Omnidirectional mobile platform

An omnidirectional mobile and platform technology, applied in the direction of motor vehicles, tire tread/tread pattern, tire parts, etc., can solve the problems of low reliability, unusable tires, and high-level environment, and meet the requirements of small size , increase the achievable range, and increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

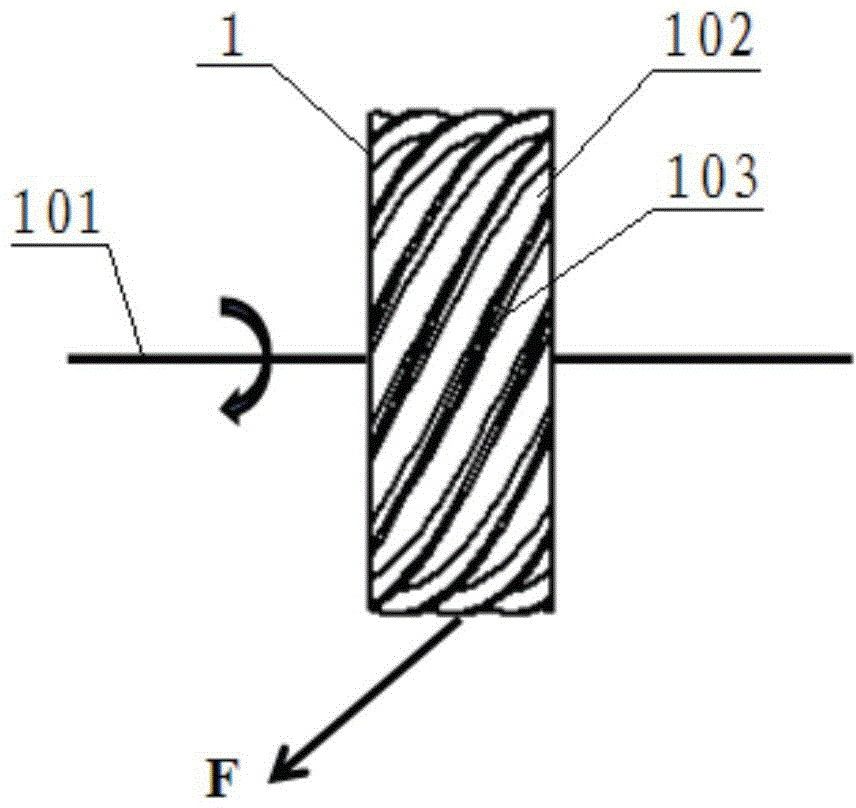

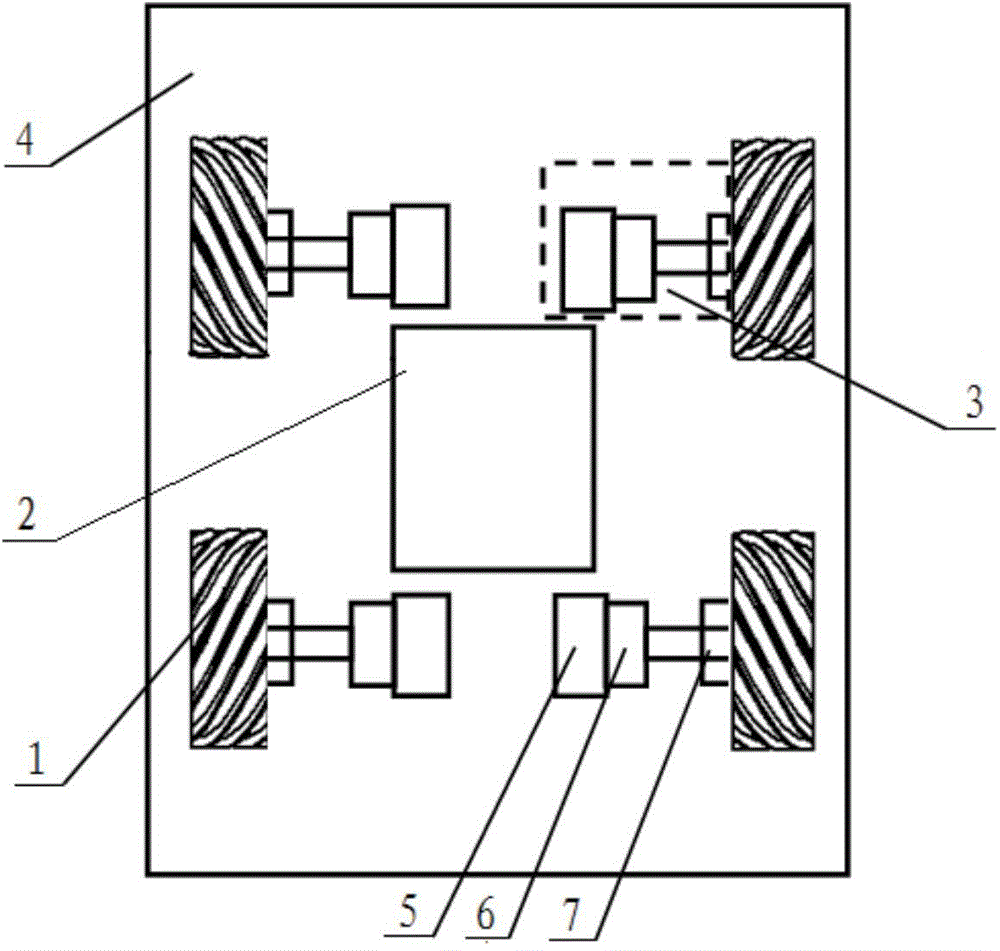

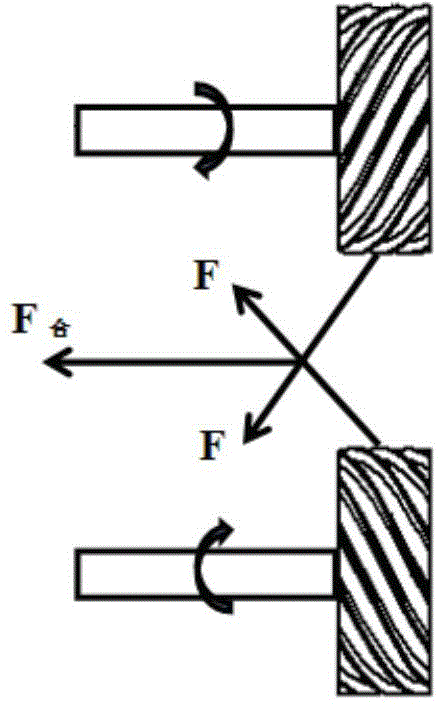

[0025] like figure 1 , figure 2 As shown, the present invention includes a wheel 1, a motion control unit 2, a motion execution unit 3 and a platform base 4, wherein the motion control unit 2 is arranged above the platform base 4, and the lower part of the platform base 4 passes through four motion execution units respectively. 3. Four wheels 1 are installed, each motion execution unit 3 is connected with the motion control unit 2, and the tire tread of the wheels 1 is provided with twill.

[0026] The diagonal pattern on the tire tread of the wheel 1 includes a plurality of inclined grooves 102 and a plurality of inclined blocks 103 inclined in the same direction, and the inclined grooves 102 and the inclined blocks 103 are alternately arranged at intervals and are parallel to each other. The angle between the inclined groove 102 and the inclined block 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com