A toothless sprocket for use with a chain saw on a stone cutting machine

A cutting machine and chain saw technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of abrasion, affecting stone cutting quality, short life, etc., and achieve long service life, low noise, and small cutting seam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

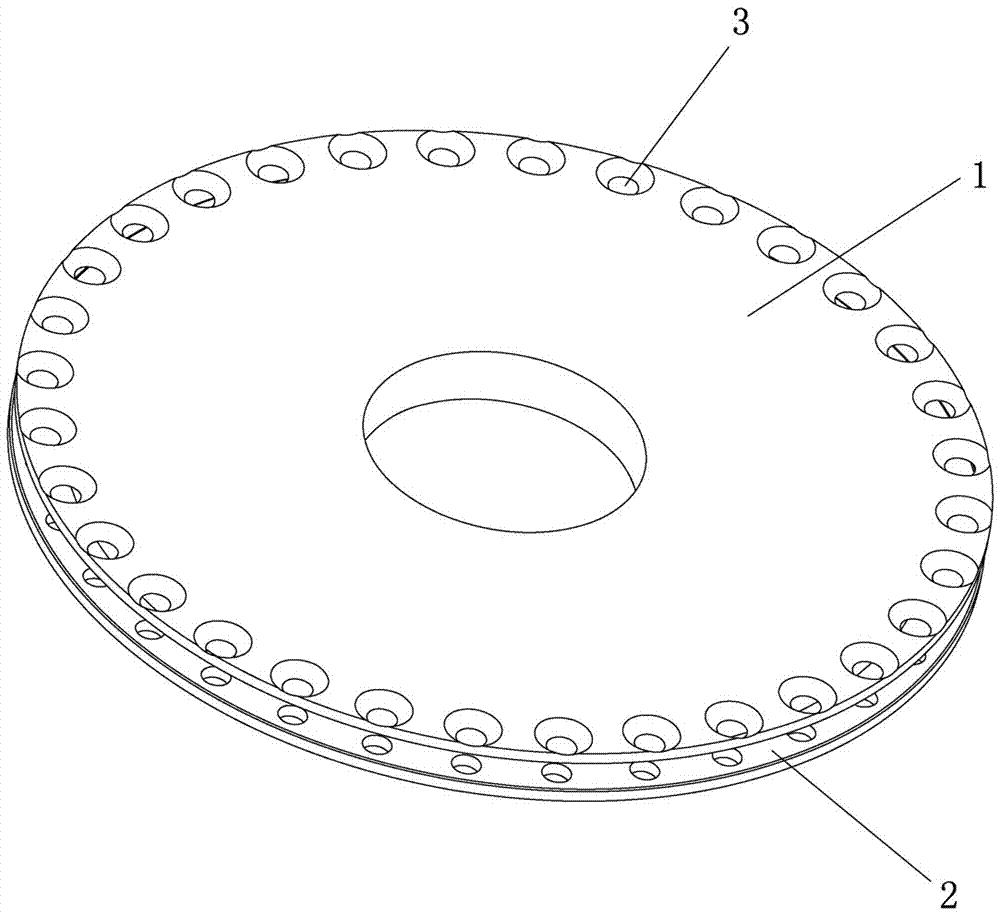

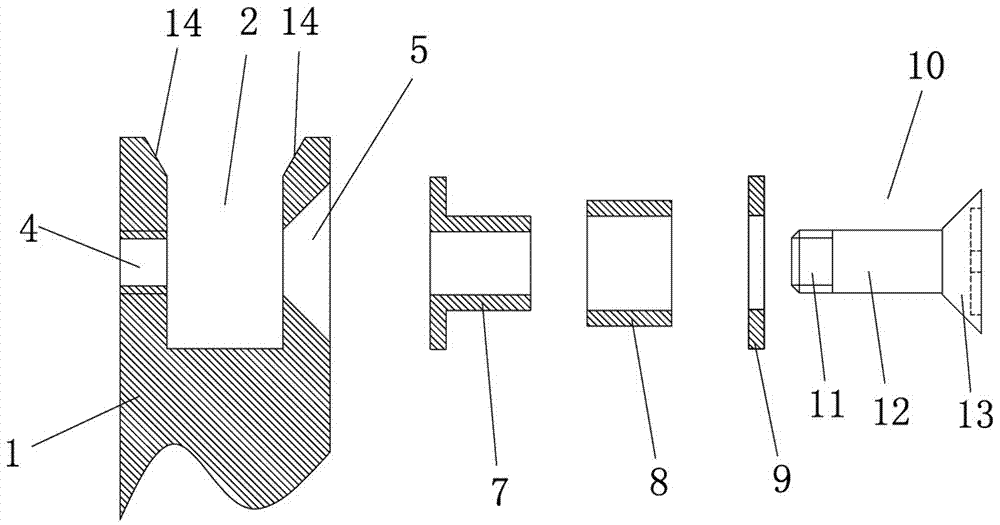

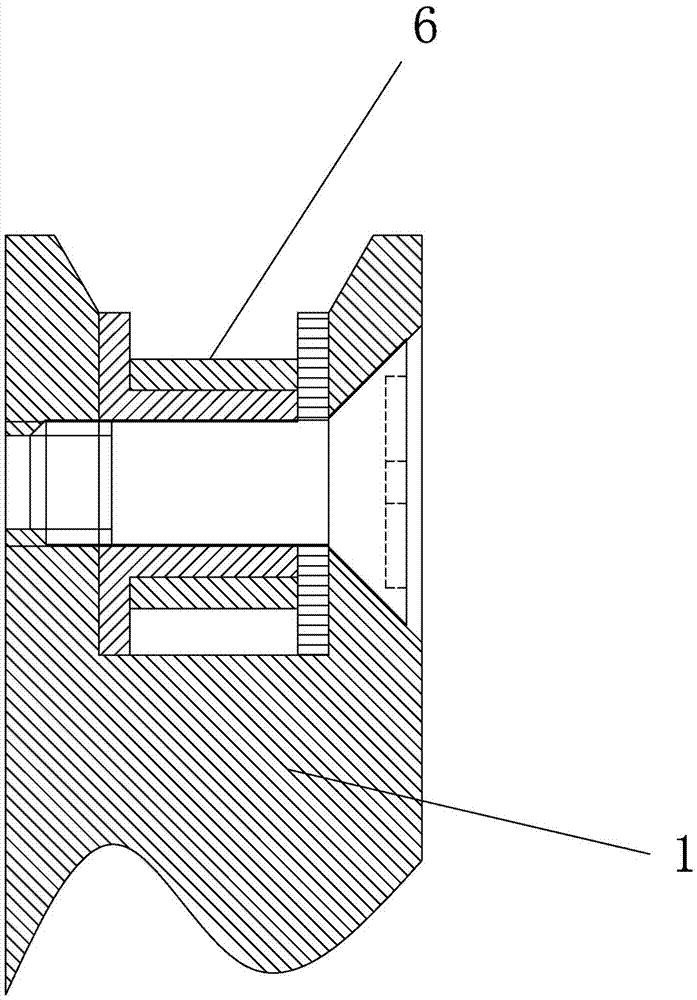

[0019] The toothless sprocket on the stone cutting machine of the present invention, such as figure 1 -9, one of the solutions: it includes a sprocket. The sprocket 1 is provided with grooves 2 along the radial direction. The grooves 2 of the sprocket are provided with a number of through holes suitable for oblique taper head screws. Hole 3; one end of the through hole 3 is a tooth hole 4, and the other end of the through hole 3 is a tapered hole 5; a roller 6 is built in the position of each through hole 3 of the groove 2; the roller 6 is composed of flange bearing 7, steel sleeve 8, thrust washer 9, oblique taper head screw 10; the oblique taper head screw 10 is provided with a thread 11 at the end, and the middle section is a cylindrical screw 12, and its initial section It is the tapered head 13; in the groove 2, the steel sleeve 8 is tightly fitted outside the flange bearing 7, the thrust washer 9 is arranged on the thin end side of the flange bearing 7, and the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com