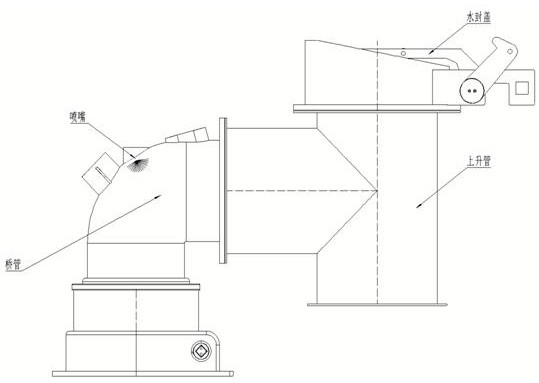

Nozzle capable of intelligently improving suction force in ascending pipe

A nozzle and suction technology, applied in the field of nozzles that intelligently improve the suction inside the rising pipe, can solve the problems of small negative impact of the rising pipe and increase the service life of the workpiece, and achieve the effect of reducing the escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

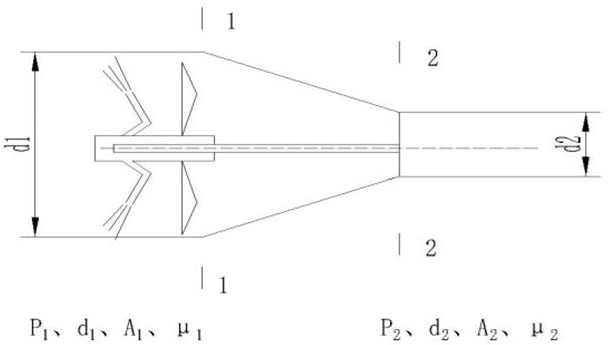

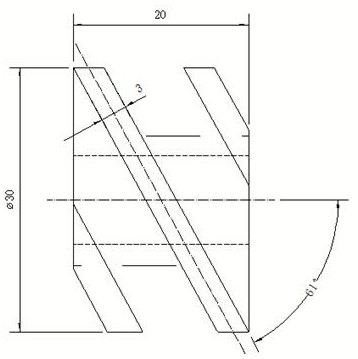

[0026] In order to meet the different requirements of coking plant users for the suction of the riser, nozzles of different specifications and sizes are selected, and the invention proposes the requirements that the nozzles must meet. In the specific implementation, the suction force of -800Pa is generated according to the customer's requirements, and the design and calculation process is as follows:

[0027] Working conditions: the medium in the nozzle is ammonia water, ammonia water (density β=0.91g / cm 3 :) It is based on the inlet pressure of the ammonia water entering the bridge pipe. If it is the outlet of the high-pressure ammonia water pump, the pressure loss needs to be considered. The inlet pressure is 2.5~3.0MPa, the inlet diameter is DN25 flange connection, and the nozzle is connected by thread.

[0028] The nozzle is Laval type as an example, the Bernoulli equation is applied to the two sections of 1-1 and 2-2, and the energy is conserved at these two sections:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com