Dust-removing mop

A technology of mop and connecting parts, which is applied in the direction of cleaning carpets, floors, cleaning equipment, etc., and can solve problems such as troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

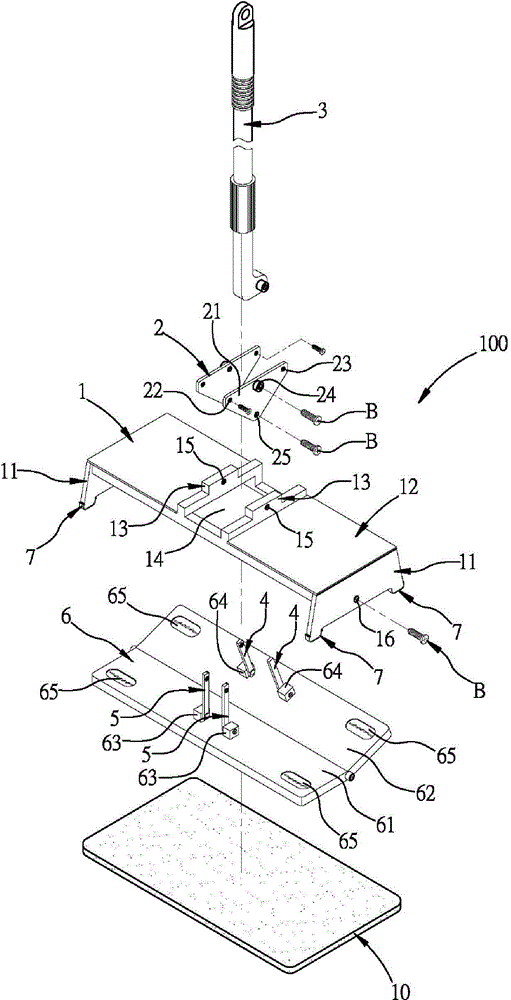

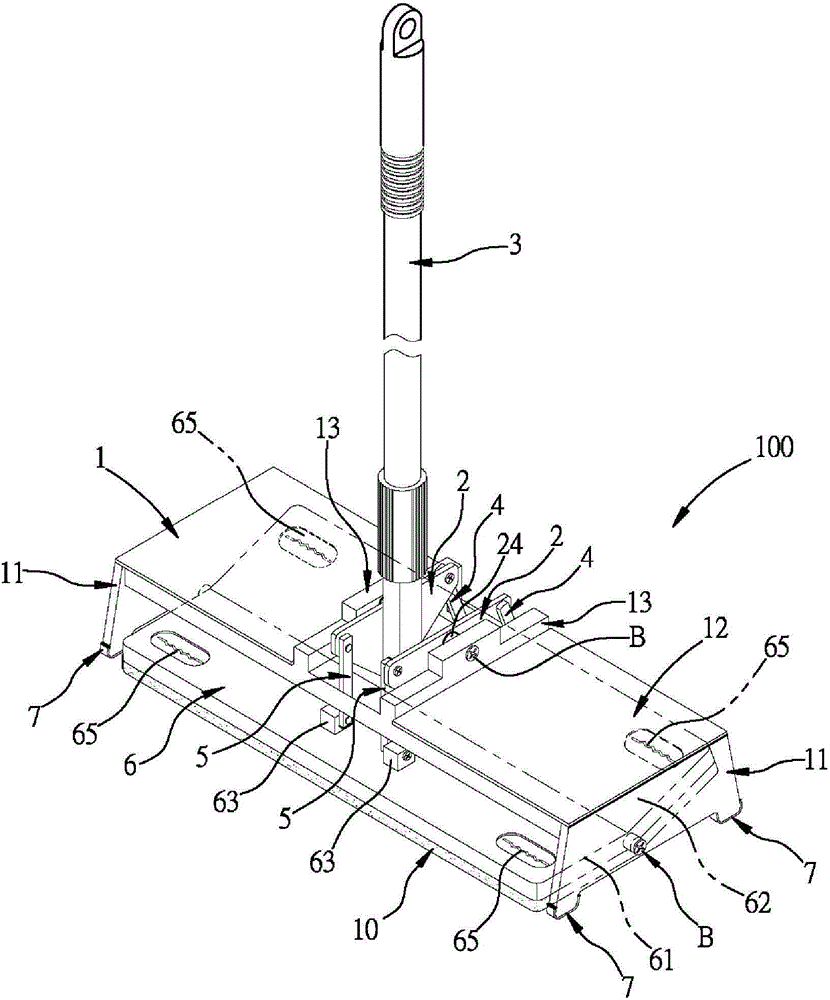

[0056] Please also see Figure 2 to Figure 7 As shown, the dust removal mop 100 of the present invention includes a base 1 , two first connectors 2 , a handle 3 , two second connectors 4 , two third connectors 5 , and a board 6 .

[0057] The base 1 has two side plate portions 11, a flat plate portion 12, and two raised portions 13. The two side plate portions 11 extend downward from both axial ends of the plate portion 12, and the center of the plate portion 12 has a slot 14. The two protruding parts 13 are respectively located at both ends of the slot 14, and the axial direction of each protruding part 13 is parallel to the radial direction of the flat plate part 12, and a first pivot joint is formed at the center of each protruding part 13. Holes 15 , and a second pivot hole 16 is formed at the center of each side plate portion 11 .

[0058] Each first connector 2 can be an inverted triangle, and each first connector 2 has a body 21, a front upper connection hole 22, a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com