Cosmetic box body rotary conveying mechanism

A technology of rotary conveying and cosmetics, which is applied in liquid bottling, liquid treatment, transportation and packaging, etc. It can solve the problems of poor production line, low efficiency, manual handling, etc., and achieve improved filling effect, high efficiency, and good handling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

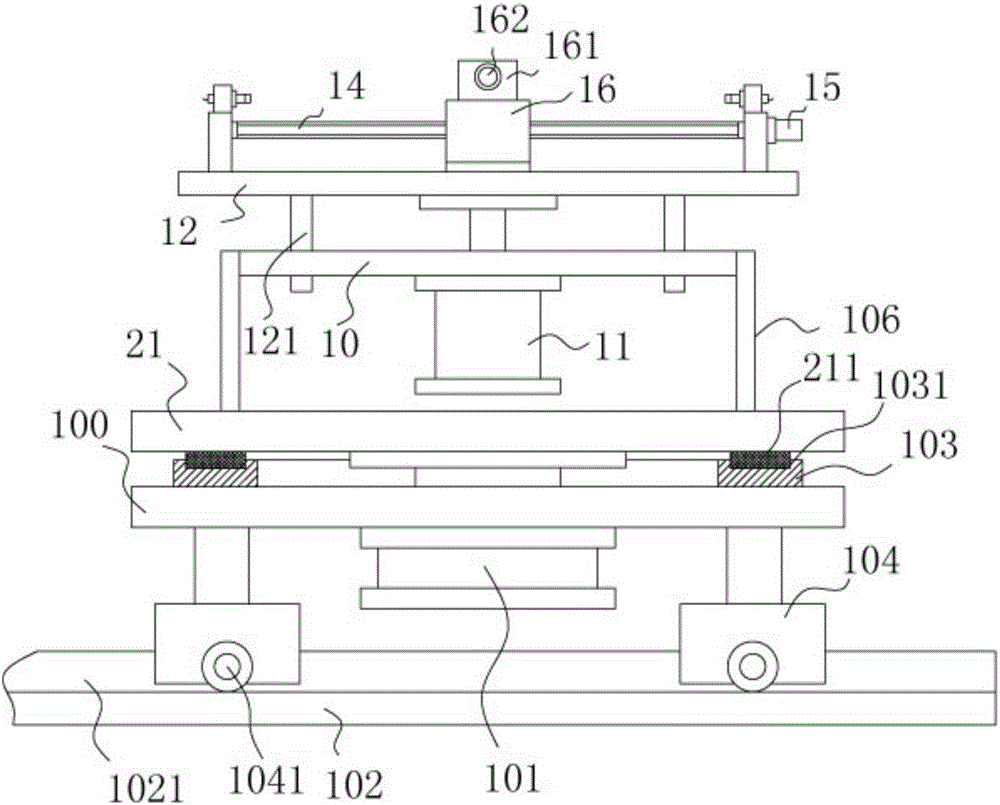

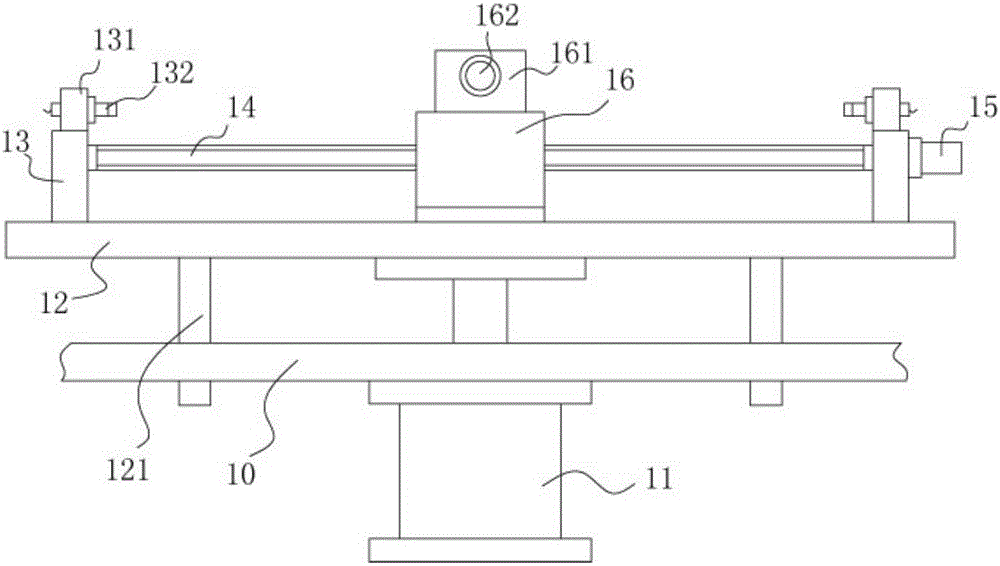

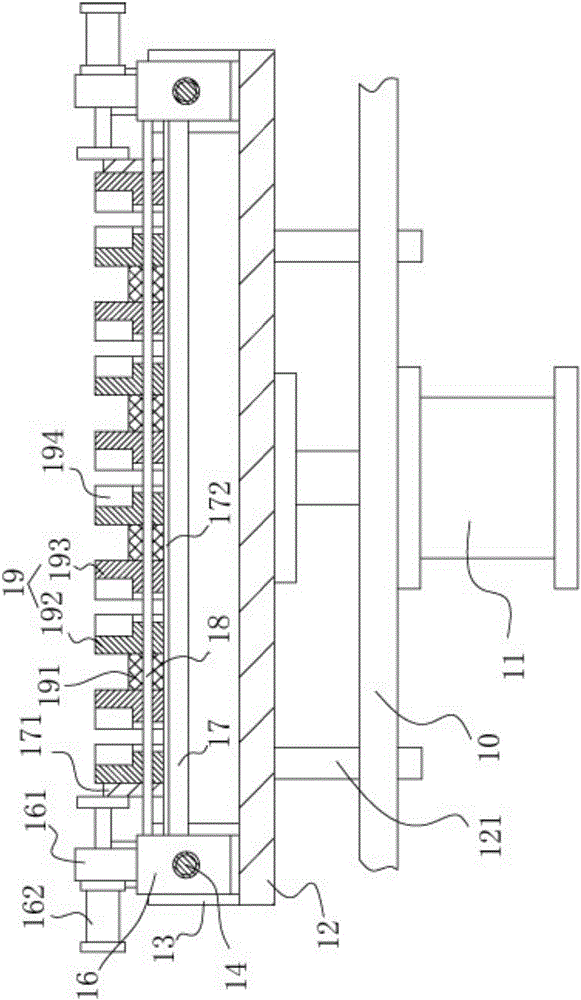

[0019] Example: see Figure 1 to Figure 4 As shown, a cosmetic box rotary conveying mechanism includes a frame 100, a servo motor 101 is fixed in the middle of the bottom surface of the top plate of the frame 100, a guide rail 102 is fixed on the bottom surface, and the rotating shaft of the servo motor 20 extends out of the frame upwards. The top plate of 100 is fixed with a rotating support plate 21, the bottom leg of the frame 100 is fixed with a sliding block 104, the bottom surface of the sliding block 104 has a chute 105, and the top surface of the guide rail 102 has an upwardly extending extending raised bar 1021, The extended protruding bar 1021 is inserted and sleeved in the chute 105, and the outer side wall and the top surface of the extended protruding bar 1021 are fixed with a self-lubricating wear-resistant layer, and the self-lubricating wear-resistant layer is pressed against the inner wall of the chute 105, and the sliding block The outer wall of 104 is hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com