Special hub outer circle polishing machine

A technology for polishing machines and hubs, which is applied to surface polishing machine tools, grinding/polishing equipment, and grinding workpiece supports, etc. It can solve problems such as low production efficiency, difficulty in polishing uniformly, and defects in polishing quality, and achieves simple and fast structure. The effect of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments:

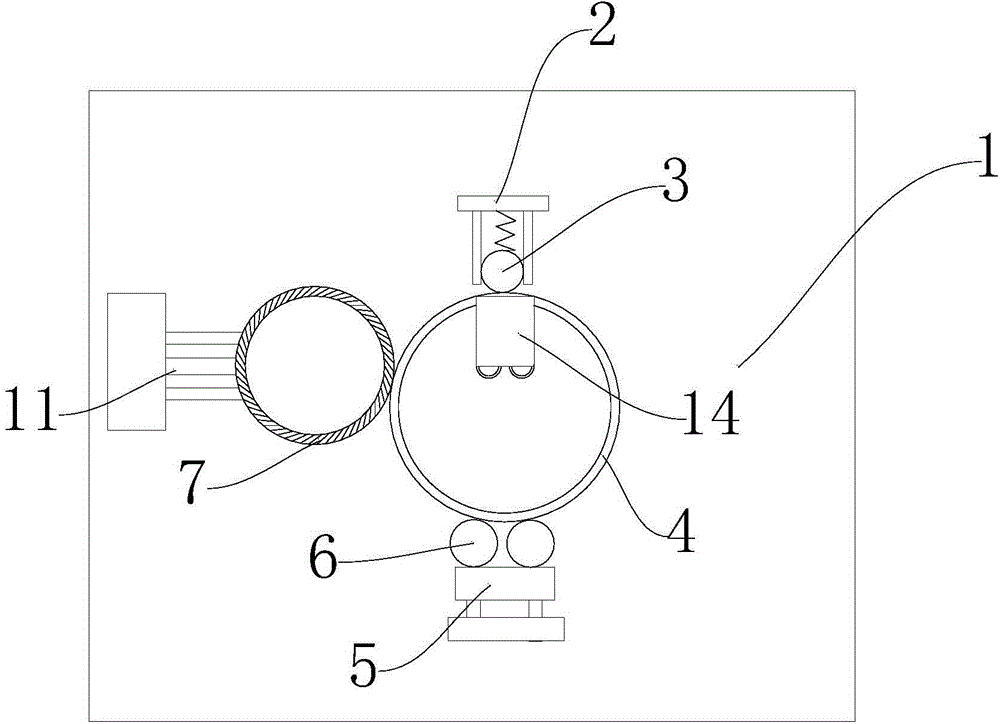

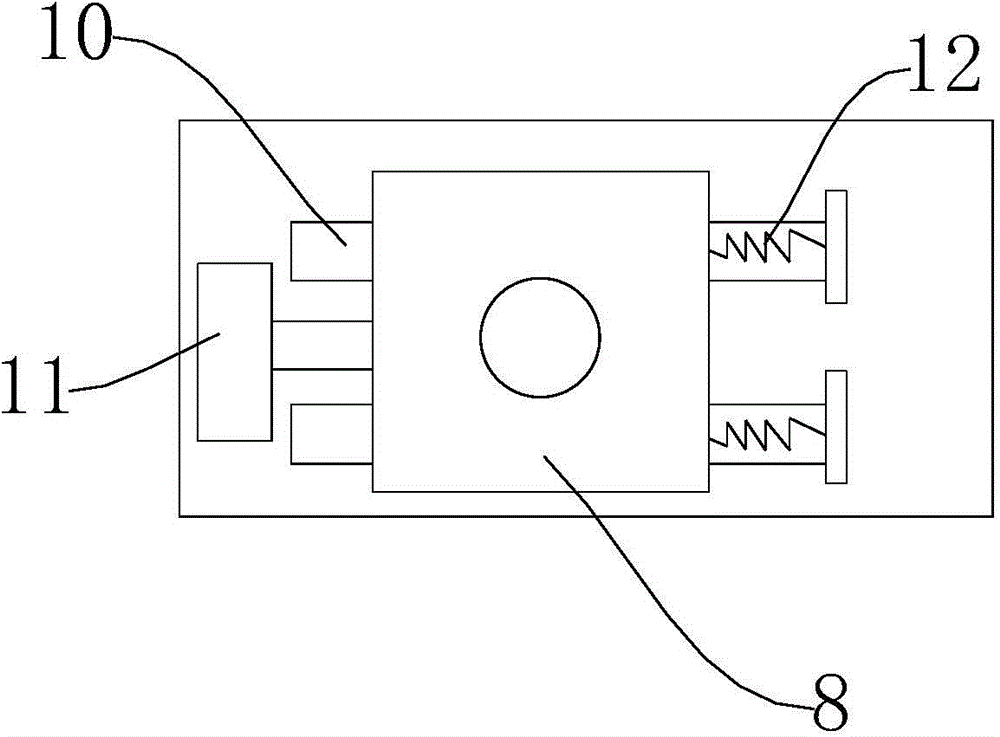

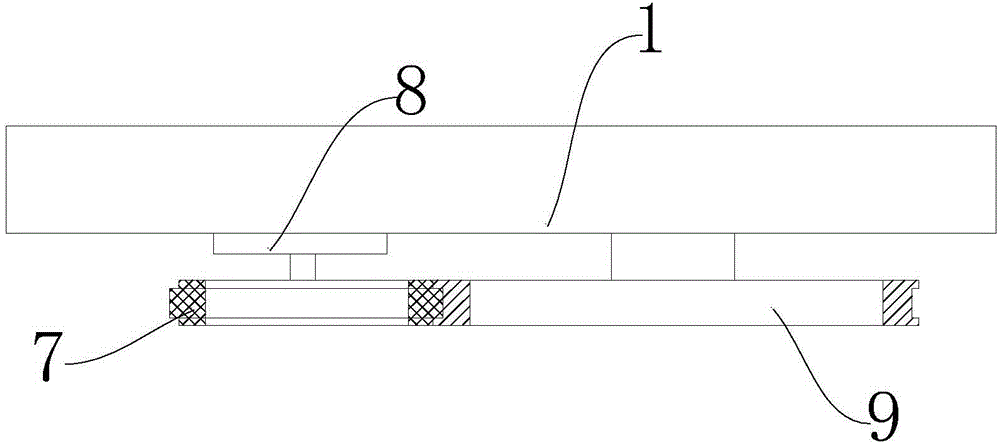

[0016] See Figure 1 to Figure 2 A special cylindrical polishing machine for wheel hubs is shown, including a polishing machine body 1, on which a support wheel 6 that can move up and down and can automatically rotate is arranged in a direction opposite to the support wheel 6 There is a top tightening wheel 3, the top tightening wheel 3 is connected to the guide frame groove 2 provided on the polishing machine body 1 through a return spring, and the polishing machine body 1 is also provided with a thousand-impeller wheel 7 for polishing the outer circle of the hub , The thousand-impeller wheel 7 is driven by a thousand-impeller motor 8 arranged on the slide rail 10. The thousand-impeller motor 8 is provided with a push rod cylinder 11 on one side and a return spring 12 on the other side. The polishing machine The main body 1 is further provided with a guiding mechanis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap