Novel oil pouring kettle

A new type of oil pouring technology, applied in the field of oil pouring pots, can solve the problems of user inconvenience, bacteria breeding, troublesome operation, etc., and achieve the effects of easy cleaning, sanitation saving, and hygienic assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

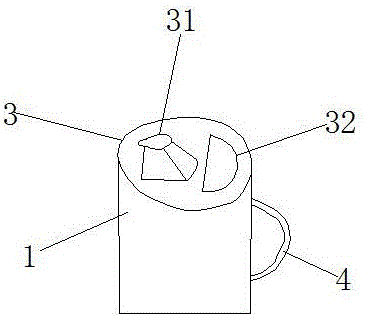

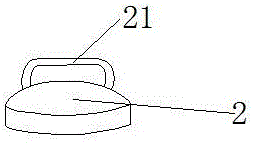

[0024] The structural representation of a new type of oil pouring pot in this embodiment is as follows: Figure 1 to Figure 2 As shown, it includes a pot body 1 and a pot cover 2, and the pot cover 2 is sealed on the pot body 1; Groove 32 ; the height of the oil nipple 31 is higher than that of the upper cover 3 .

[0025] When using the oil pouring pot to pour oil, the pot cover 2 is disassembled from the pot body 1, the oil flows into the pot from the oil nozzle 31, and the oil flowing down from the outer wall of the oil nozzle 31 flows back to the pot body 1 through the return groove 32 after pouring the oil. inside, so that the oil will not flow to the outer wall of the pot body 1, which saves oil and ensures hygiene; after frying things, pour the oil in the oil pan into the pot body 1 through the return groove 32, which is easy to operate and provides User convenience.

[0026] Wherein, the oil nozzle 31 is an obliquely upward streamlined hook structure. This setting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com