Rotary clamping structure for half shaft

A semi-circular, installation groove technology, applied in the direction of internal accessories, etc., can solve the problems of easy damage of foam, increased cost, unfavorable multiple use, etc., to achieve the effect of ensuring the quality of delivery, reducing bumps, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

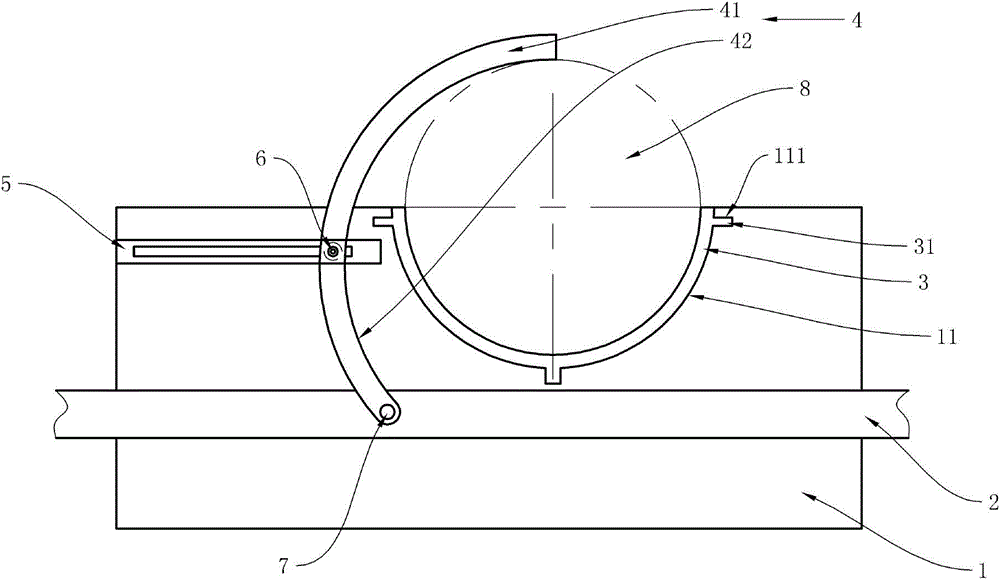

[0013] see figure 1 , a half-shaft rotation clamping structure, including a base 1, the base 1 is provided with a semicircular mounting groove 11, and the mounting groove 11 is also provided with a fixing groove 111;

[0014] The engaging half-ring 3 is loaded into the installation groove 11 and the locking protrusion 31 arranged on the engaging half-ring 3 is put into the fixing groove 111;

[0015] The base 1 is also provided with a mounting plate 5, the mounting plate 5 has a mobile mounting groove, and the curved pressing plate 4 is installed on the mounting plate 5 through the first hinge 6;

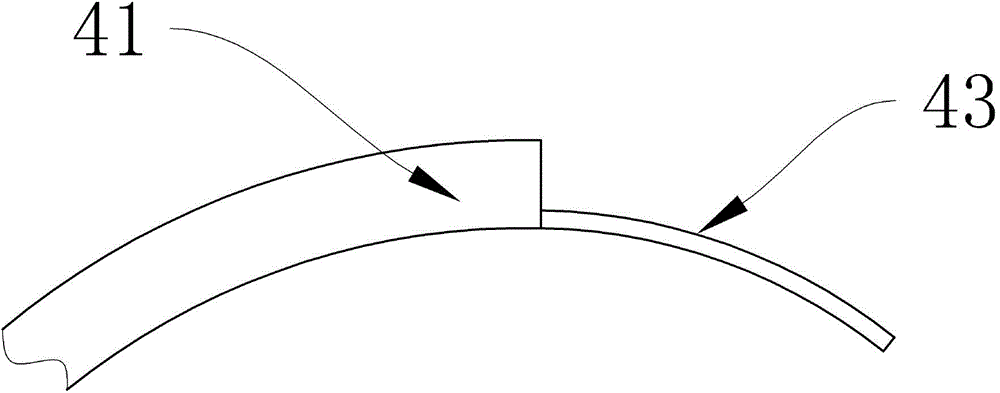

[0016] The curved pressure plate 4 includes a compression section 41 and a stressed section 42, the curvature of the compressed section 41 is smaller than that of the stressed section 42, and the stressed section 42 is hinged to the push-pull plate 2 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com