Chain saw matched with toothless chain wheel of stone cutting machine

A chain saw and toothed sprocket technology, applied in the field of chain saws, can solve the problems of affecting stone cutting quality, short service life, high temperature, etc., and achieve the effect of small cutting seam, long service life and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

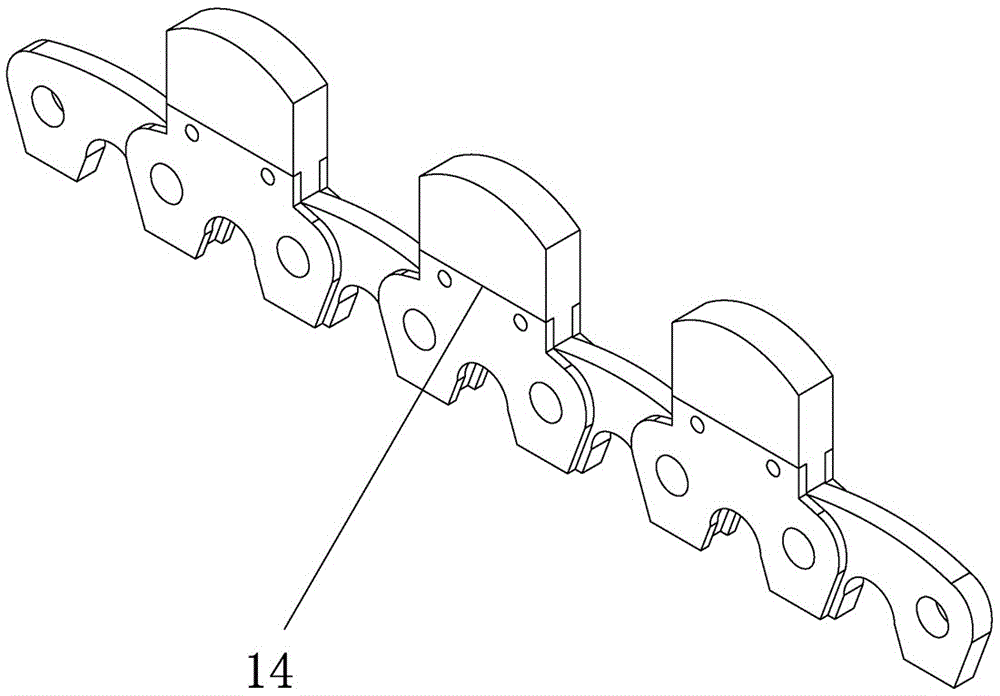

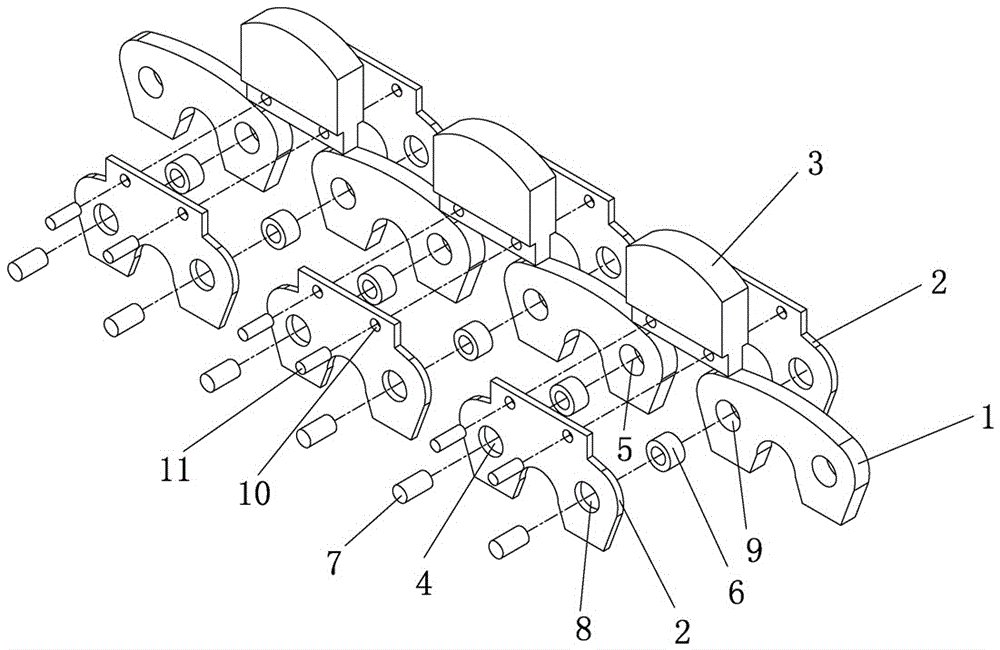

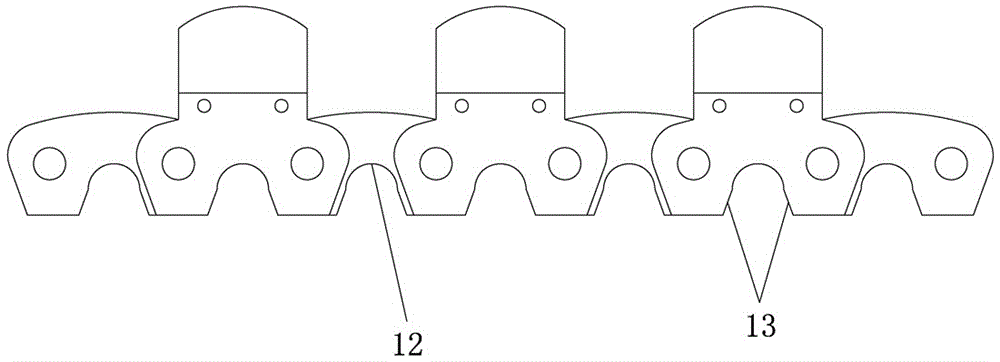

[0019] A kind of chain saw matched with the toothless sprocket on the stone cutting machine according to the present invention, such as figure 1 As shown in -8, it includes an inner chain piece 1, an outer chain piece 2, a cutter head 3, two front and rear outer chain pieces 2 clamp the left and right inner chain pieces 1, and the left mounting holes 4 of the front and back two outer chain pieces are connected to the The right mounting hole 5 of one inner chain piece is connected through the bushing 6 and the pin shaft 7, and the right mounting hole 8 of the front and rear outer chain pieces is connected with the left mounting hole 9 of the other inner chain piece through the bushing 6 and the pin shaft 7 Be provided with cutter head installation hole 10 at outer chain sheet 2 upper ends, the cutter head installation hole 10 of front and back two outer chain sheets 2 and the cutter head installation hole of cutter head 3 bottoms are connected through small pin shaft 11 tight fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com