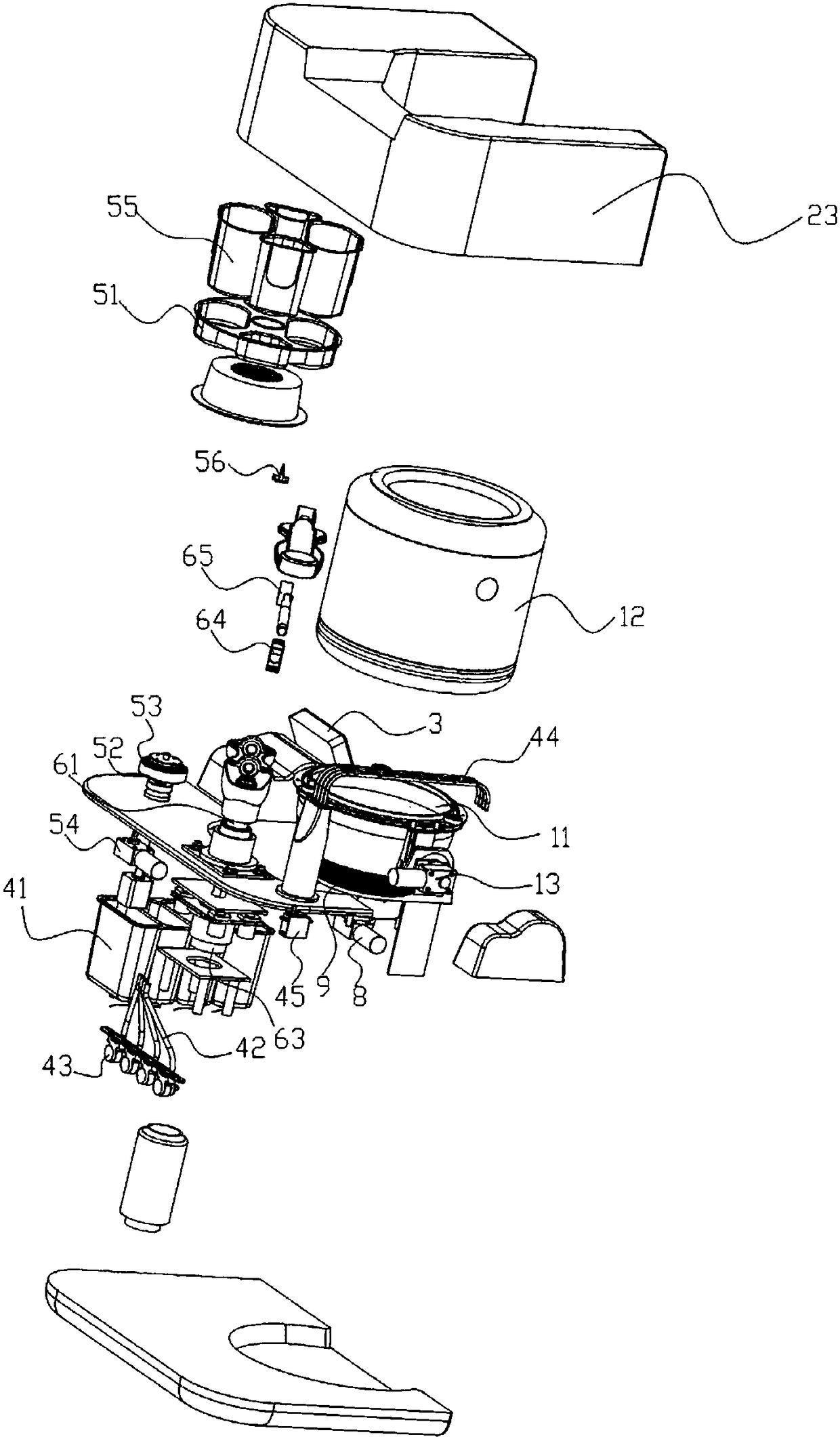

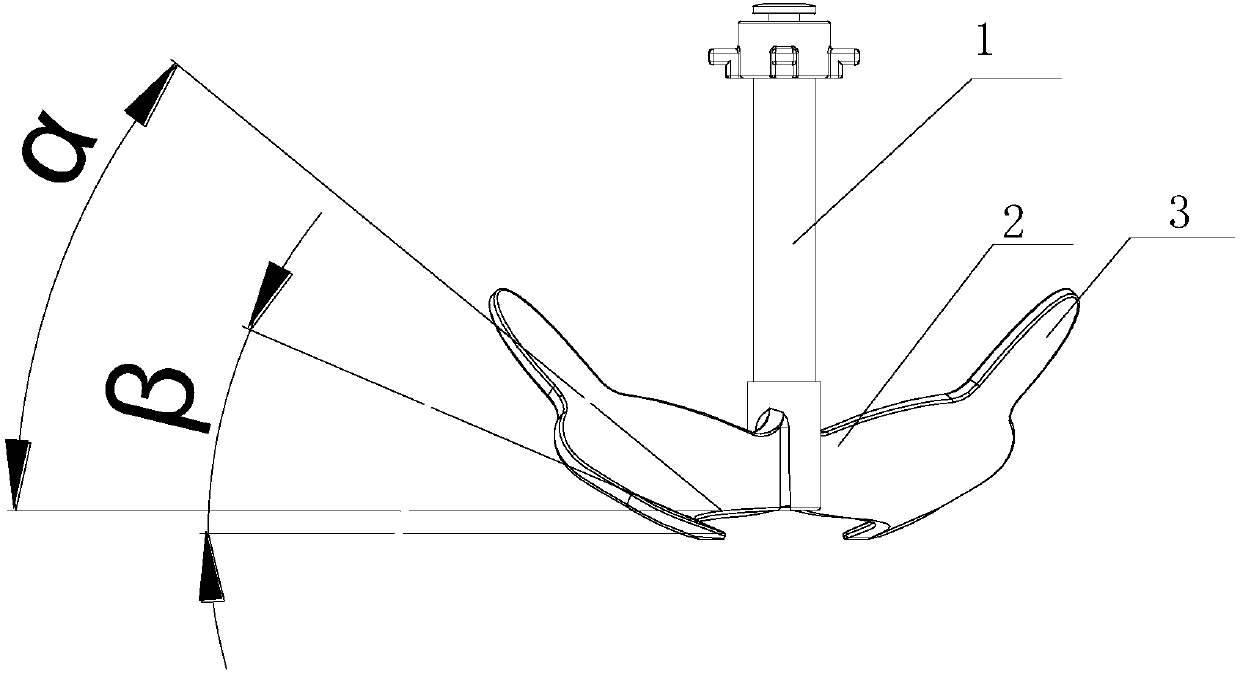

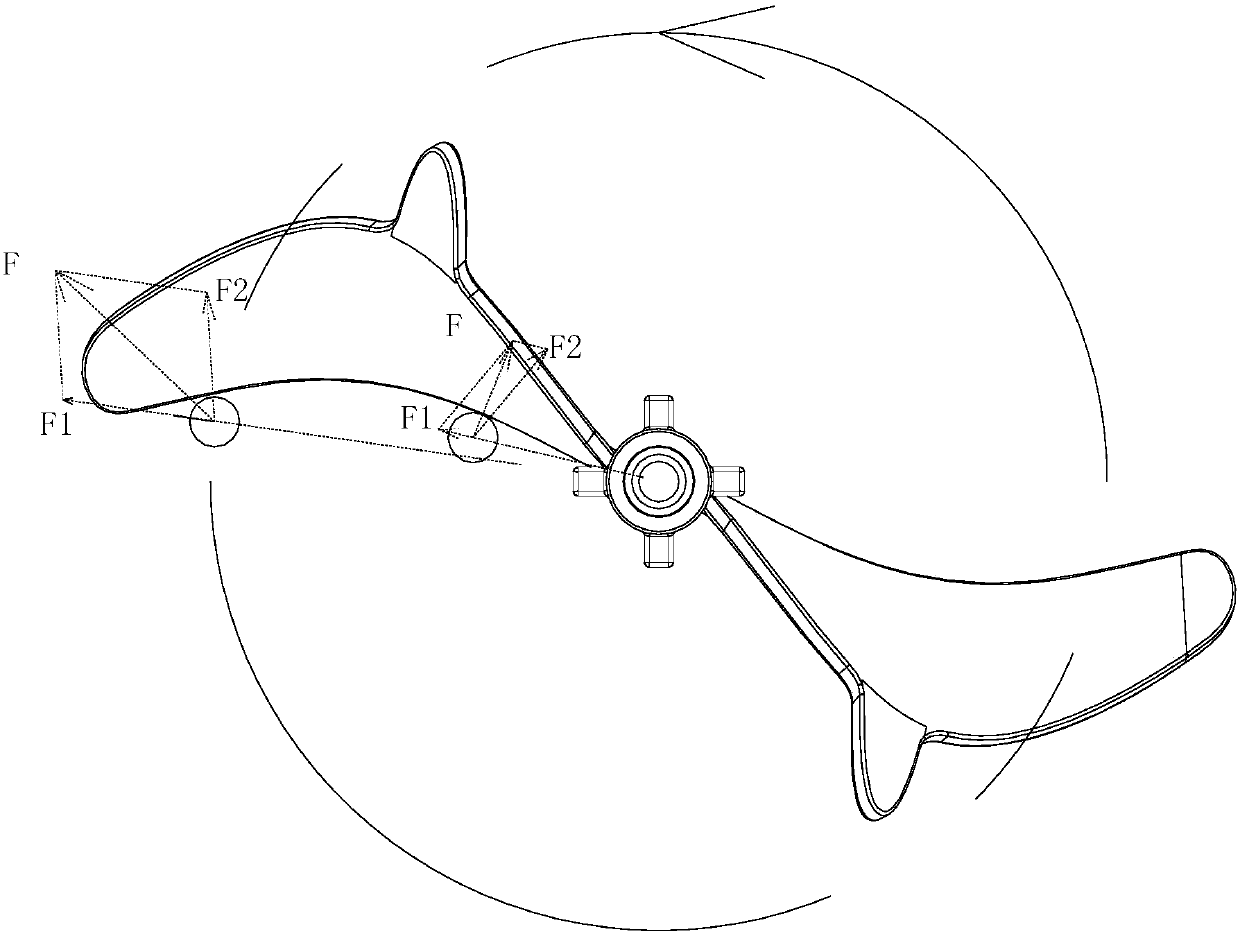

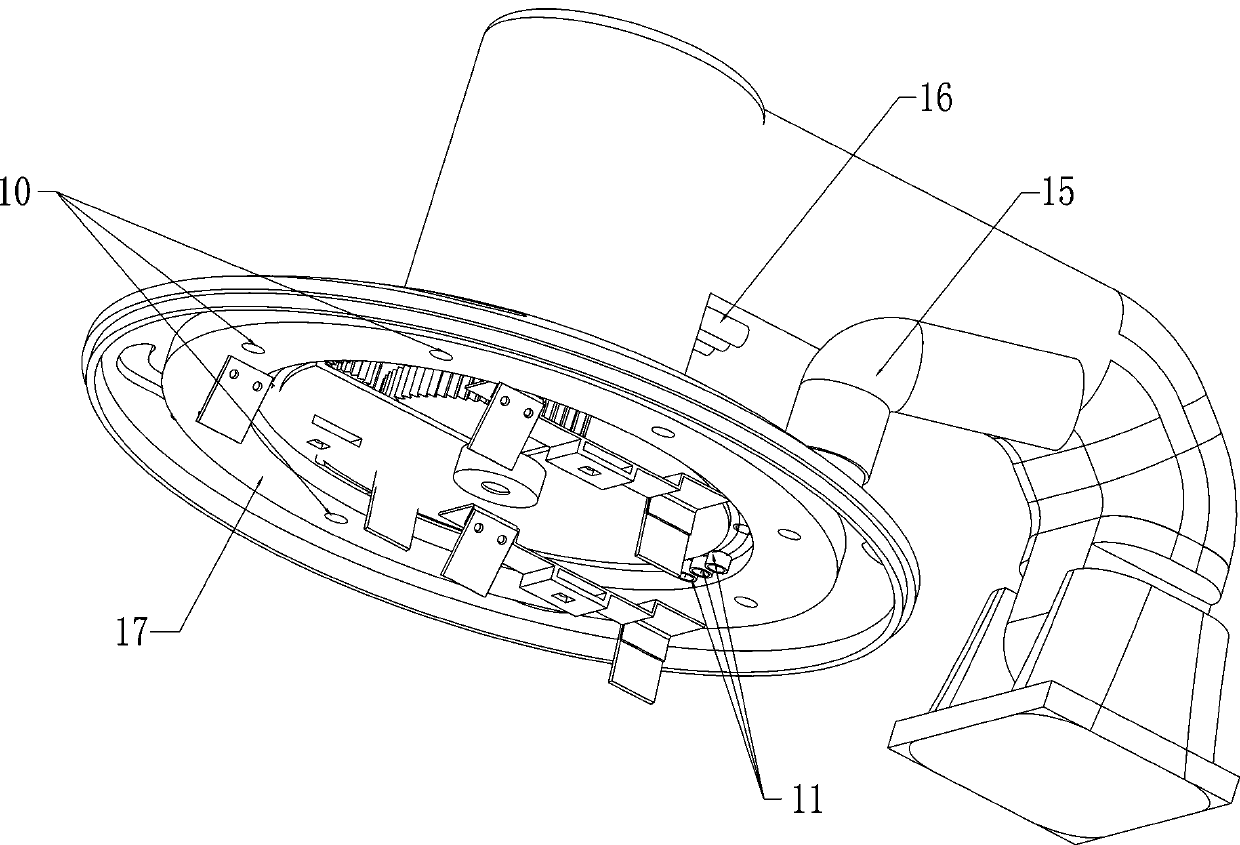

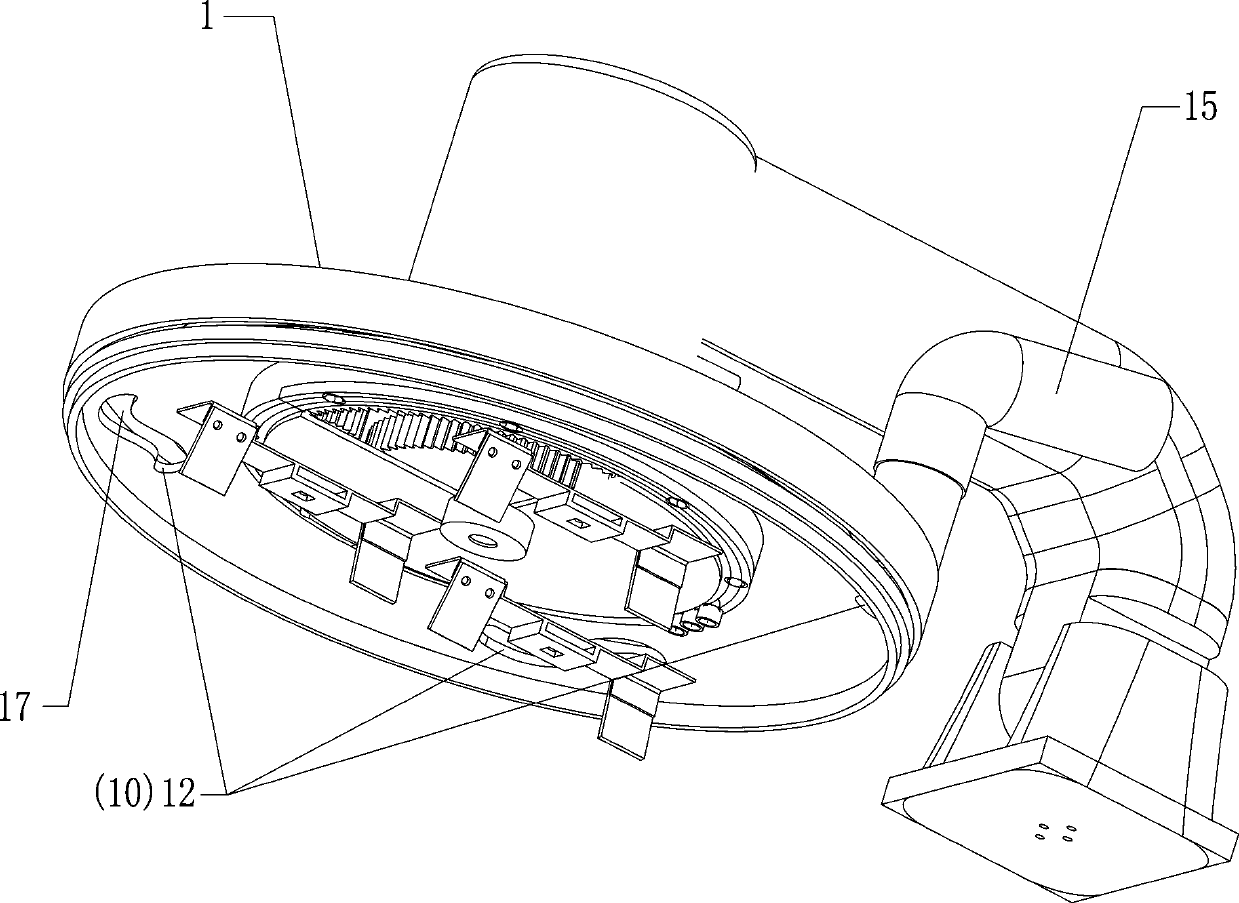

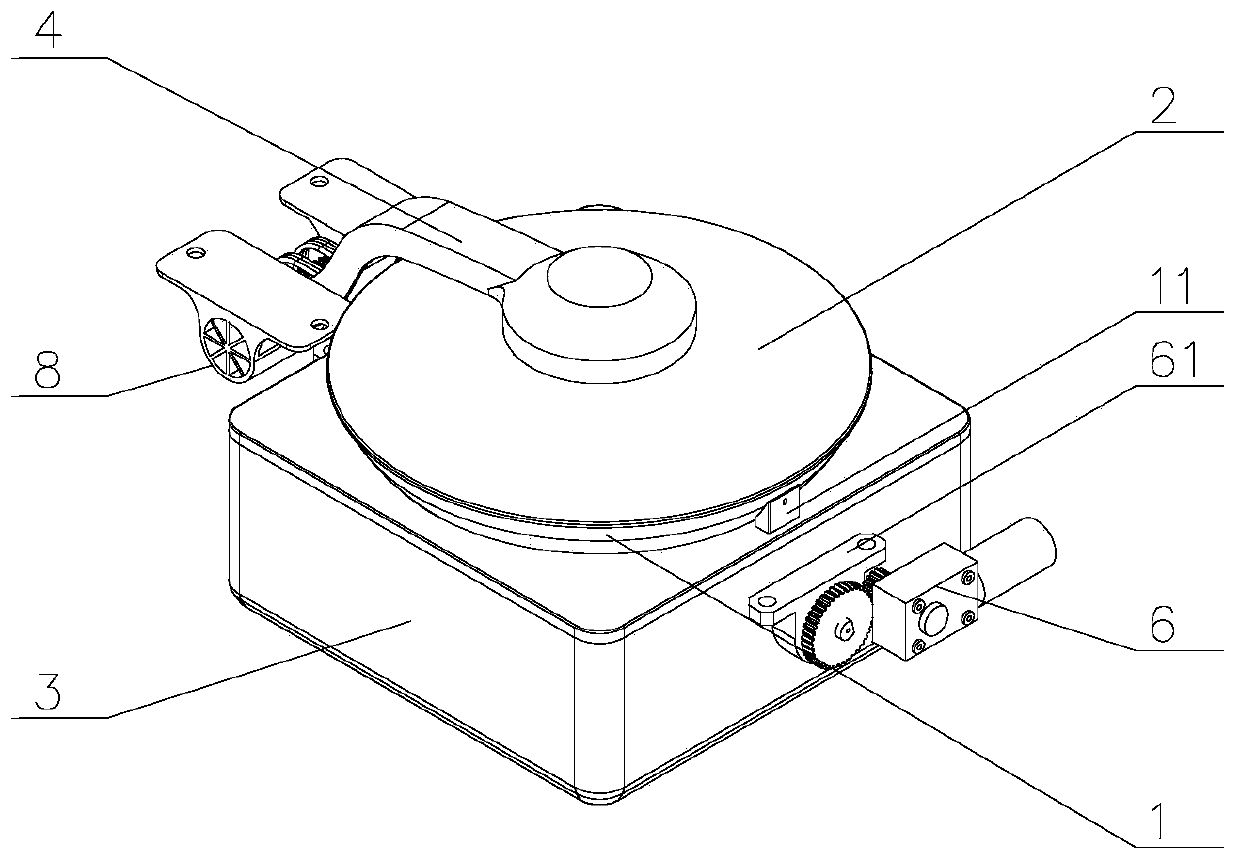

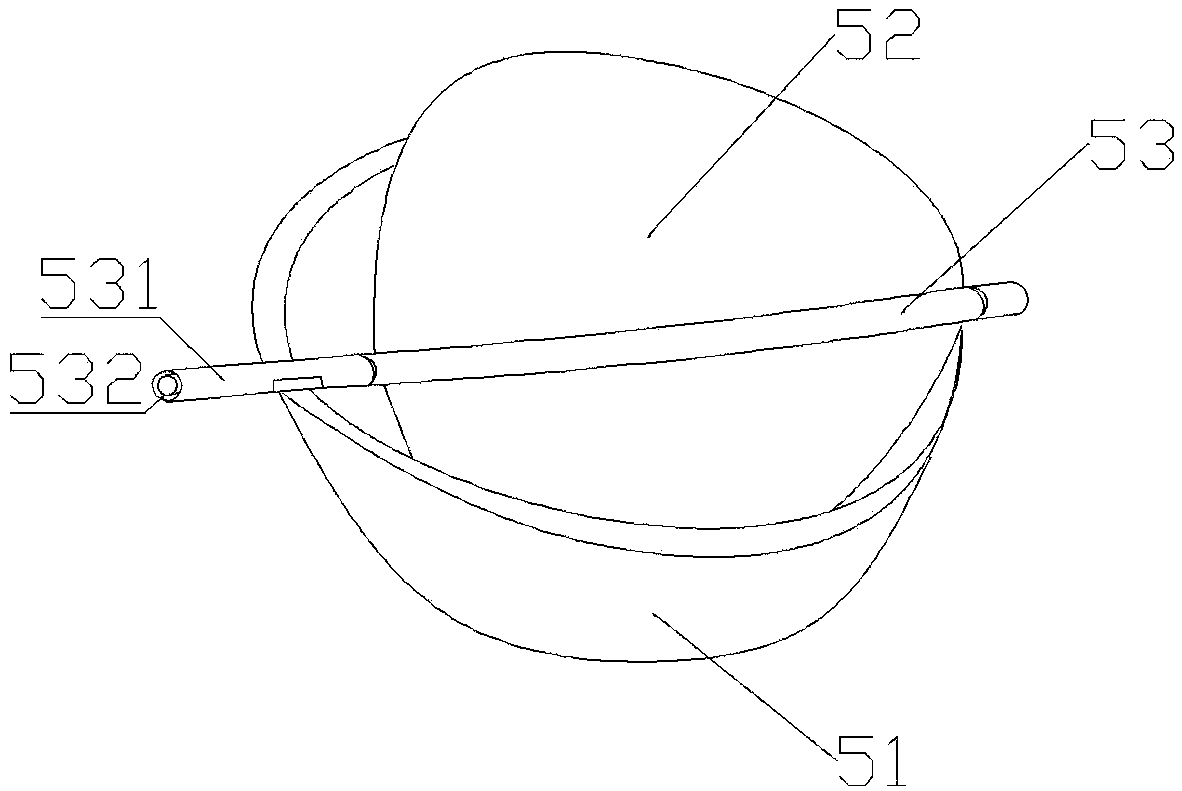

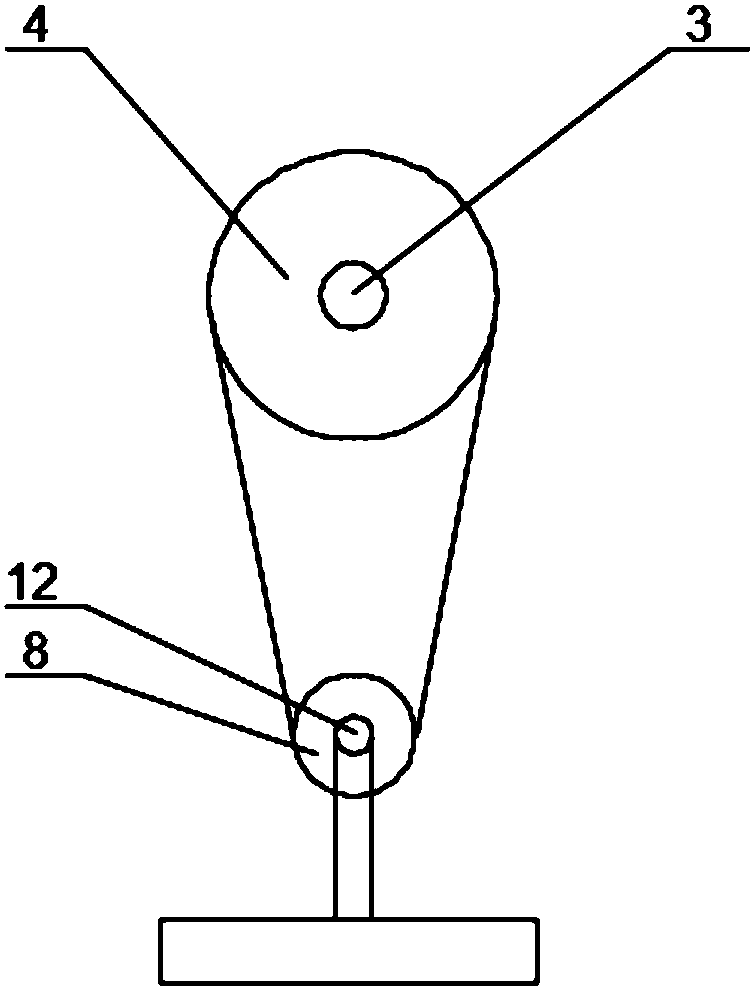

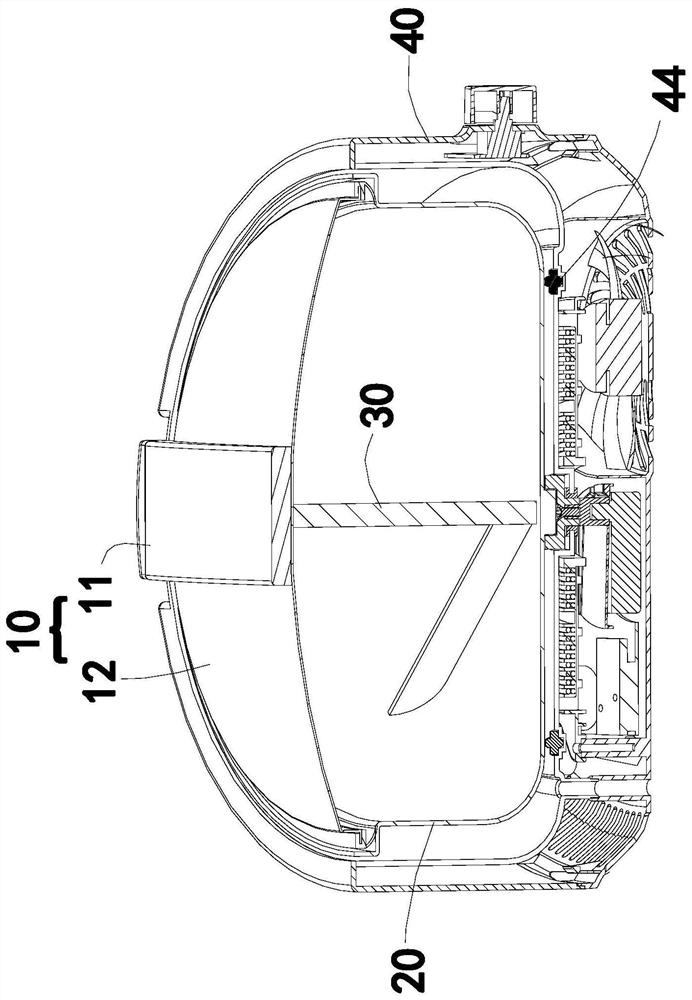

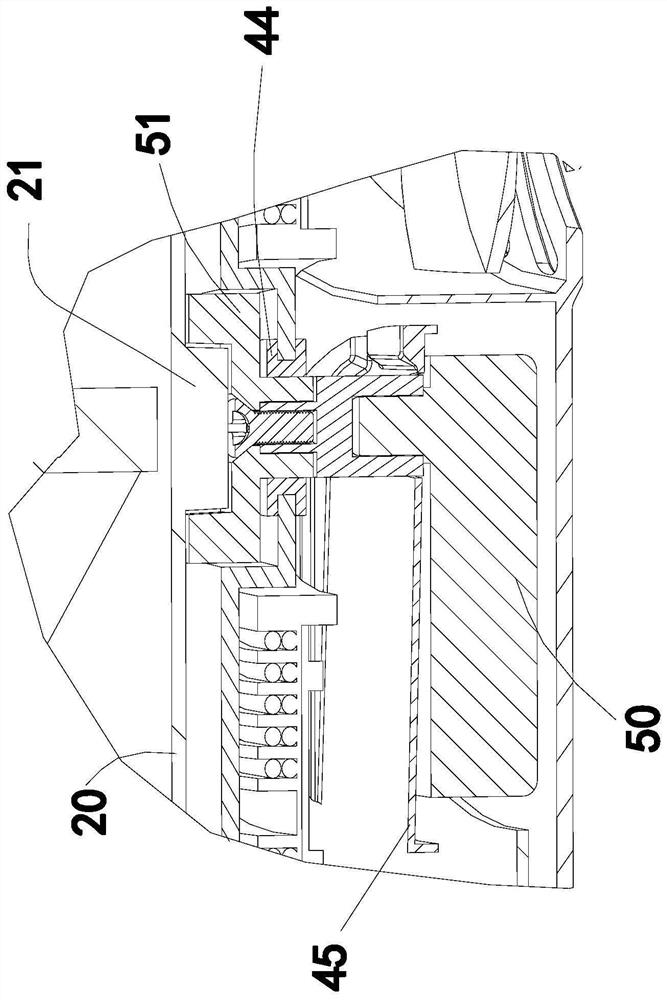

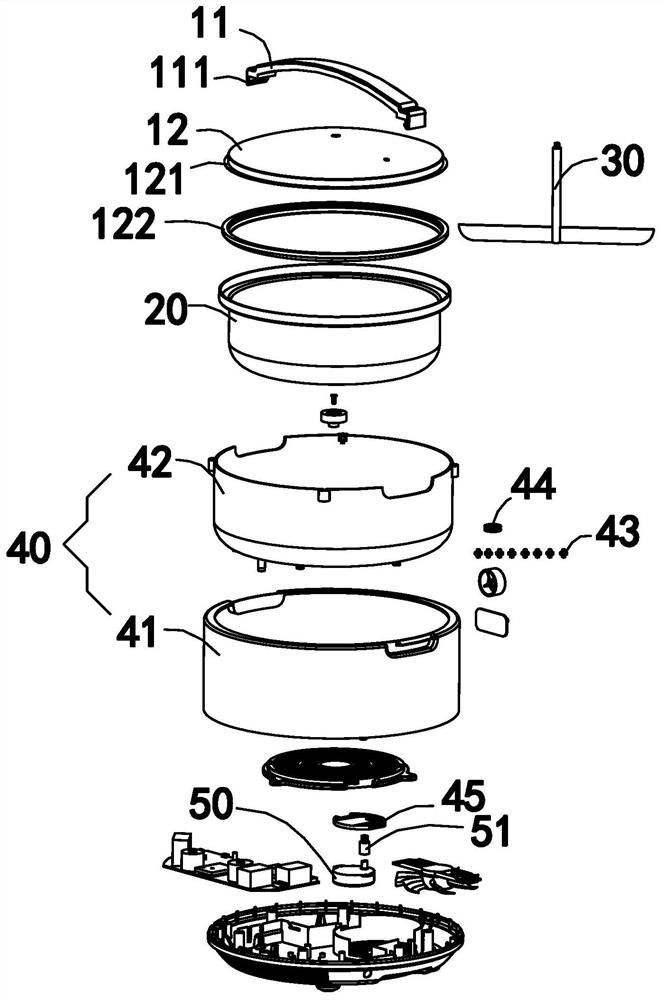

Cooking stirring rake and cooking machine provided with cooking stirring rake

ActiveCN107802184AAchieving rotary stirringRealize functionFood processingCooking insertsRotational axisEngineering

The invention relates to a cooking stirring rake and a cooking machine provided with the cooking stirring rake. The cooking stirring rake comprises a rotating shaft and stirring blades which are arranged on the rotating shaft in a mode of being close to one end of the rotating shaft; the upper end edges of the stirring blades are inclined towards the front side or back side of a rotating direction, and the lower end edges and the upper end edges of the stirring blades are in smooth curved-inclined plane transition; and an angle, which is defined by inclined planes of the ends, away from the rotating shaft, of the stirring blades and a rotating plane is less than an angle which is defined by inclined planes of the middles of the stirring blades and the rotating plane. According to the cooking stirring rake provided by the invention, since the stirring blades are arranged in a mode that the stirring blades are inclined towards the front side or back side of the rotating direction and theangle defined by inclined planes of the ends, away from the rotating shaft, of the stirring blades and the rotating plane is less than the angle defined by the inclined planes of the middles of the stirring blades and the rotating plane, functions of stirring and turning foods can be achieved in a relatively good way.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Robot for stir-frying melon seeds

InactiveCN108095154AAchieve stir fryQuick and full stir fryFood treatmentElectric machineryEngineering

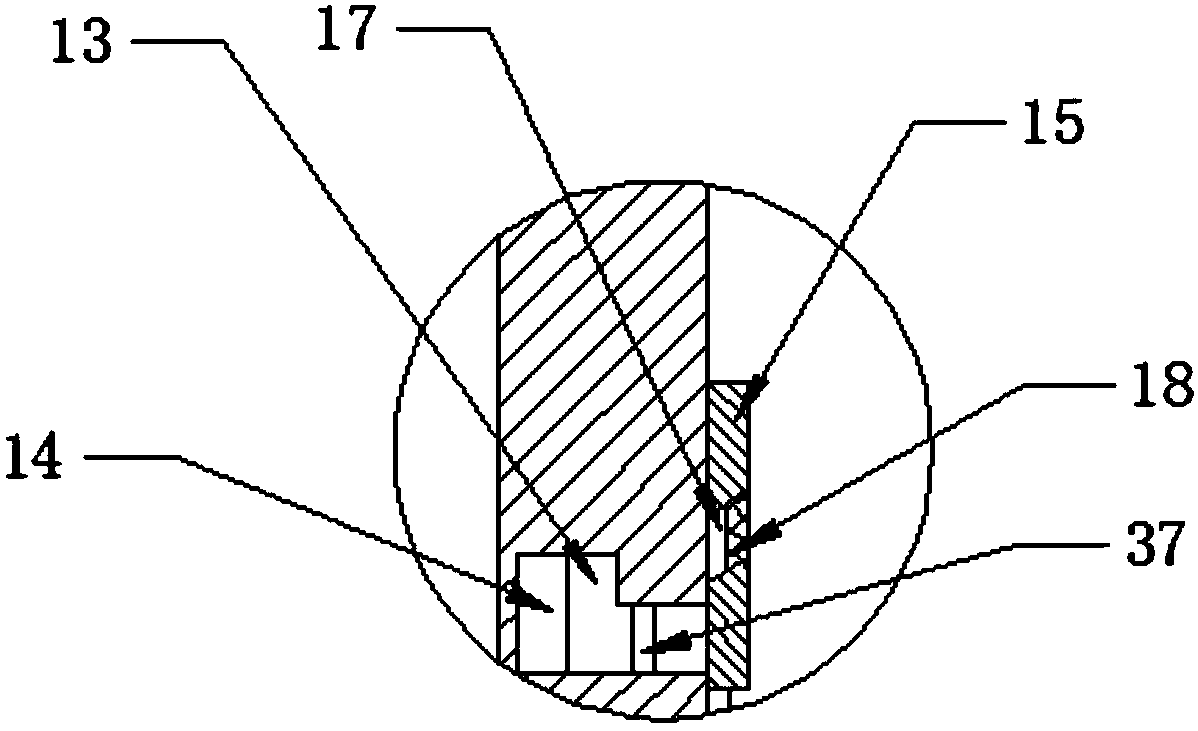

The invention discloses a robot for stir-frying melon seeds. The robot for stir-frying melon seeds comprises a bottom plate, wherein a first box body is fixedly connected to the top of the bottom plate; sliding blocks are connected to both sides of the inner wall of the first box body in a sliding manner through sliding rails; a supporting plate is fixedly connected between the opposite sides of the two sliding blocks; a second box body is fixedly connected to the top of the supporting plate; a rotating rod is rotatably connected between the top and the bottom of the inner wall of the second box body through a bearing; a cylinder is arranged on the outer surface of the rotating rod in a sleeving manner; a circular rack is arranged on the outer surface of the cylinder in a sleeving manner;and a first motor is fixedly connected to the bottom of the inner wall of the second box body and on one side of the rotating rod through a connecting block. The invention relates to the technical field of melon seed production. According to the robot for stir-frying melon seeds, rapid and thorough stir-frying in the production process of the melon seeds can be achieved, so that the workload of workers is reduced, work efficiency is improved, the melon seeds are heated more evenly in the production process through thorough stir-frying, and the mouth feel of the melon seeds is better.

Owner:湖州世韩进出口有限公司

Method for sufficiently stir-frying melon seeds

The invention discloses a method for sufficiently stir-frying melon seeds. Firstly, a worker puts the melon seeds to be processed in a cylinder through a feeding nozzle and a feeding opening, and thenoperates a control switch, so that a first motor and a second motor start to work; a vertical rod is driven to rotate by the first motor, and rotates to drive a gear to rotate; the cylinder is drivenby the gear to rotate through a round tooth belt; besides, the vertical rod drives a first belt pulley to rotate; the first belt pulley drives a second belt pulley to rotate through a belt; and the second belt pulley drives a rotating rod to rotate. Through the adoption of the method disclosed by the invention, during the production, quick and sufficient stir-frying of the melon seeds can be realized, so that the workload of the worker is alleviated, and the working efficiency is improved; and besides, the stir-frying is sufficient, so that in the production process, the melon seeds can be uniform to heat, and the mouth feel of the melon seeds is better.

Owner:潘倩韵

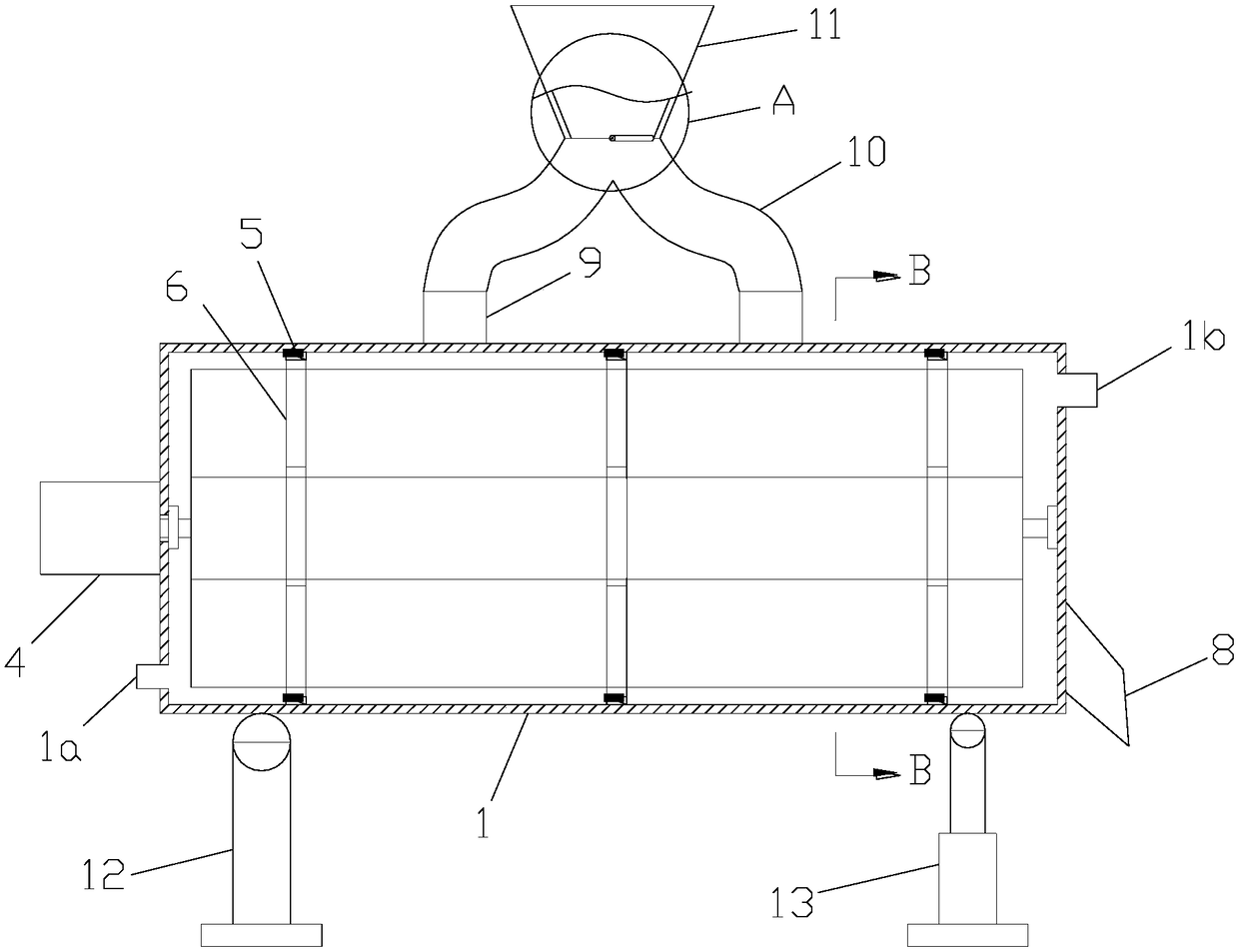

Grain drying equipment with rapid cooling function

InactiveCN108444245AReduced cooldown resurgence issuesSave time and costSeed preservation by freezing/coolingSeed preservation by dryingCold airTime condition

The invention relates to grain drying equipment with a rapid cooling function. The grain drying equipment comprises a base, supports installed on the base, a drying barrel in rotary fit with the supports through a shaft rod and a ventilation pipe installed in an inner cavity of the drying barrel and provided with a hollow structure. The top of the drying barrel is provided with a feeding hole, thebottom of the drying barrel is provided with a discharge outlet, a heating layer is integrated in the barrel wall, and a cooling water jacket is arranged outside the barrel wall. The shaft rod is provided with shaft holes. The two ends of the ventilation pipe stretch out of the shaft holes and penetrate out of the supports. The pipe wall, located in the drying barrel, of the ventilation pipe is provided with ventilation holes. Moisture in air in the drying barrel can be sucked away, external wet and cold air is prevented from entering dried air, and grains are prevented from absorbing water and regaining moisture; the grain cooling speed is increased, contact time of grains and air is effectively shortened, time conditions for production of the moisture regaining phenomenon are greatly weakened, and finally, the moisture regaining phenomenon is avoided during cooling, and the final drying quality of grains is ensured.

Owner:郑州龙威电气安装有限公司

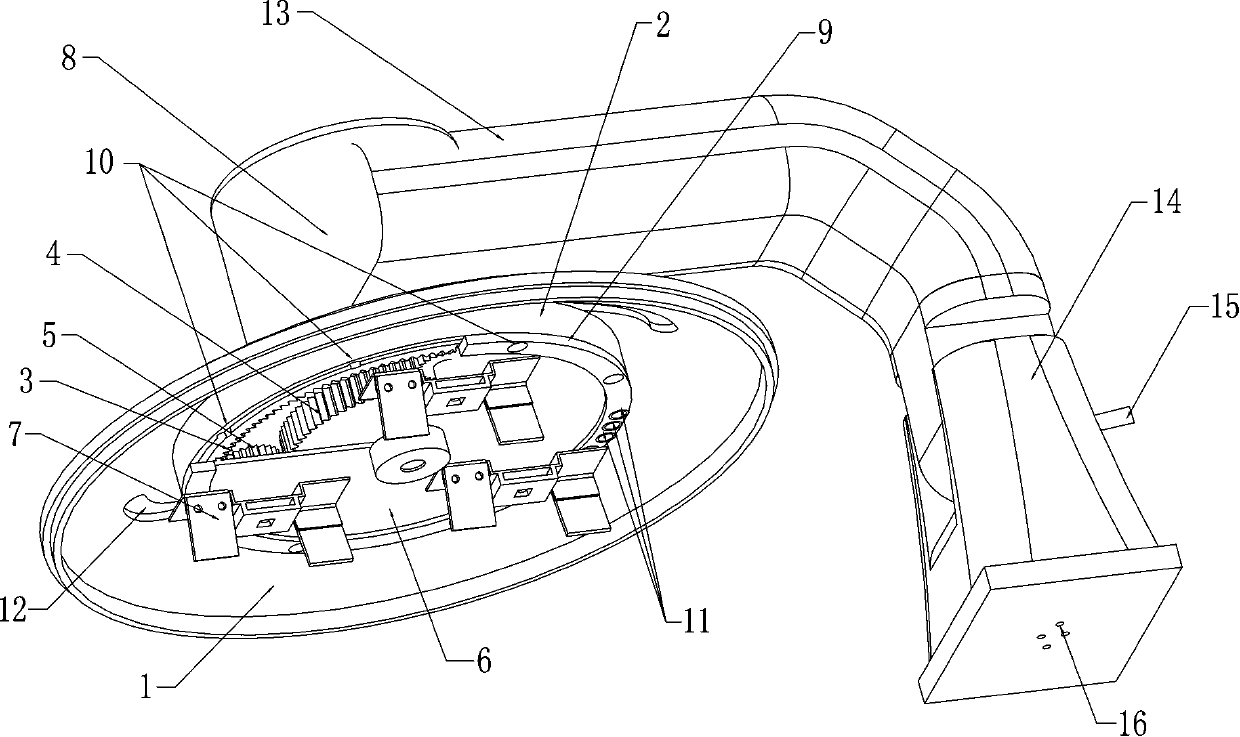

Frying pan cover

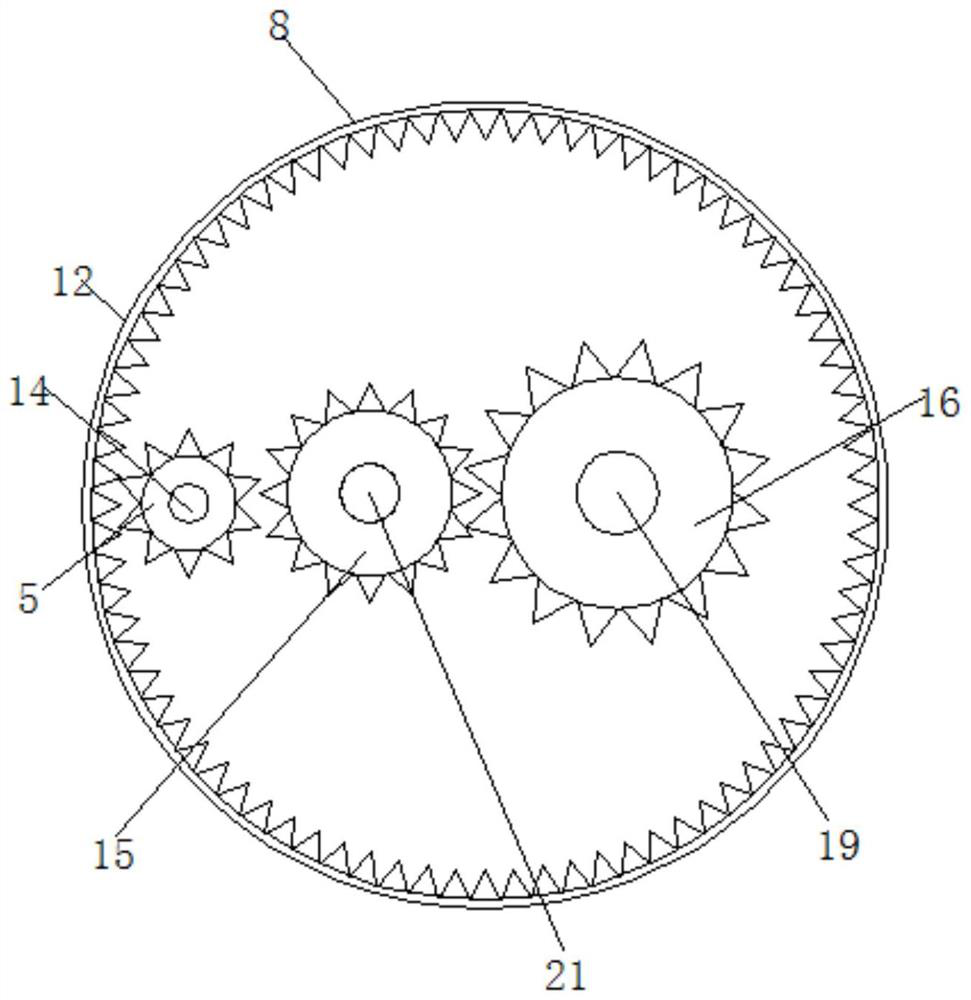

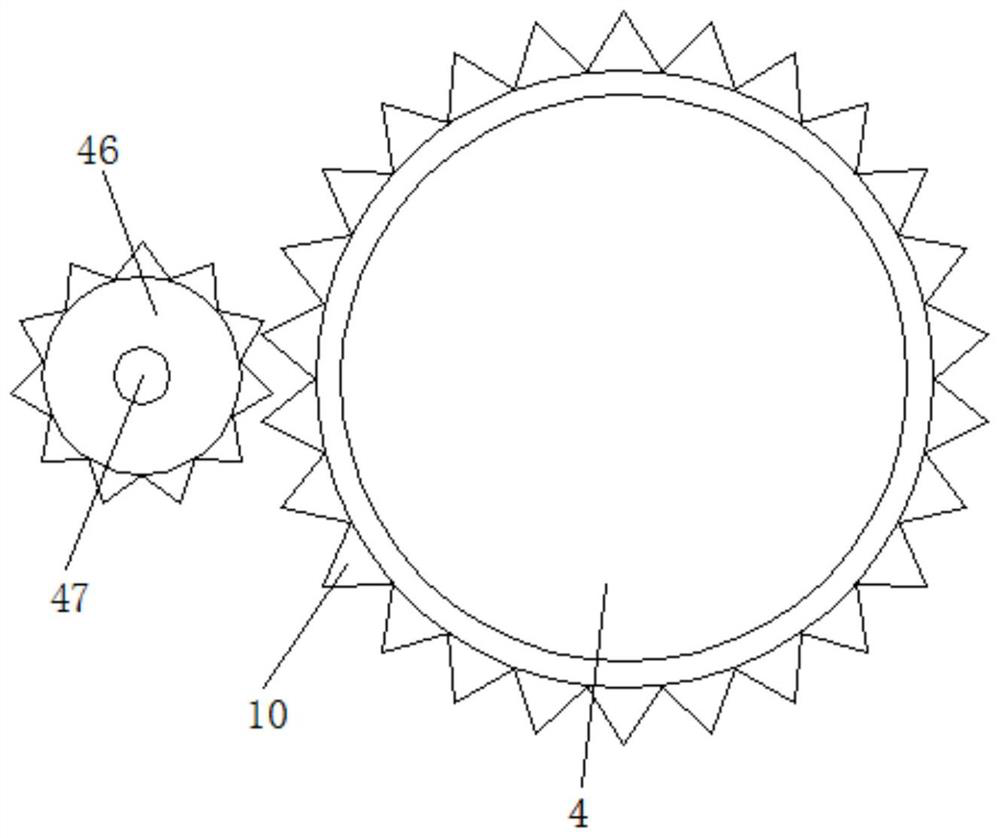

InactiveCN110742514AHidden designRange fume is effectiveDomestic stoves or rangesLighting and heating apparatusRotational axisGear drive

The invention discloses a frying pan cover which comprises a pan cover body. An installation groove is formed in the inner side of the pan cover body; circular-ring internal teeth are arranged on theinner side wall of the installation groove; a center gear, planet gears and a planet cover plate are arranged in the installation groove; the center gear and the planet gears are arranged on a rotaryshaft between the installation groove and the planet cover plate; the planet gears are meshed with the internal teeth and the center gear; rotating blades for frying penetrate through the planet coverplate through center shafts so as to be in transmission connection with the planet gears; the center gear is driven by a drive device on the outer part of the pan cover body so as to achieve autoroatation, autoroatation and revolution of the planet gears are driven afterwards, and the planet gears drive the rotating blades to rotate for frying and change a frying position in the autoroatation andrevolution process; and discharge holes and oil smoke extraction holes are formed in the inner side of the pan cover body. According to the frying pan cover provided by the invention, omni-directional stir-frying and effective oil smoke extraction are realized, and the occurrence of the phenomena of braising and overcooking is avoided.

Owner:深圳御膳坊智能科技有限公司

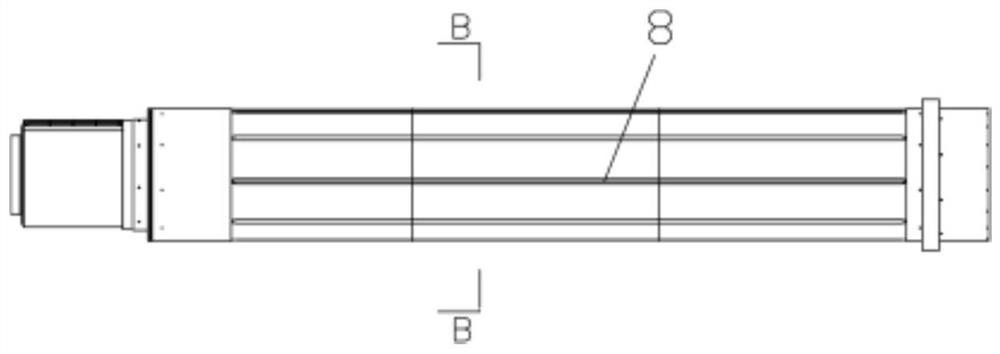

Chinese chestnut high-temperature carbide oven, Chinese chestnut peeling system and Chinese chestnut peeling technological method

PendingCN108685106AIncrease profitRealize comprehensive utilizationHuskingHullingThermal insulationEngineering

The invention relates to a Chinese chestnut high-temperature carbide oven, a Chinese chestnut peeling system and a Chinese chestnut peeling technological method. The Chinese chestnut high-temperaturecarbide oven comprises a carbide oven housing, a plurality of heating pipes for carbonizing Chinese chestnut crusts, a heat preservation and thermal insulation cylinder and a spiral transporting roller, wherein the heat preservation and thermal insulation cylinder is arranged on the outer side of the spiral transporting roller in a sleeving manner; the carbide oven housing is arranged on the outerside of the heat preservation and thermal insulation cylinder in a sleeving manner; the heat preservation and thermal insulation cylinder is fixedly connected with the carbide oven housing; the spiral transporting roller is rotatably connected with the carbide oven housing; and the heating pipes are uniformly arranged in a cavity between the thermal insulation cylinder and the spiral transportingroller in the axis direction of the spiral transporting roller. According to the Chinese chestnut high-temperature carbonized oven disclosed by the invention, the purpose that endothelium and shellsoutside Chinese chestnut kernels are carbonized and removed at a time is realized, and the thorough degree of removing is high; and besides, separation difficulty of the Chinese chestnuts and the Chinese chestnut endothelium is low, and crust carbonizing treatment can be performed on the massive Chinese chestnuts at the same time, so that the production efficiency is high.

Owner:康学全 +1

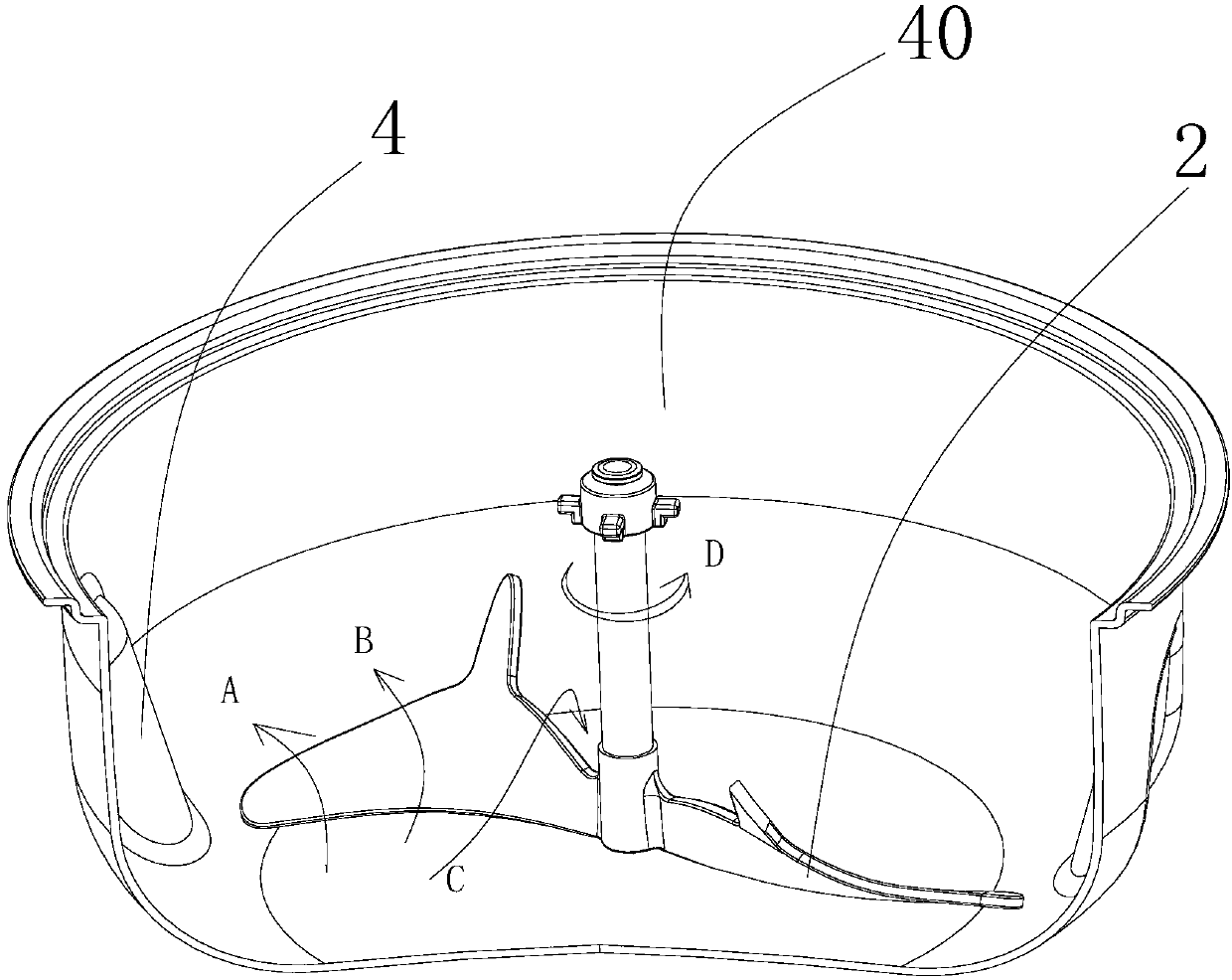

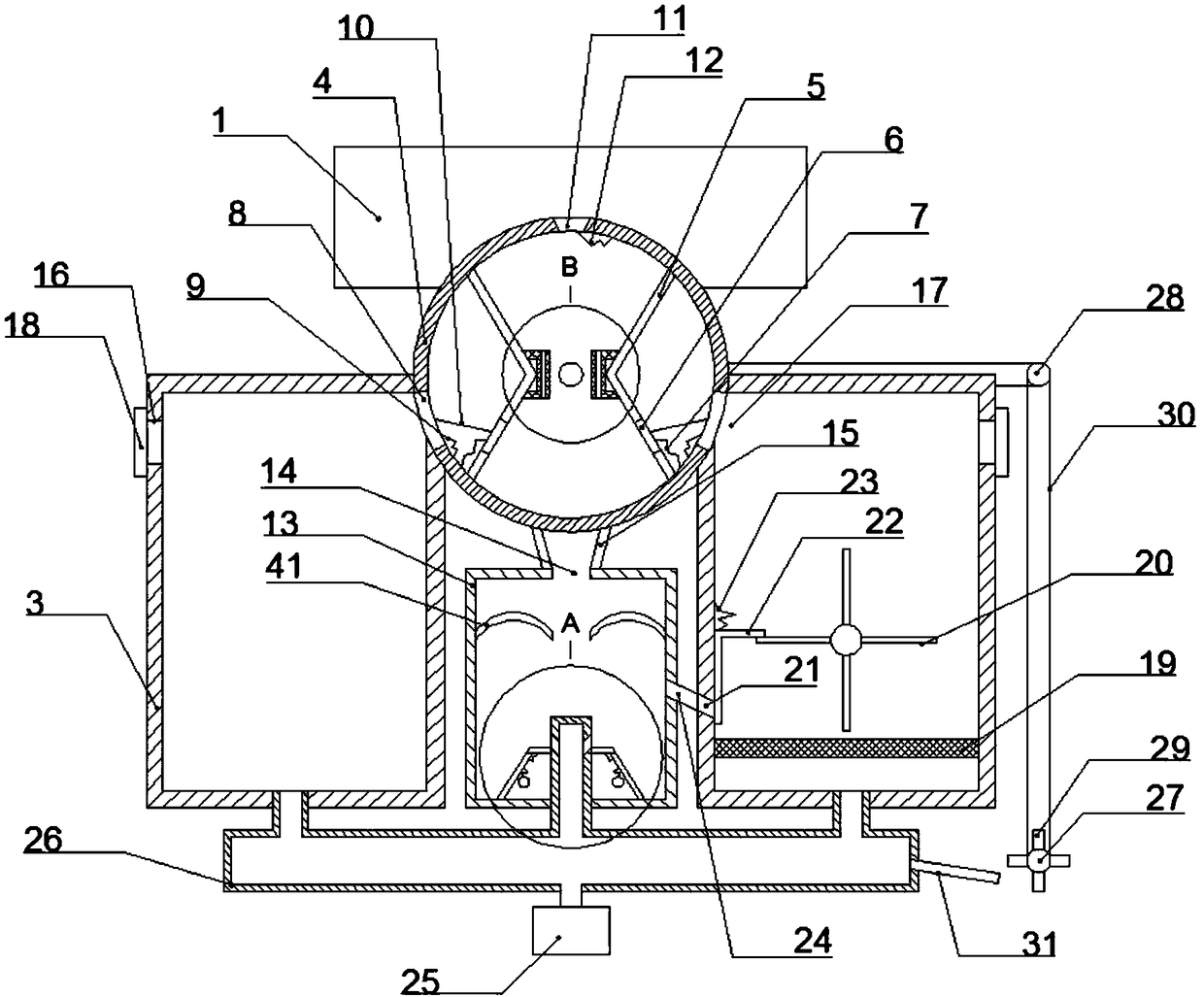

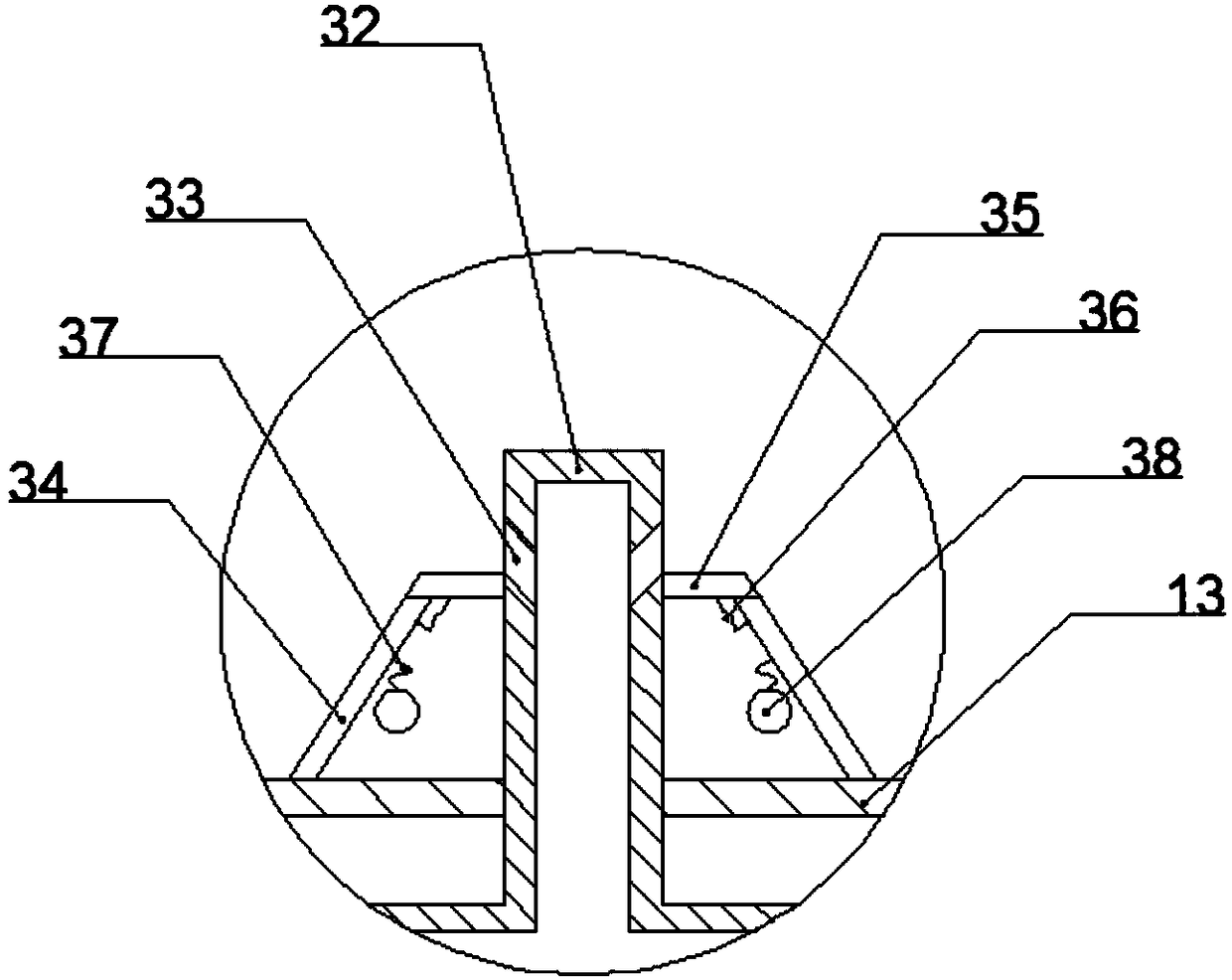

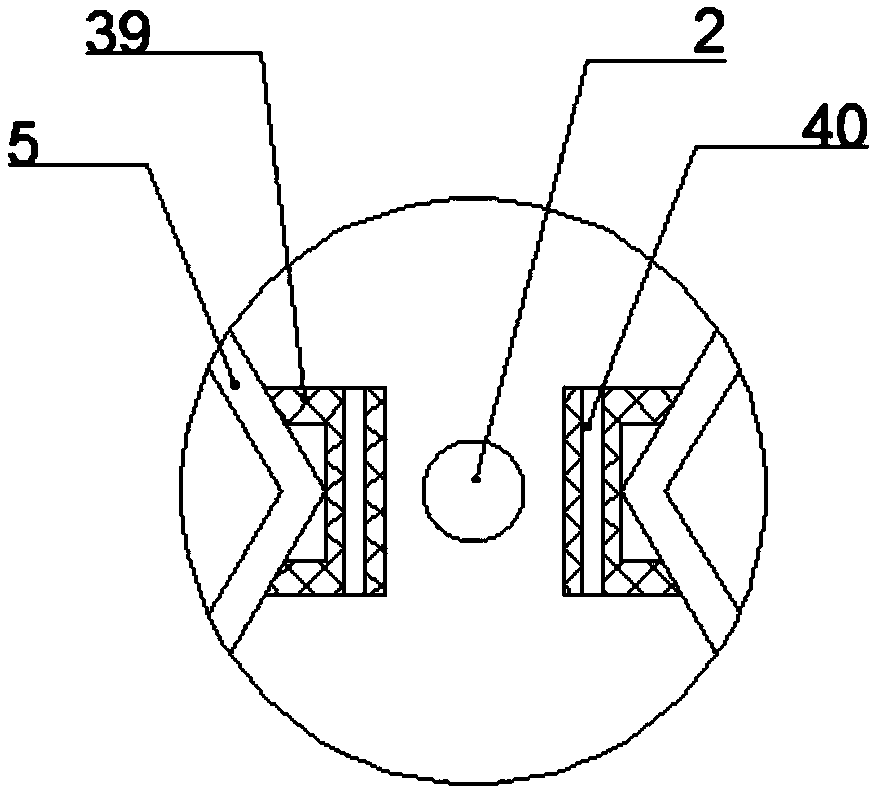

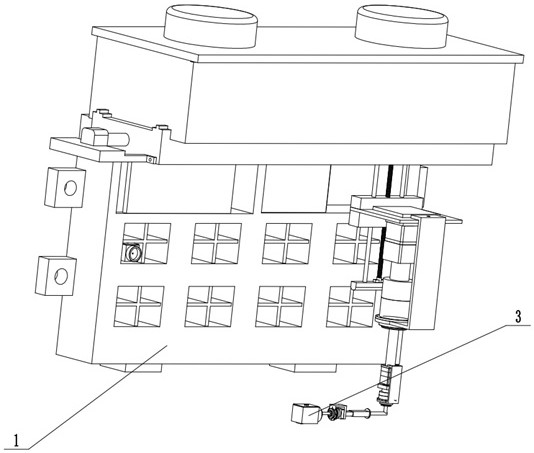

Shared automatic cooking system

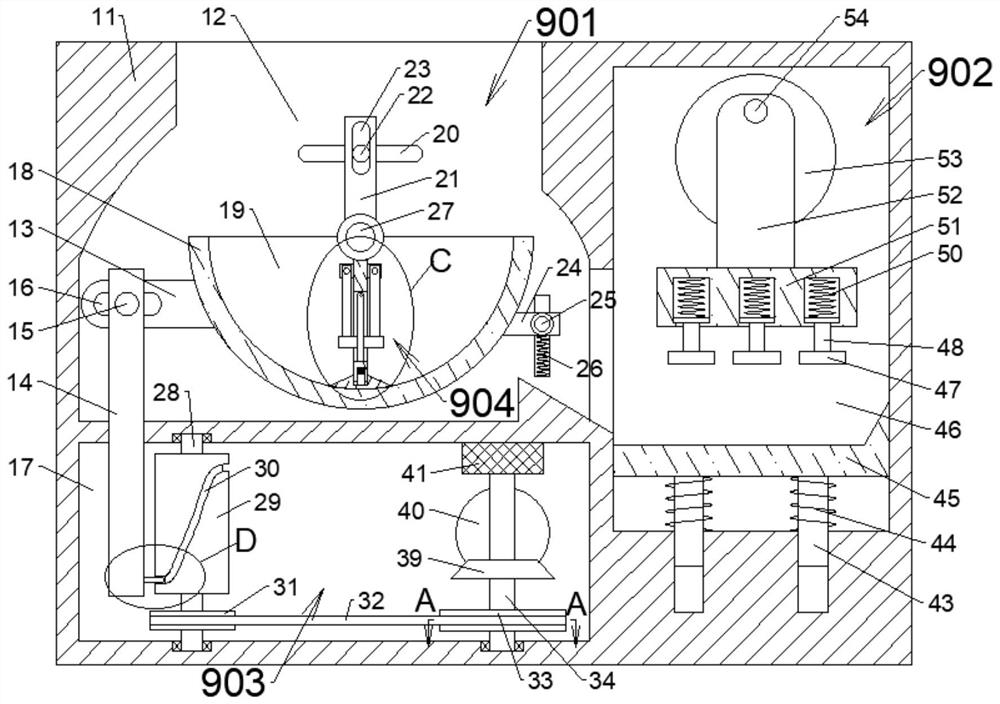

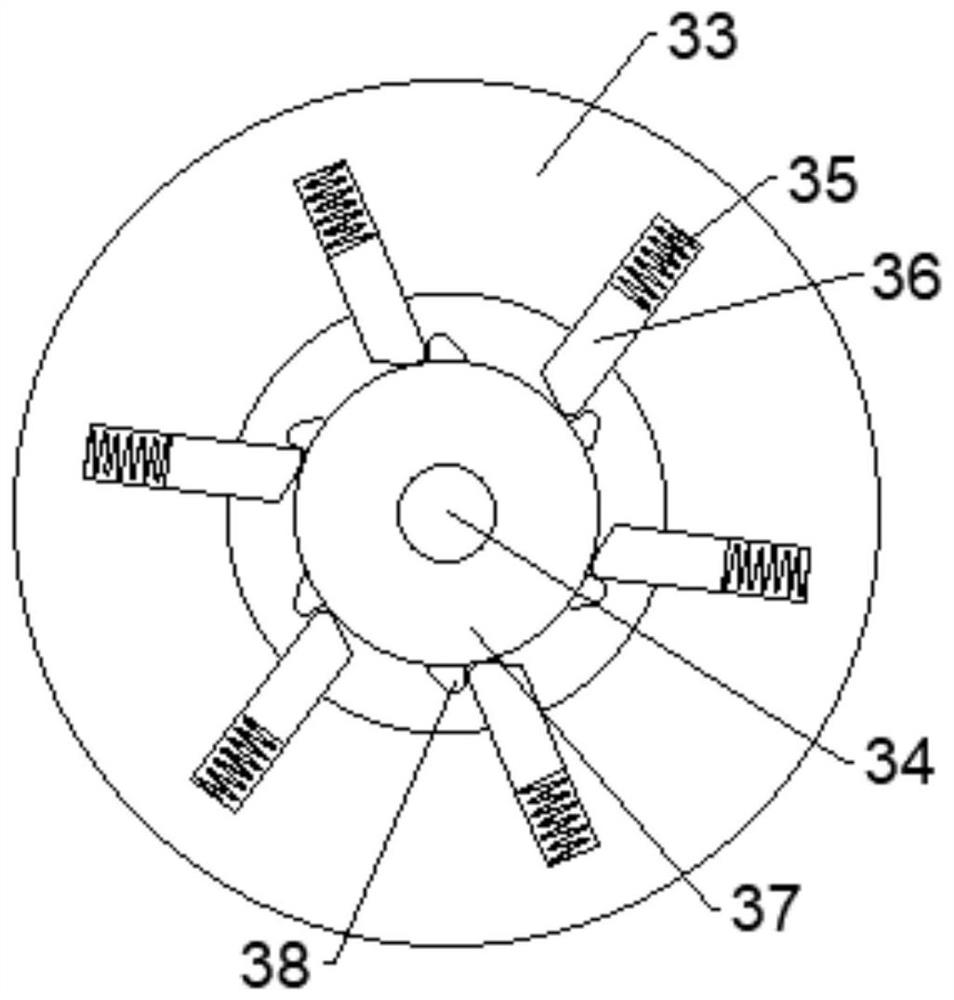

PendingCN110269504AAchieve stir fryAchieving stirringCooking-vessel lids/coversWarming devicesEngineeringBottle

The invention discloses a shared automatic cooking system, and relates to the field of automatic cooking devices. The shared automatic cooking system comprises a pot body and a pot cover arranged on the upper part of the pot body and matched with the pot body, the pot body comprises an electromagnetic furnace which is integrally packaged with the pot body, and further comprises a driving device A for driving the electromagnetic furnace to rotate along an axis parallel to the horizontal plane; the pot cover comprises a pot cover handle connected to the pot cover and a pot shovel assembly arranged on the inner side surface of the pot cover, further comprises a driving device B for driving the pot shovel assembly to rotate along the middle axis of the pot cover, and a driving device C for driving the pot cover to rotate along an axis parallel to the horizontal plane is further included. According to the share-based automatic cooking system, through turnover of the pot body, rotation of the pot shovel and arrangement of a material bottle connecting pipe, a series of automatic cooking processes such as stir frying, seasoning and dish up of dishes are achieved, and the problem that the automation degree of existing automatic cooking equipment is low is solved.

Owner:杭州板牙科技有限公司

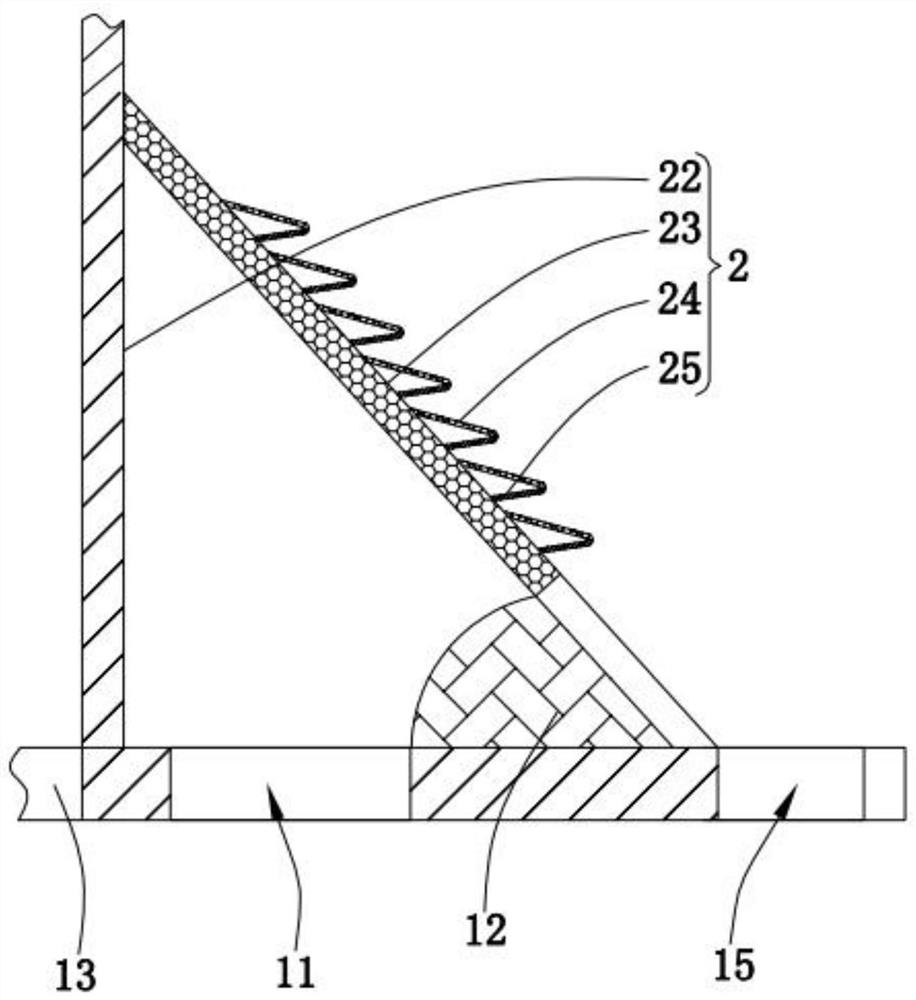

Fixation device for tea leaves

InactiveCN107348029AAchieve stir fryFinish evenlyPre-extraction tea treatmentEngineeringLinkage concept

The invention discloses a fixation device for tea leaves. The fixation device comprises a box, wherein a processing groove is formed in the box, the inner wall of the processing groove is rotationally connected with a support shaft, and a rotatable gear is fixedly connected onto the support shaft; a driving mechanism for driving the support shaft to rotate intermittently is arranged on the inner wall of the processing groove; a first rack and a second rack which can be meshed with the rotatable gear are arranged on the rotatable gear in an upper-lower manner, and a linkage mechanism for fixing tea is arranged on each of the first rack and the second rack. The device mainly solves the problems that an existing fixation machine for tea leaves cannot heat and stir-fry tea leaves uniformly.

Owner:GUIZHOU PROVINCE ZHENGAN COUNTY YIREN TEA IND CO LTD

Rana nigromaculata meat processing device

ActiveCN110583960ARealize the undertakingAchieving stirringFood processingDrying machines with non-progressive movementsRana nigromaculataEngineering

The invention discloses a rana nigromaculata meat processing device. The rana nigromaculata meat processing device comprises a machine base and a rotating roller arranged on the machine base, whereinthe rotating roller is provided with an opening in one side, a feeding pipe which is used for transporting rana nigromaculata meat is arranged inwards in the opening, and an outlet of the feeding pipefaces the downward rotation side of the rotating roller; sliding grooves are uniformly formed in the outer wall of the rotating roller in a spaced manner; a moving plate is arranged in each sliding groove; a plate outlet allowing each moving plate to pass is formed in a position corresponding to the corresponding moving plate, on the inner wall of the rotating roller; and a rolling roller is arranged above the bottom in the rotating roller. According to the rana nigromaculata meat processing device disclosed by the invention, steamed rana nigromaculata meat can be continuously subjected to drying and stir-frying processing; in the overturning and rolling process, the steamed rana nigromaculata meat can be quickly dried and stir-fried; and besides, the moving plates which can be automatically expanded and contracted are used for cooperation for overturning and stirring, the whole process is efficient and intelligent, and the operation is simple, convenient and reliable.

Owner:HUNAN BIOLOGICAL & ELECTROMECHANICAL POLYTECHNIC

Drying device for tea production

InactiveCN113310301AAchieve rotationAchieve dryingPre-extraction tea treatmentTea dryingAgricultural engineeringElectric machinery

The invention discloses a drying device for tea production, which comprises a supporting plate; the right end of the supporting plate is fixedly connected with a collecting box; the right end of the collecting box is fixedly connected with a connecting rod; the top end of the connecting rod is fixedly connected with a first fixed frame; the part, close to the left side, of the top of the supporting plate is fixedly connected with a second fixed frame; the top ends of the first fixed frame and the second fixed frame are jointly connected with a fixed plate; the top end of the fixed plate is fixedly connected with a motor; a circular bearing is arranged below the fixing plate; and the left end and the right end of the circular bearing are fixedly connected to the side walls of the first fixed frame and the second fixed frame. According to the drying device for the tea production provided by the invention, a worm, a worm gear, a moving rod, a third sliding block, a transverse block, a hot air box and an air spraying pipe are used in cooperation, so that tea leaves can be dried in a reciprocating mode, and the situation that the tea at one place is dried for a long time, drying is uneven, the tea leaves are burnt, and tea leaf waste is caused is avoided.

Owner:温延娟

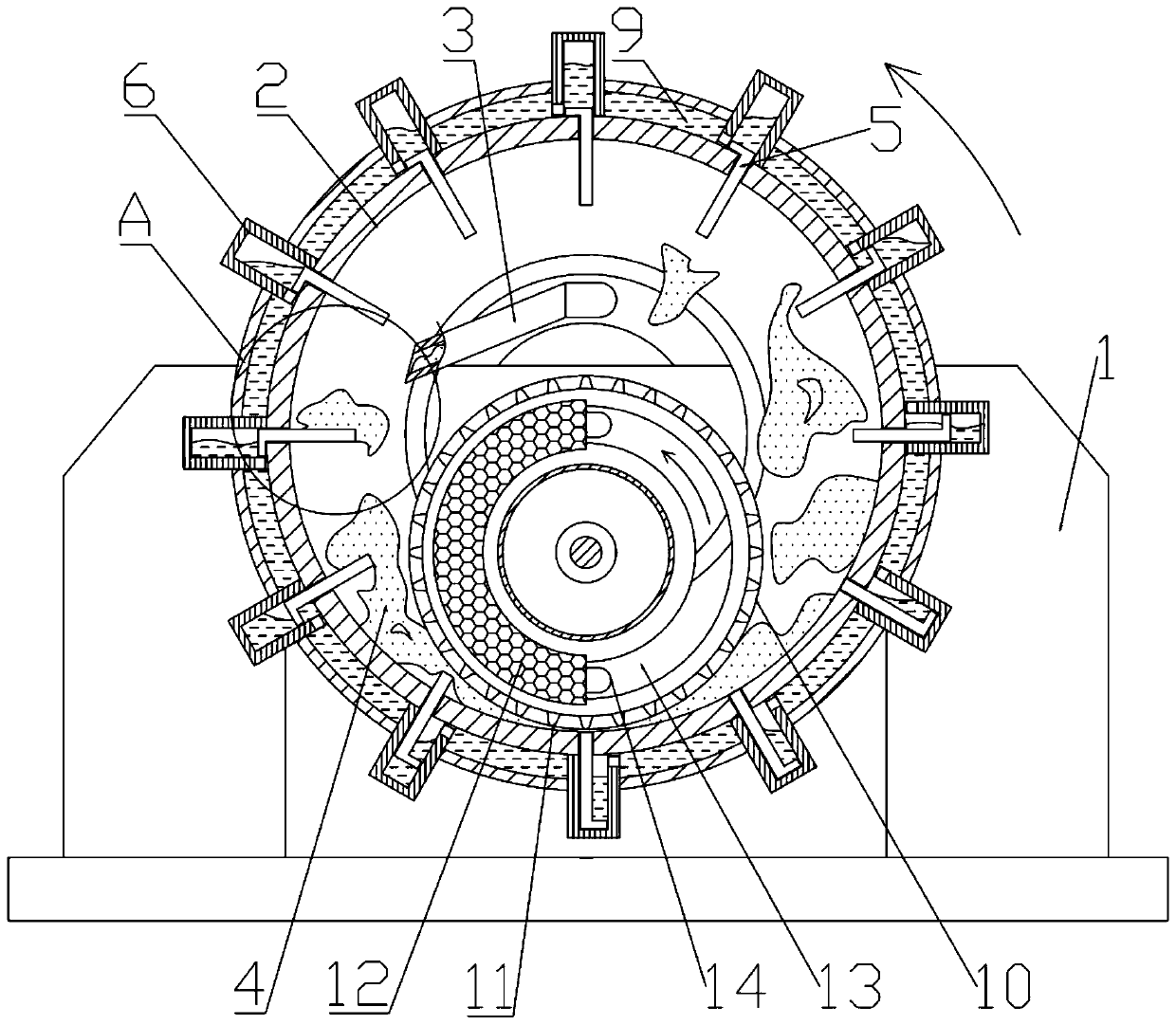

Intelligent double-pan roasting machine

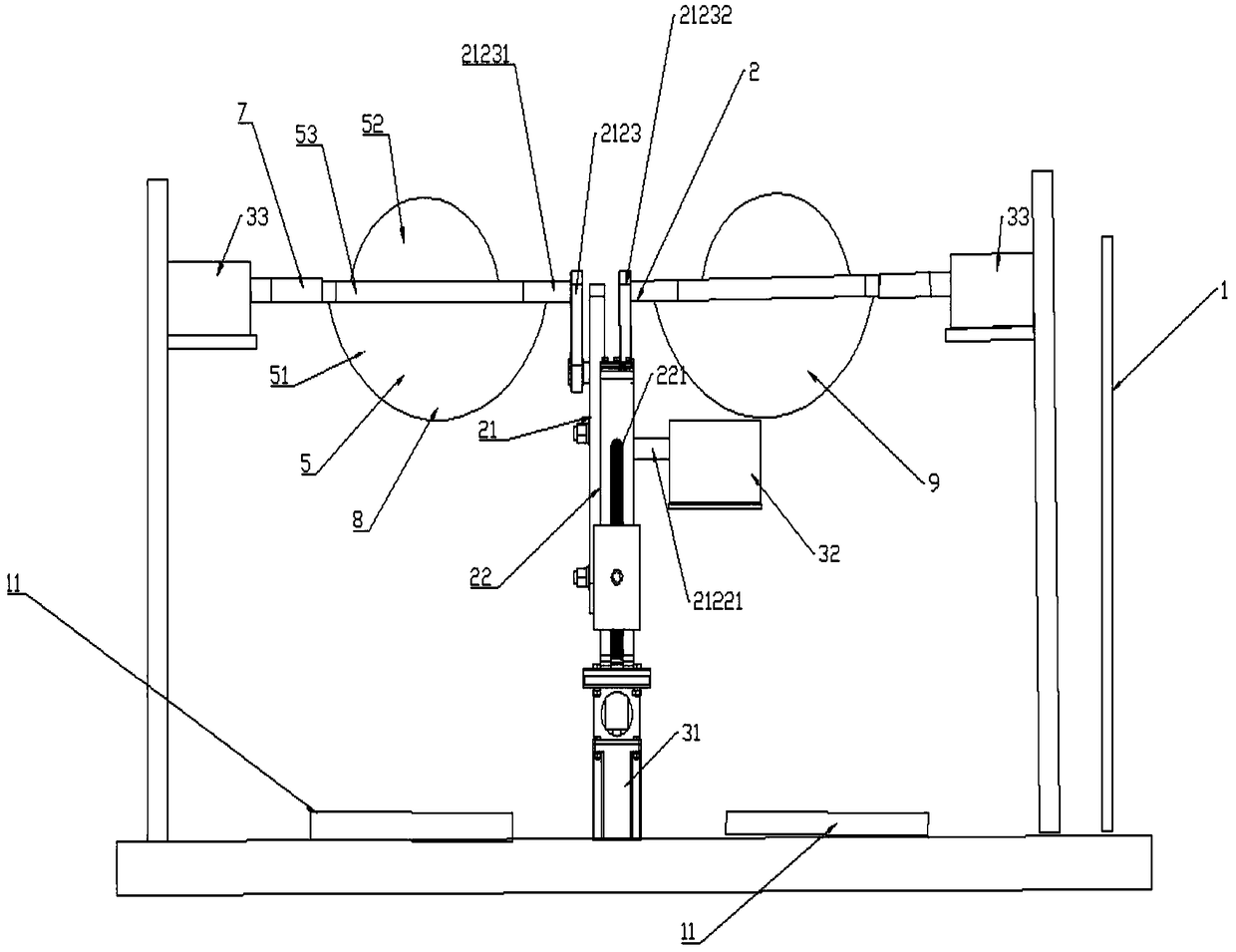

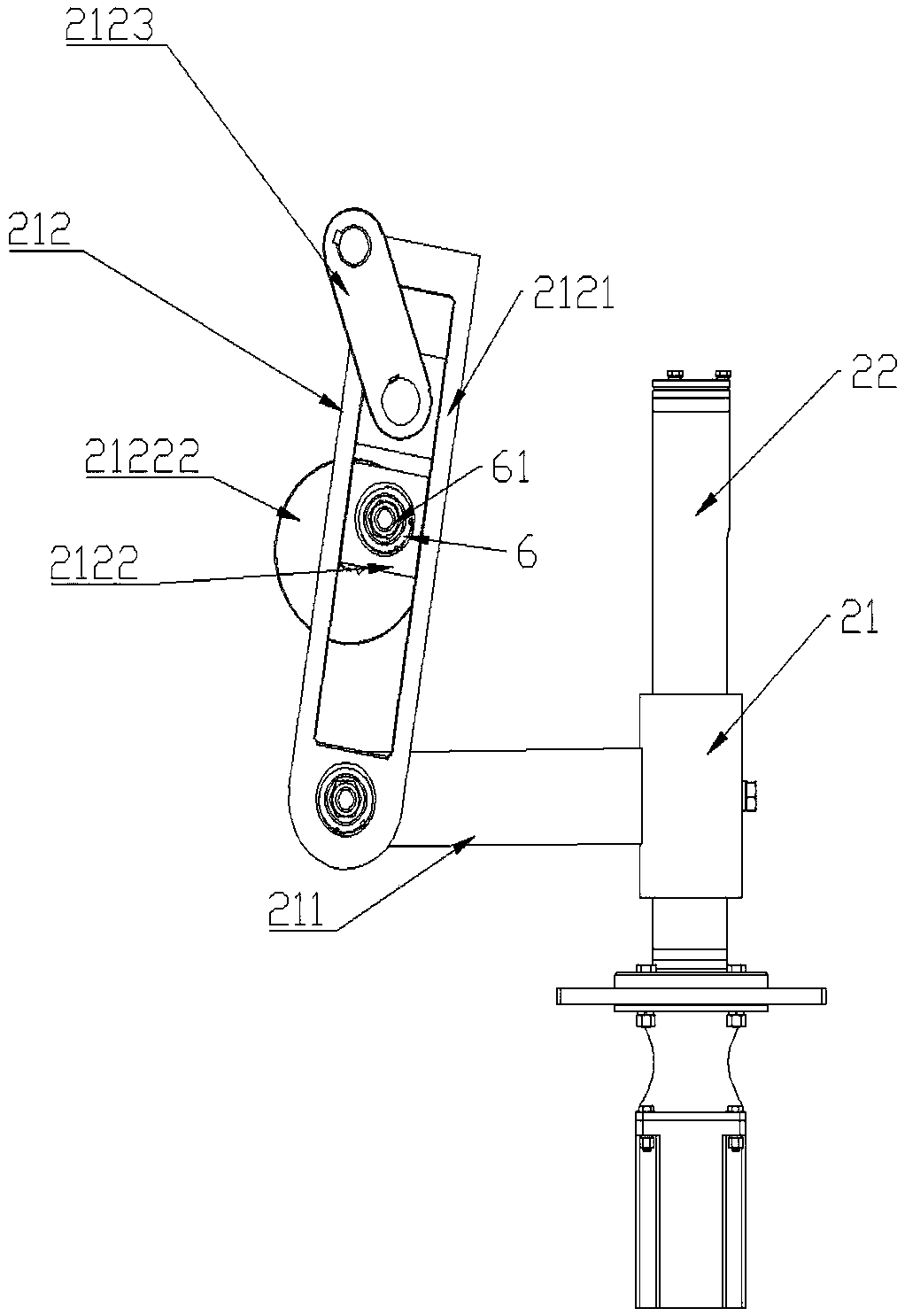

InactiveCN108719513AHigh precisionImprove operabilityPre-extraction tea treatmentEngineeringFrying-pans

The invention relates to the technical field of processing of tea leaves, in particular to an intelligent double-pan roasting machine. The intelligent double-pan roasting machine comprises a transmission mechanism, a power device and tea frying pans, wherein the transmission mechanism comprises a supporting member and a stand column; the supporting member comprises a supporting rod and a swingingmechanism; the supporting rod is hinged to the swinging mechanism; the swinging mechanism comprises a guide rail, a sliding block and a crank shaft; the sliding block is in reciprocating motion in theguide rail; the crank shaft is hinged to the sliding block; the power device comprises a first motor and a second motor; the supporting member is driven by the first motor to move up and down on thestand column; the sliding block is driven by the second motor to move in the guide rail; each tea frying pan comprises a pan body, a frying plate and a fixing rod, wherein the fixing rods are connected with the crank shaft; and each pan body and the corresponding frying plate are respectively connected to the corresponding fixing rod. The intelligent double-pan roasting machine disclosed by the invention has the advantages of being flexible, simple and convenient to operate, high in tea frying efficiency, easy to adjust and low in floor space.

Owner:浙江上洋机械股份有限公司

Processing technology and equipment for stir-frying codonopsis pilosula with agastache rugosus

PendingCN114681502AThe way to realize stir-frying processingEvenly distributedDigestive systemPharmaceutical product form changeCodonopsis pilosulaElectric machinery

The invention relates to the technical field of stir-frying of agastache rugosus and codonopsis pilosula after processing, and discloses a processing technology of fried codonopsis pilosula with agastache rugosus and equipment thereof, and the processing technology of fried codonopsis pilosula with agastache rugosus comprises steps 1-5. The used equipment matched with the processing technology of stir-fried codonopsis pilosula with agastache rugosus comprises a bottom plate, and an inner cavity of a cylinder is provided with a stir-frying chamber capable of containing agastache rugosus and clean codonopsis pilosula; and when the motor drives the driving gear to rotate through the output shaft of the motor, the barrel body can circumferentially rotate on the two groups of clamping components through the driven gear. According to the invention, a fire source in the fire box can continuously heat the cylinder body, the rotation of the output shaft of the motor can drive the rotation of the driven gear, so that the cylinder body can circumferentially rotate on the two groups of clamping parts, and the agastache rugosus and the clean codonopsis pilosula placed in the cylinder body can be heated through the rotation of the cylinder body; and the dough can be continuously turned over in the barrel body, so that the pogostemon villosum and the clean codonopsis pilosula can be stir-fried.

Owner:常州卫生高等职业技术学校

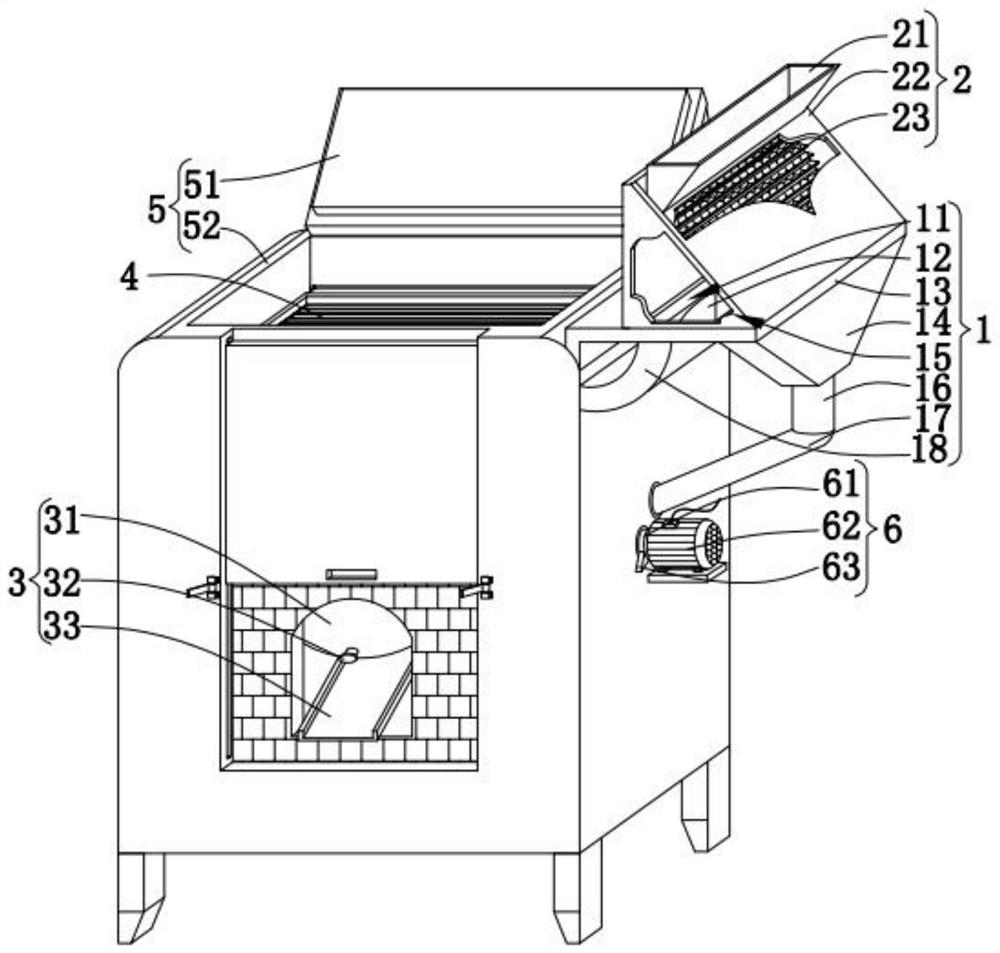

All-digital intelligent variable-frequency heating herbal medicine roaster

PendingCN114344155AAchieve stir fryEvenly heatedPharmaceutical product form changeDomestic articlesPhysicsMedicinal herbs

The invention relates to the technical field of herbal medicine roaster, in particular to an all-digital intelligent variable-frequency heating herbal medicine roaster which comprises a base, a rotatable slotting roller is arranged on the base, the interior of the slotting roller is hollow and used for containing medicinal materials, the slotting roller is sleeved with a plurality of electromagnetic induction coils, and the electromagnetic induction coils are externally connected with an electromagnetic heating controller. By the adoption of the structural arrangement, the electromagnetic induction coil is used for heating the rotary slotting roller, the heat efficiency is high, meanwhile, the rotary slotting roller can stir-fry medicinal materials in the slotting roller, then the medicinal materials are heated evenly, the electromagnetic heating controller is used for controlling the electromagnetic induction coil to work, accurate temperature control and intelligent temperature compensation are achieved, and the electromagnetic heating effect is good. The stability is good. The whole stir-frying treatment process is free of waste gas emission, free of peculiar smell, free of influence on the air quality and low in operation cost, and is ideal stir-frying processing equipment.

Owner:SHENZHEN ZENEN ELECTRONICS TECH CO LTD

A staged combustion equipment for a suspension roaster

The invention relates to the field of combustion of suspension roasting furnaces, in particular to suspension roasting furnace grading combustion equipment which comprises a separated dropping mechanism, a screening mechanism, a first combustion mechanism, a second combustion mechanism, a supporting mechanism, a drive mechanism and a linkage mechanism. For the suspension roasting furnace grading combustion equipment, the drive mechanism is matched with a first combustion mechanism in a furnace body to realize heating of larger materials, heating is more comprehensive as the first combustion mechanism is closer to the bottom of the furnace body, and the linkage mechanism is used for swinging the second combustion mechanism arranged in the furnace body while the first combustion mechanism moves in a reciprocating manner, so that stir-frying of materials in a stir-frying bucket in a fixed frame can be realized, and graded heating, comprehensive reaction and uniform stirring are realized;and the furnace body side wall mechanism is matched with the screening mechanism to be used for sorting coarse and fine materials needing to be heated, and the separated dropping mechanism enables thelarger materials to flow into a stir-frying pan and the stir-frying bucket from a coarse material hole and a fine material hole respectively for graded heating after sorting, so that the workload isreduced, and the time and the labor are saved.

Owner:南京六创科技发展有限公司

Tea leaf stir-frying and drying device

InactiveCN107897398AStir fry evenlyImprove drying efficiencyPre-extraction tea treatmentDrive wheelEngineering

The invention discloses a tea stir frying and drying device, which relates to the technical field of tea processing equipment and is used to solve the technical problems of low drying efficiency of tea leaves in the prior art. The motor box is equipped with a bevel gear transmission mechanism and a motor composed of three bevel gears. The three bevel gears are meshed with each other and rotate, driving the drying box connected to one of the bevel gears to rotate, and then driving The driving wheel outside the drying box rotates, and the driving wheel drives the driven wheel to rotate through the belt. The other end of the driven wheel is connected to the fourth rotating shaft, and the four ends of the rotating shaft extend into the tea frying box. It is installed on the top of the drying box, and a drying cover is arranged above the drying box. By setting a bevel gear transmission mechanism in the present invention, the stir-frying and drying of tea leaves can be carried out synchronously, and the drying efficiency of tea leaves can be improved. It has the advantages of energy saving and environmental protection.

Owner:弘毅天承知识产权股份有限公司

A new type of cooking stove

ActiveCN109330345BEvenly heatedImprove rolling effectCooking-vessel lids/coversCooking insertsCookerShovel

The invention provides a new type of cooking stove, which comprises an outer pot, a pot cover, an inner pot accommodated in the outer pot, and a stirring shovel fixed on the pot cover. The outer pot is provided with a A drive mechanism, the outer pot is provided with a limit mechanism to limit the circumferential rotation of the pot cover so that the stirring shovel and the inner pot form relative rotation. The invention adopts the method of not rotating the stirring shovel and rotating the inner pot to realize stir-frying of food materials, and the inner pot rotates on the heating device, so that the heating of each part of the inner pot is more uniform, and the cooked dishes are more delicious.

Owner:JOYOUNG CO LTD

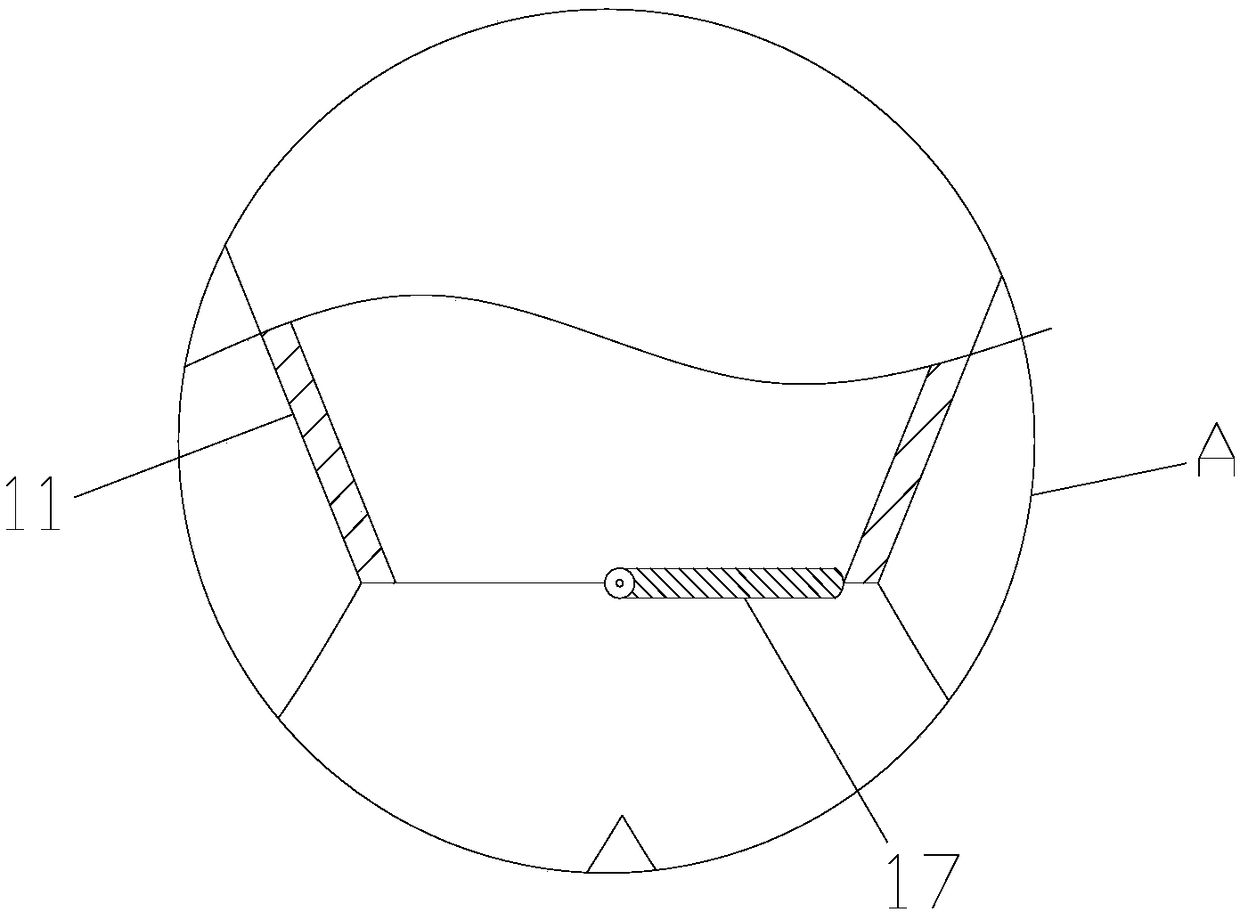

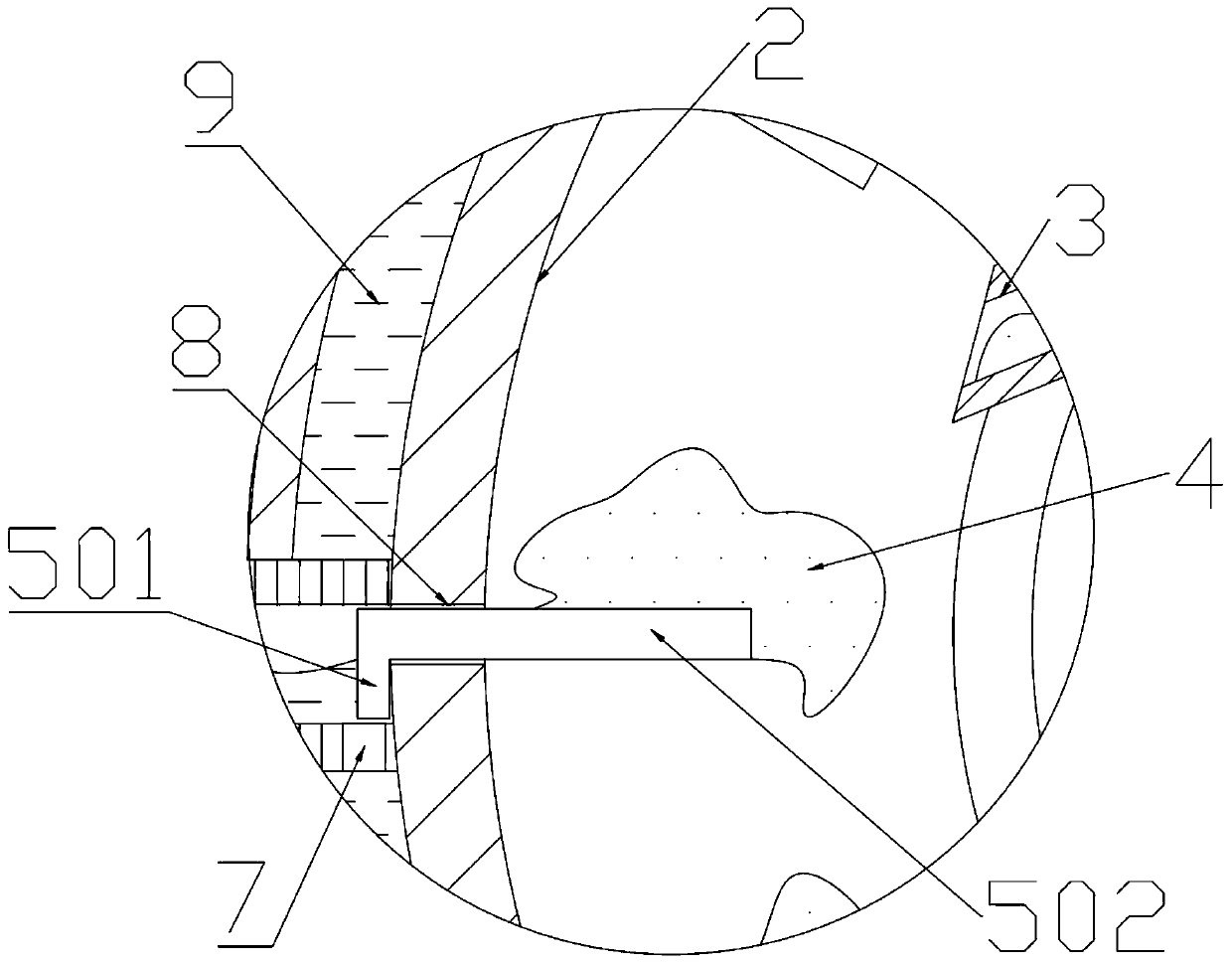

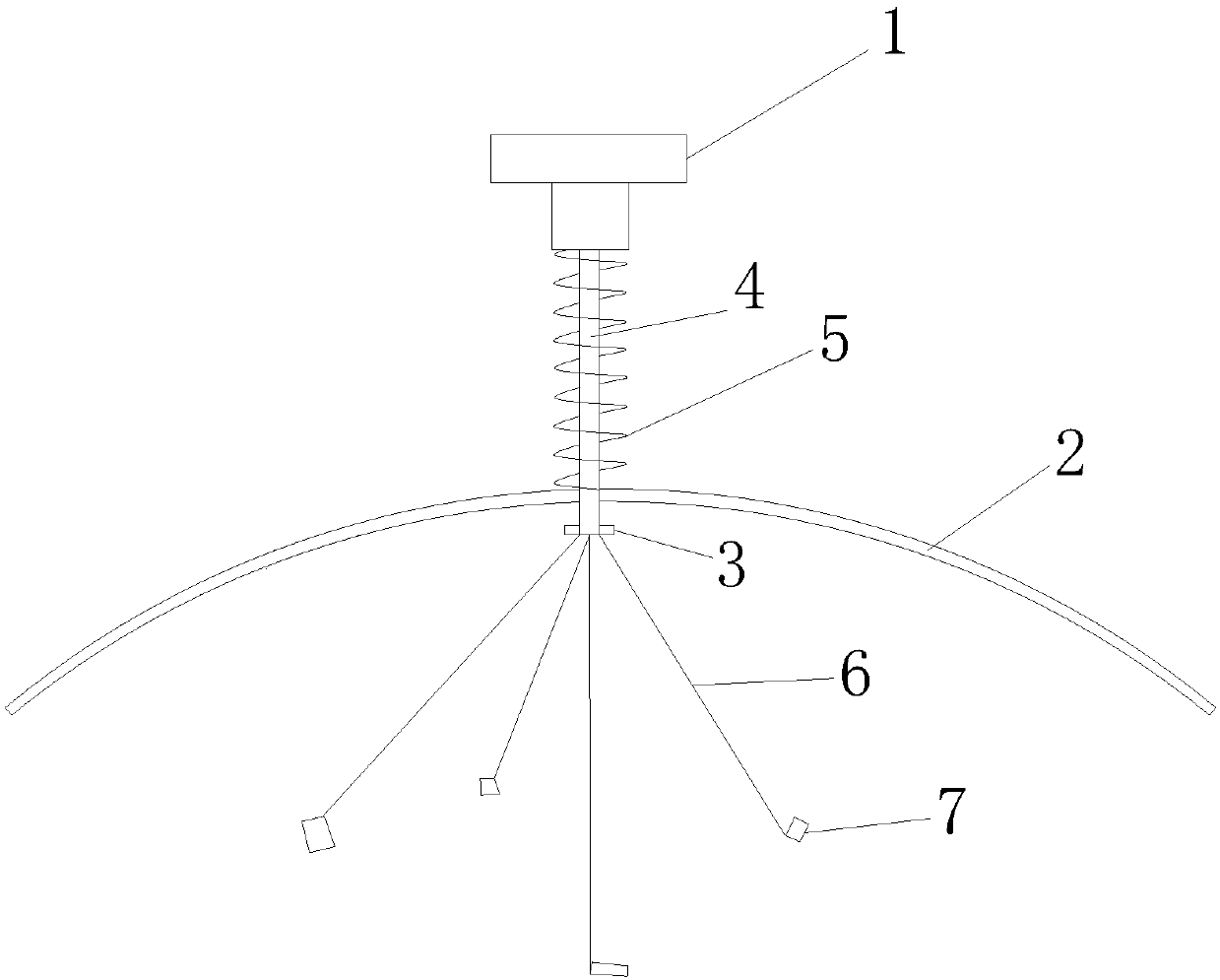

Stir-fry pan cover for realizing stir-frying

The invention discloses a stir-frying wok cover, which comprises a cover body (2) and a handle (1), and also includes a transmission shaft (4), a spring (5), several connecting rods (6) and several stir-frying pots. (7), the middle part of the upper end of the cover body (2) is provided with a through hole, the upper end of the transmission shaft (4) passes through the through hole and the spring (5) is fixedly connected with the handle (1), and the lower end of the transmission shaft (4) is provided with a limit block (3), so that the cover (2) is movably connected with the transmission shaft (4) and does not fall off; one end of the connecting rod (6) is fixedly connected with the lower end of the transmission shaft (4), and the other end is fixedly connected with the stir-fry piece (7) . With the pot cover of the present invention, the pot cover can be placed on the wok when cooking, and the handle (1) can be pressed down and turned to realize stir-frying of the vegetables in the wok, and the oil in the wok will not splash On people's upper arms, it is practical and safe to prevent scalding the arms.

Owner:庄孝洪

Tea processing equipment

InactiveCN108522672APlay the role of dryingUniform drying effectPre-extraction tea treatmentTea flavoringFan bladeFermentation

The invention discloses tea processing equipment. The tea processing equipment comprises a base, wherein an arc-shaped table, a mixing mechanism and a power mechanism are arranged sequentially from top to bottom; the mixing mechanism comprises a circular shaft and box bodies arranged symmetrically on both sides of the circular shaft; the circular shaft is rotationally connected with the base and arotating drum is arranged on the circular shaft; an automatic reversion and rotation feeding mechanism and an automatic reversion and rotation discharging mechanism are arranged on an arc surface ofthe rotating drum; a collecting box is arranged between the two box bodies, a collecting port is formed at the collecting box, and abutting blocks abutted against the rotating drum are arranged on both sides of the collecting port; material inlets and material outlets are formed at the two box bodies; an accessory shaft and a screen are arranged in the box body on the right side and a first fan blade is arranged on the accessory shaft; a side hole is formed at a side wall of the box body on the right side, the side wall of the box body on the right side is in slip connection with a side plateabutted against the first fan blade, and a fourth spring is arranged between the side plate and an inner wall of the box body on the right side; and an air tube communicating with the collecting box is arranged on the side hole. The scheme mainly solves the problems of poor effects of water removal and fermentation of tea at present.

Owner:贵州省凤冈县永田露茶业有限公司

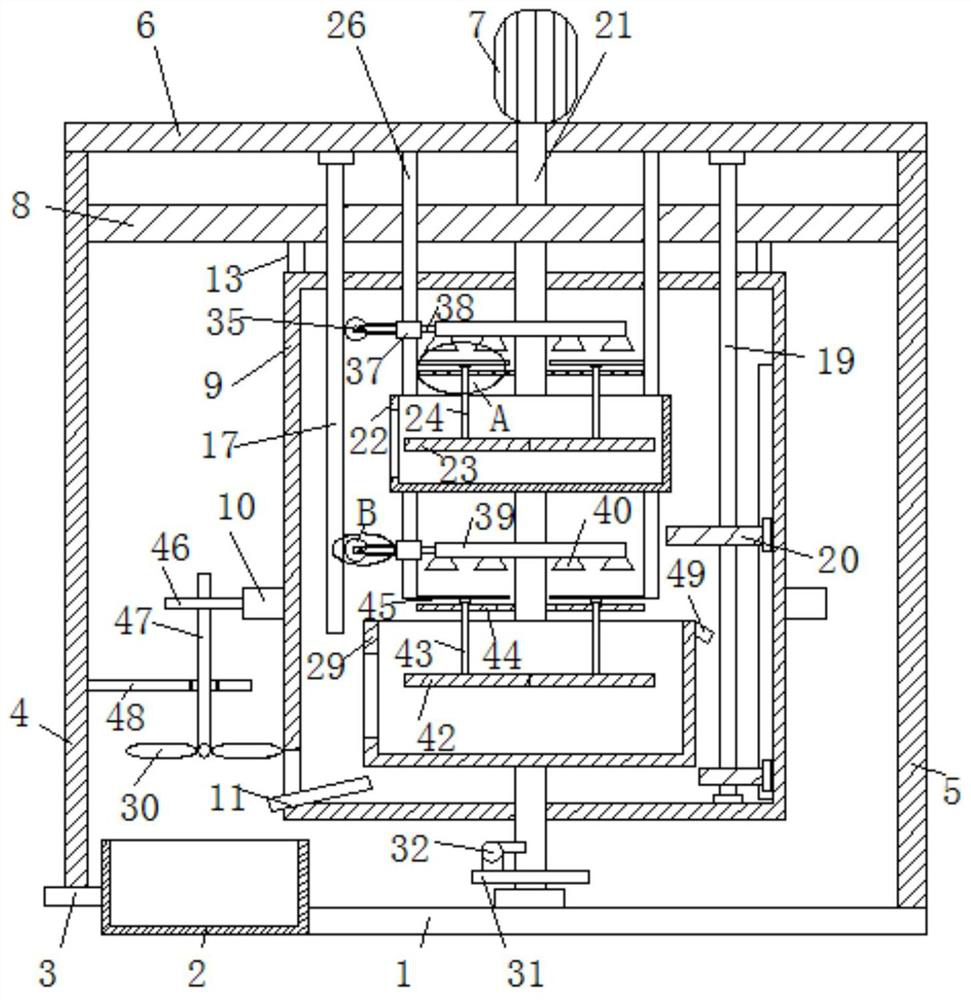

An automated kitchen set

ActiveCN110558822BEasy to absorbRealize the work of automatic feedingWarming devicesElectric machineryProcess engineering

An automatic kitchen set, comprising: a cabinet part, a stir-frying mechanism, a seasoning box part, and a wok part; the cabinet part is used in conjunction with the seasoning box part; the stir-frying mechanism is used in conjunction with the wok part; to store and absorb the seasoning box part; the stir-frying mechanism can stir fry the wok part; the seasoning box part is used to store seasoning; the wok part is used to stir-fry ingredients; Sliding horizontally, the vertical screw motor drives the vertical screw slider to slide vertically, so that the movable suction mechanism can absorb and place the magnet seat of the seasoning box part; then through the bottom connecting arm, middle connecting arm, electric push rod A , The electric push rod B and the top telescopic arm work in coordination, so as to control the gripper to grab the part of the wok to realize stir frying.

Owner:胡佳威

Bionic manual tea stir-frying processing device

InactiveCN113317367AAchieve stir fryUniform heatingPre-extraction tea treatmentEngineeringMechanical drive

The invention discloses a bionic manual tea stir-frying processing device. The bionic manual tea stir-frying processing device comprises a box body, wherein a stir-frying cavity is formed in the box body, a dumping device used for automatically stir-frying tea leaves is arranged in the stir-frying cavity, and the dumping device comprises a second sliding groove formed in the inner wall of the stir-frying cavity. According to relevant knowledge of mechanical transmission, the tea leaves are stir-fried through a connecting rod transmission mechanism and mechanical transmission between magnets and gravity in the device, the tea leaves in the device are stir-fried by adopting an arc surface to effectively enable the tea leaves to be uniformly heated, and through a rotating plate on a stir-frying main plate rotating on the device, when the rotating plate rotates by an angle, the middle rotating plate can be automatically opened, the tea leaves are effectively stir-fried, the tea leaves can be uniformly stir-fried, the situation that the tea leaves are coagulated into clusters is also effectively prevented, and the stir-fried tea leaves are subjected to bionic rolling and pressing, so that the processed tea leaves can be automatically rolled.

Owner:东莞市菲韵科技有限公司

Rotary drum type tea frying machine with strip rolling function for tea processing

PendingCN113100300AAchieve stir fryAchieve dryingPre-extraction tea treatmentClimate change adaptationSpiral bladeTea leaf

The invention discloses a rotary drum type tea frying machine with a strip rolling function for tea processing. The rotary drum type tea frying machine comprises an outer sleeve, four supporting legs are fixedly arranged at the bottom end of the outer sleeve; an inclined discharge nozzle is fixedly arranged at one end, close to the bottom side, of the outer sleeve; a first inner ring is fixedly arranged on the inner wall of one end, close to the inclined discharge nozzle, of the outer sleeve; a second inner ring is fixedly arranged on the inner wall of the end, away from the inclined discharging nozzle, of the outer sleeve, and a vertical fixing block is fixedly arranged at the end, close to the inclined discharging nozzle, of the outer sleeve. The tea leaves stored in the material storage barrel are pumped into the inner rotating barrel through the arranged discharging rotating shaft and the rotation of the spiral blade in the right-angle discharging pipe; the arranged inner rotary drum rotates and is heated by the spiral heating wire, so that the tea leaves are stir-fried and dried; the curved-surface kneading strip rotating blocks arranged in the inner rotating drum and the inner wall of the inner rotating drum rotate in opposite directions, so that the tea leaves are kneaded into rolled strips; in conclusion, the problems in the background technology are solved.

Owner:施明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com