a filter press

A filter press and rack technology, applied in the field of solid-liquid separation machinery, can solve the problems of unfavorable recycling, long rack, large water consumption, etc., and achieve the effect of reducing the length of the fuselage and optimizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

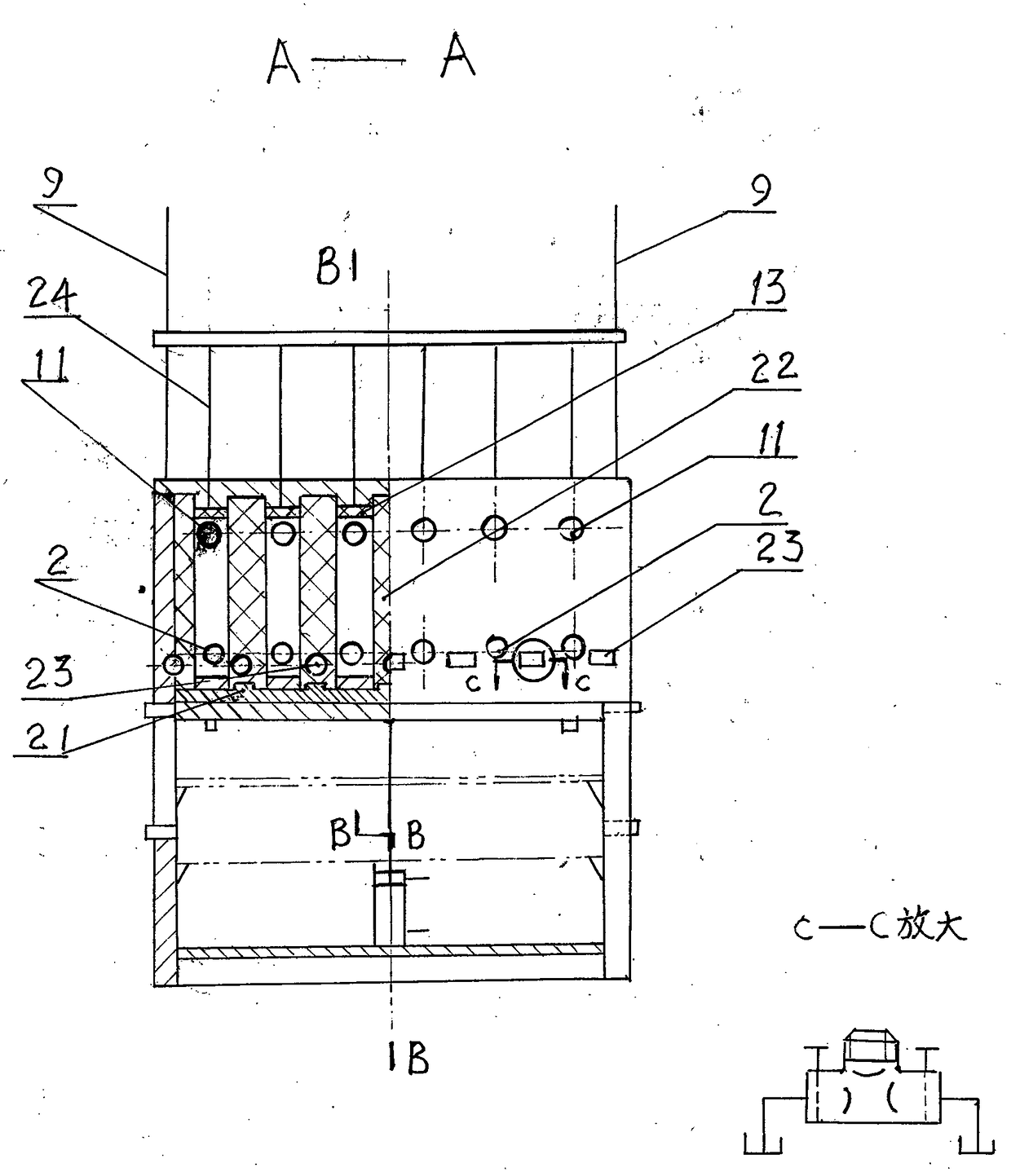

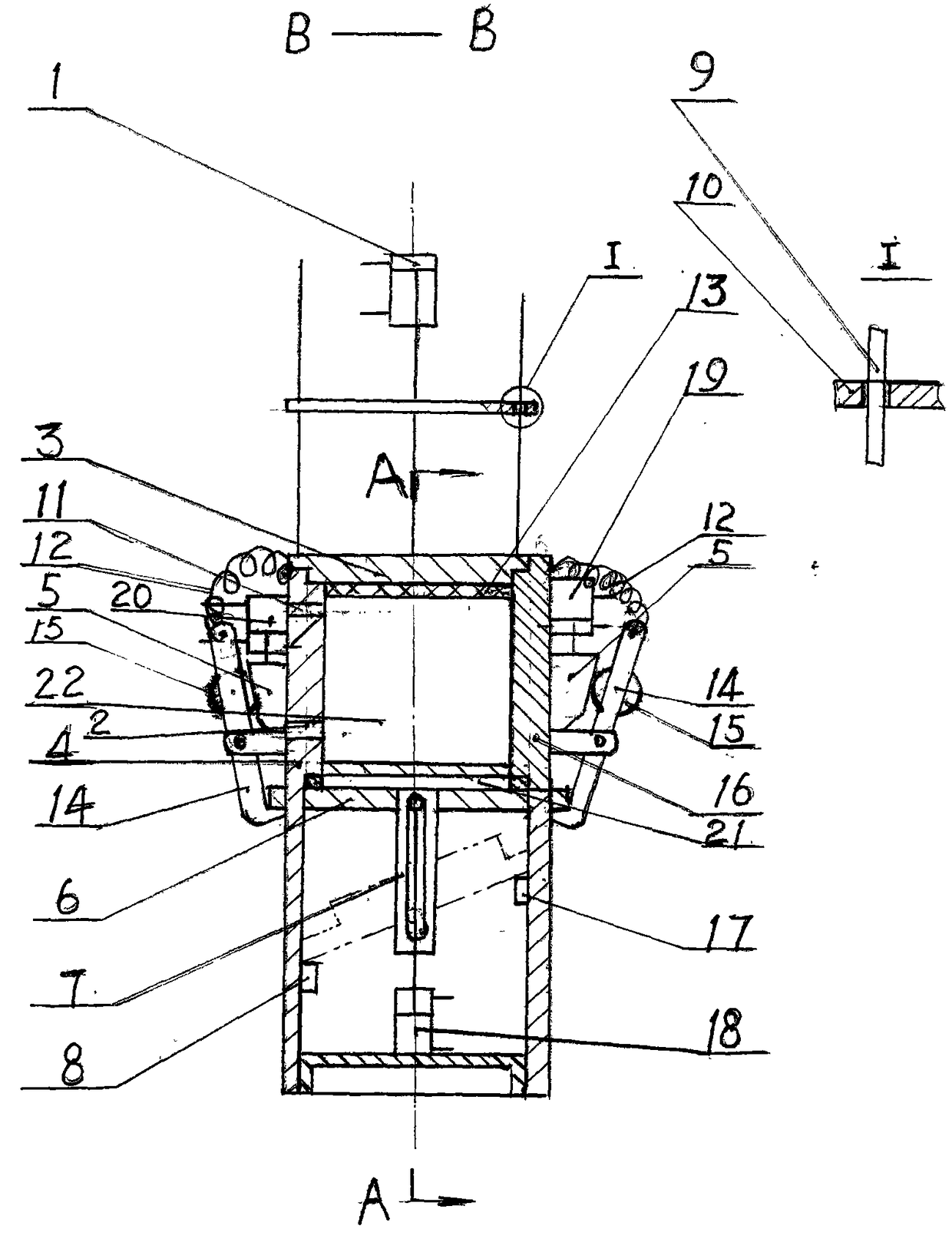

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] figure 1 , figure 2 It is an embodiment of the present invention, first remove the front plate 16, put the bottom of the filter plate 22 on the boss of the grid plate 21, push the filter plate 22 to insert it into the long groove of the cover plate 3 and the rear plate of the frame 4 , and then the front plate 16 is fixed on the frame 4 with screws, the lower hydraulic cylinder 18 is started to press the bottom plate 6, and the front and rear hydraulic cylinders 19, 20 push the slanting block 5, and the slanting block 5 pushes the wheel 15 to fasten the claw 14 Base plate 6, shut down, front and rear hydraulic cylinders 18, 19, 20, open feed valve 2 to feed the filter chamber, open the filtrate end of two-way liquid outlet valve 23 simultaneously, carry out pressure filtration.

[0014] At the end of the filter press, stop feeding, start the upper hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com