A kind of stretched sheath-core untwisted composite filament and its production method and application

A composite filament, skin-core technology, applied in the direction of conjugated synthetic polymer artificial filament, separation method, filament/thread forming, etc., can solve the problems of human and environmental damage, irritating odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

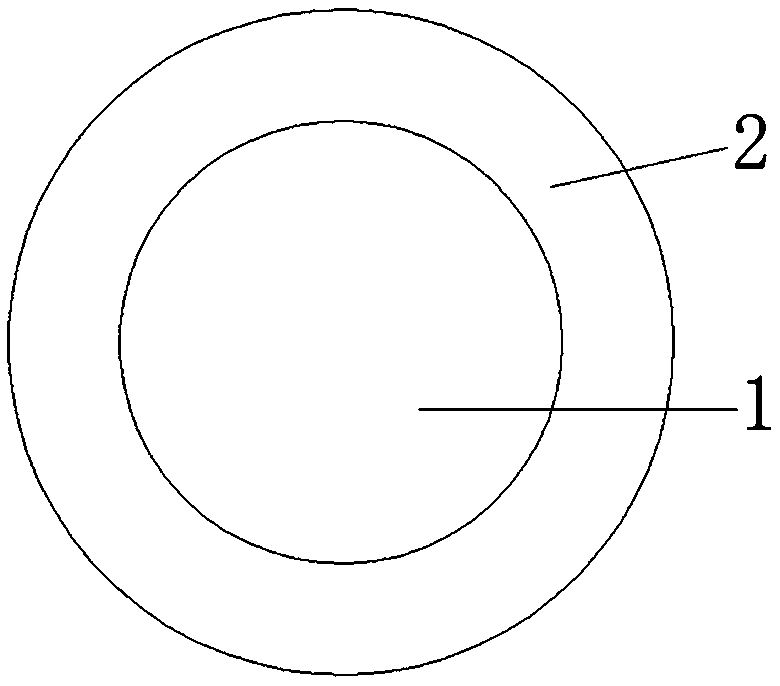

[0028] Refer to attached figure 1 , a stretched skin-core untwisted composite filament is composed of a skin layer 2 and a core layer 1, the skin layer 2 is wrapped outside the core layer 1, the core layer component is polyester (PET), and the skin layer 2 component is a modified low melting point Polyester (PET) or polypropylene (PP) material, the melting point of the skin layer 2 is 150-210 degrees, and the melting point of the core layer 1 is 250-260 degrees.

[0029] For the stretched sheath-core untwisted composite filament, the ratio of the second component of the skin layer is 20-40%, and the ratio of the first component of the core layer is 80-60%.

[0030] The textured sheath-core untwisted composite filament is characterized in that: the material of the skin layer 2 is modified high-crystallization low-melting point polyester PET, which can meet the requirements of texturing.

[0031] The fineness range of the stretched sheath-core untwisted composite filament is 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com