High-speed paper cup (bowl) forming machine

A technology for forming machines and paper cups, applied in carton/carton manufacturing machinery, papermaking, paper/cardboard containers, etc., can solve the problems of slow paper feeding speed and limit the speed-up of high-speed paper cup forming machines, so as to improve the paper feeding speed and highlight the effect of substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

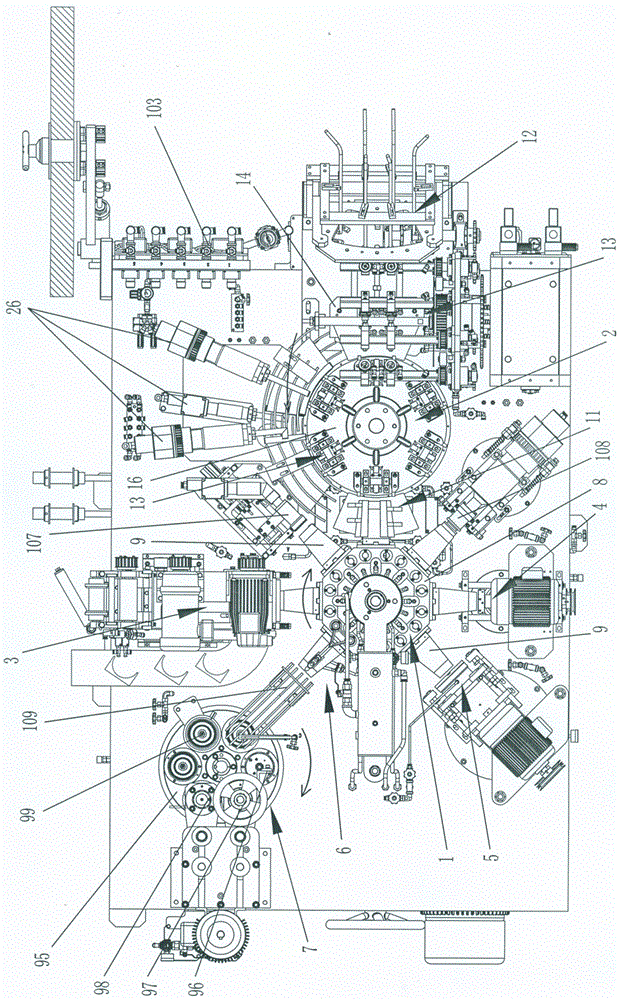

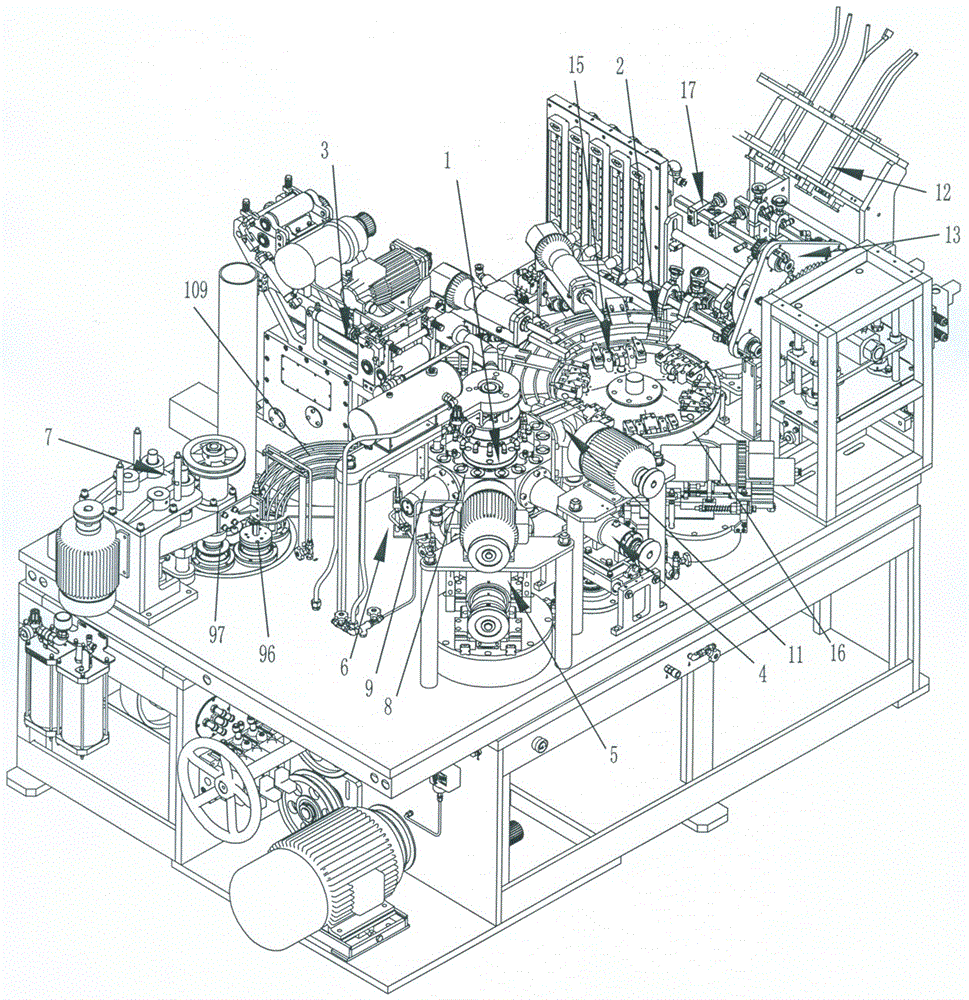

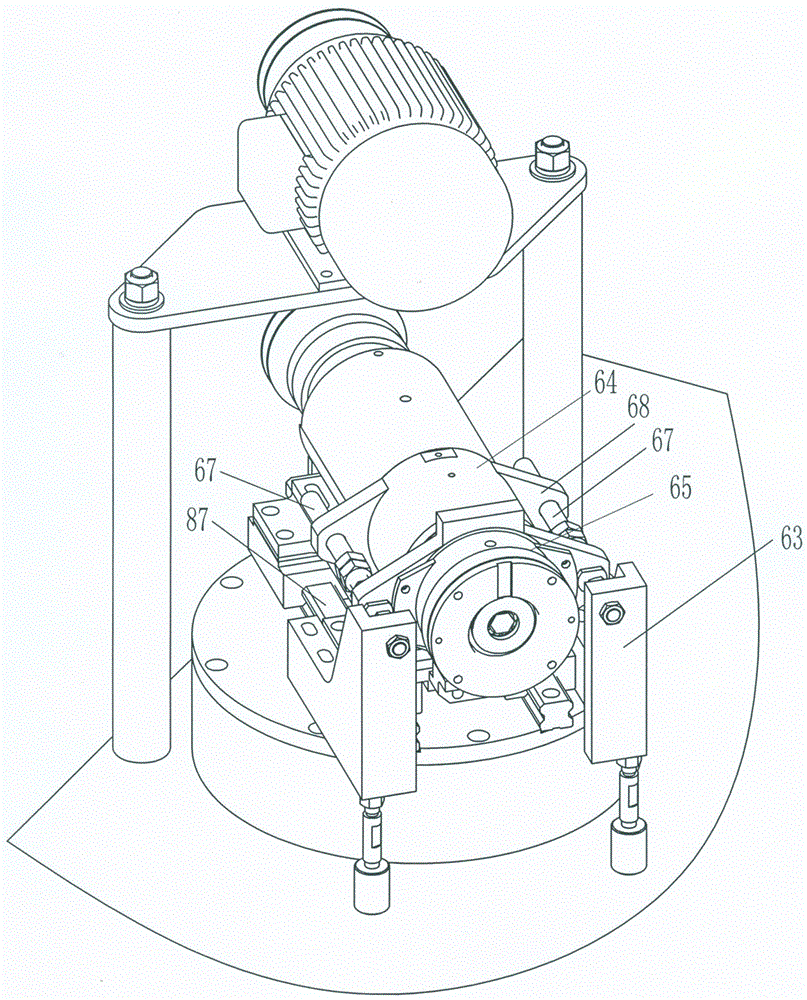

[0034] Referring to the accompanying drawings, the high-speed paper cup (bowl) forming machine in this embodiment includes a horizontal cup mold turntable mechanism 1, a rotary paper feeding mechanism 2, a bottom forming device 3, a roll bottom forming device 4, a knurling device 5, a Die mechanism 6 and mouth rolling mechanism 7. The cup mold turntable 8 of the horizontal cup mold turntable mechanism 1 is indexed and rotated. In the figure, eight cup molds 9 are set on the cup mold turntable 8 to rotate intermittently in eight equal parts. The bottom paper of the cup mold 9 is placed horizontally towards the outside. The cup mold 9 is driven by the cup mold turntable 8 to pass through the upper bottom station, the first bottom paper heating station, the cup body into a cone tube station, the second bottom paper heating station, the rolling bottom station, the knurling station, and the empty station and demoulding station. Bottom forming device 3 is set at the upper bottom st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap