Driving device of water jet loom

A driving device and loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of easy corrosion of accessories, failure of accessories, high frequency of replacement, etc., achieve less workmanship, prolong service life, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

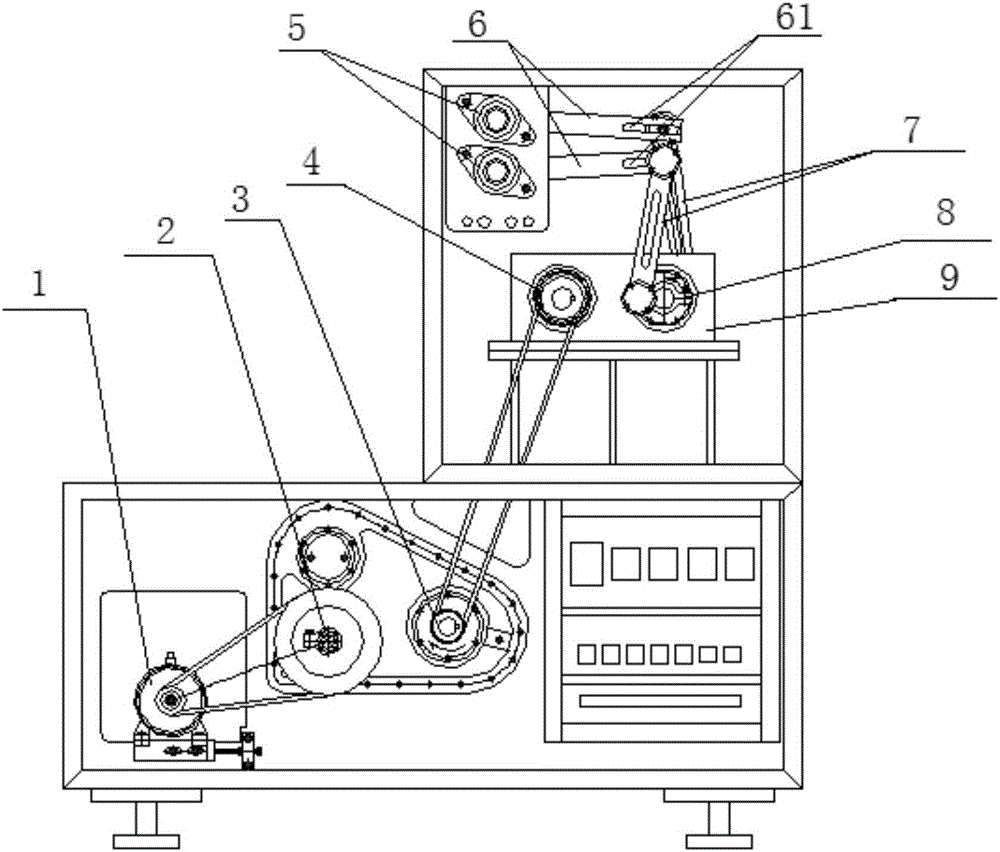

[0017] refer to figure 1 , the driving device of the water jet loom of the present embodiment, which includes a driving motor 1, a crankshaft 2, a gear 3, a gearbox 9, a connecting rod I6, a connecting rod II7, a bearing with a seat 5, and the gearbox 9 is arranged on the weaving On the side above the machine, the gearbox 9 includes a transmission shaft 4 and a turntable 8, the transmission shaft 4 and the turntable 8 are connected through a connecting rod, the driving motor 1 is connected with the crankshaft 2 through a synchronous belt, the crankshaft 2 is connected with the gear 3, and the gear 3 is connected through a synchronous The belt is connected to the drive shaft 4, and there are two connecting rods I6, II7, bearings with seats 5, and turntables 8. The two turntables 8 are coaxially arranged on both sides of one end of the gearbox 9, and one end of the two connecting rods II7 is They are respectively arranged on the two turntables 8, and the other ends are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com