Profiled composite fiber free from heat bonding and heat setting with adhesive and production method and application thereof

A composite fiber, thermal bonding technology, used in fiber processing, conjugated synthetic polymer rayon, stretch spinning, etc., can solve problems such as human and environmental damage, irritating odors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

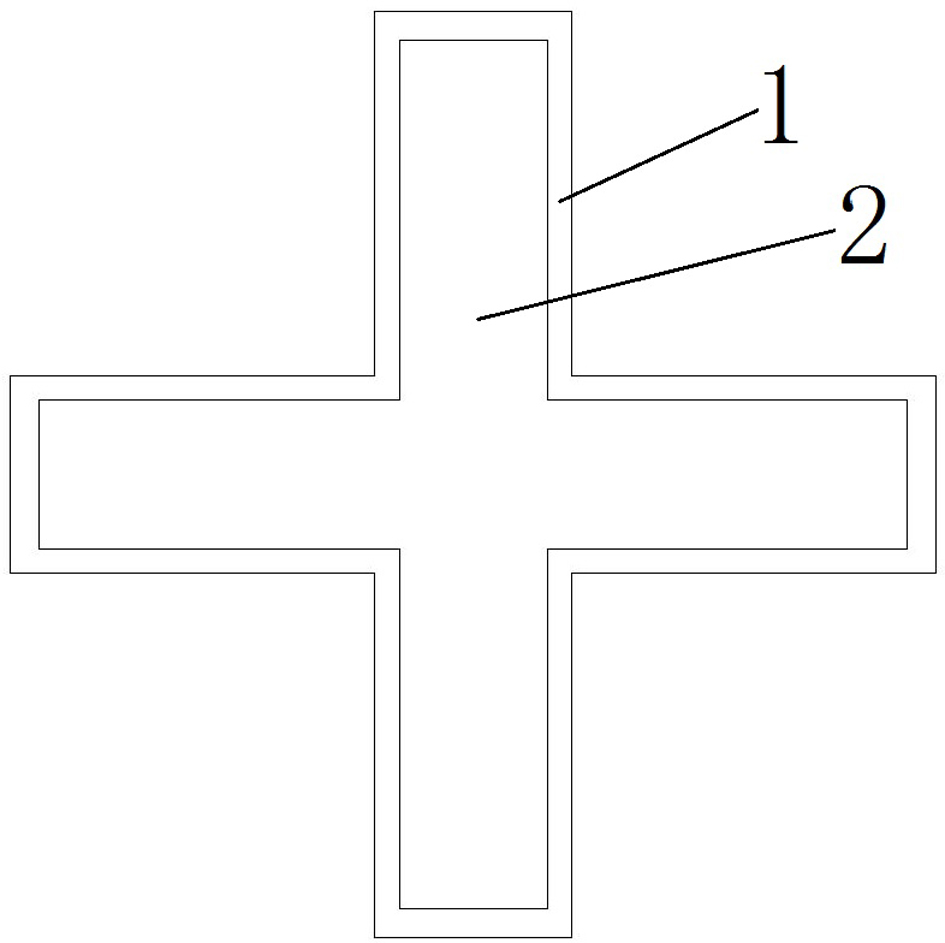

[0075] Embodiment 1: a kind of production method of glue-free heat-bonded shaping special-shaped composite fiber,

[0076] The present invention is carried out on twin-screw composite spinning equipment and double-twist direction texturing machine, and the whole production process steps are as follows:

[0077] 1. Modification of raw materials for special-shaped skin layer 1. The general modified low-melting point polyester PET on the market cannot be elasticized. The low-melting point polyester PET must be re-modified and made by adding nucleating agent PPT plastic raw materials. The nucleating agent is re-modified and can crystallize quickly, and then the raw material is dried at a drying temperature of 80-100 degrees and a drying time of 8-12 hours. The water content is less than 50PPM.; the added amount of the nucleating agent PPT plastic raw material accounts for 5-20% of the total cortex raw material.

[0078] 2. Crystallize and dry the material of the special-shaped co...

Embodiment 2

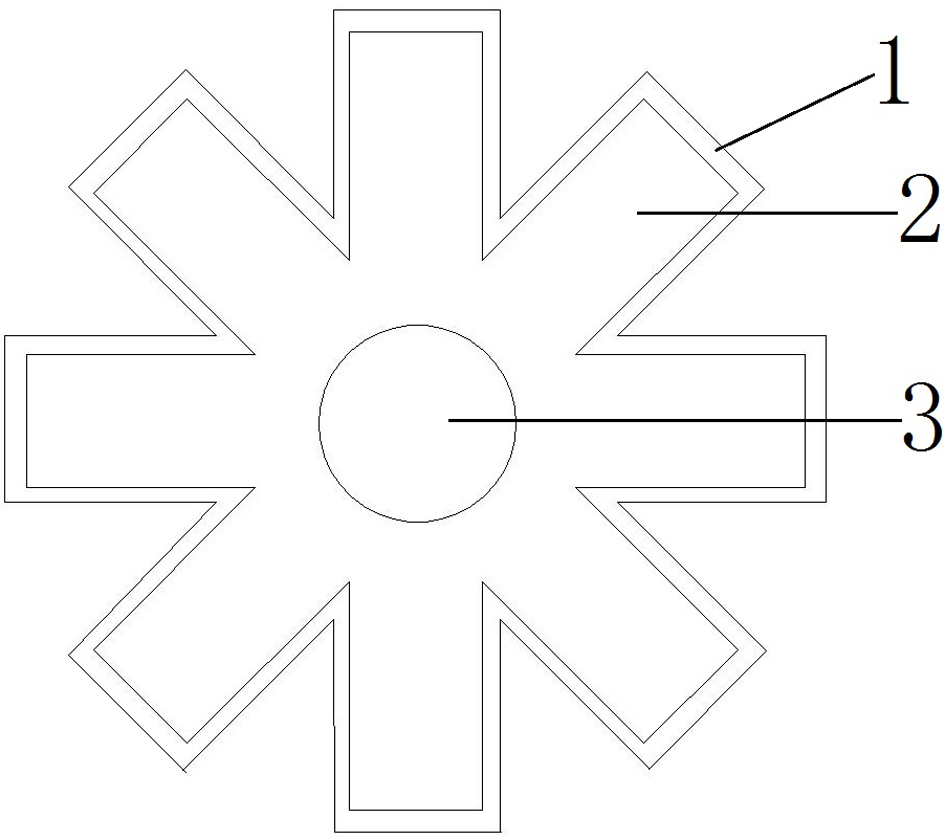

[0084] Embodiment 2: Another production method of glue-free heat-bonding shaped special-shaped composite fiber,

[0085] The present invention is carried out on twin-screw composite spinning equipment and double-twist direction texturing machine, and the whole production process steps are as follows:

[0086] 1. Modification of raw materials for special-shaped skin layer 1. The general modified low-melting point polyester PET on the market cannot be elasticized. The low-melting point polyester PET must be re-modified and made by adding nucleating agent PPT plastic raw materials. The nucleating agent is re-modified and can crystallize quickly, and then the raw material is dried at a drying temperature of 80-100 degrees and a drying time of 8-12 hours. The water content is less than 50PPM.; the added amount of the nucleating agent PPT plastic raw material accounts for 5-20% of the total cortex raw material.

[0087] 2. Crystallize and dry the material of the special-shaped core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com