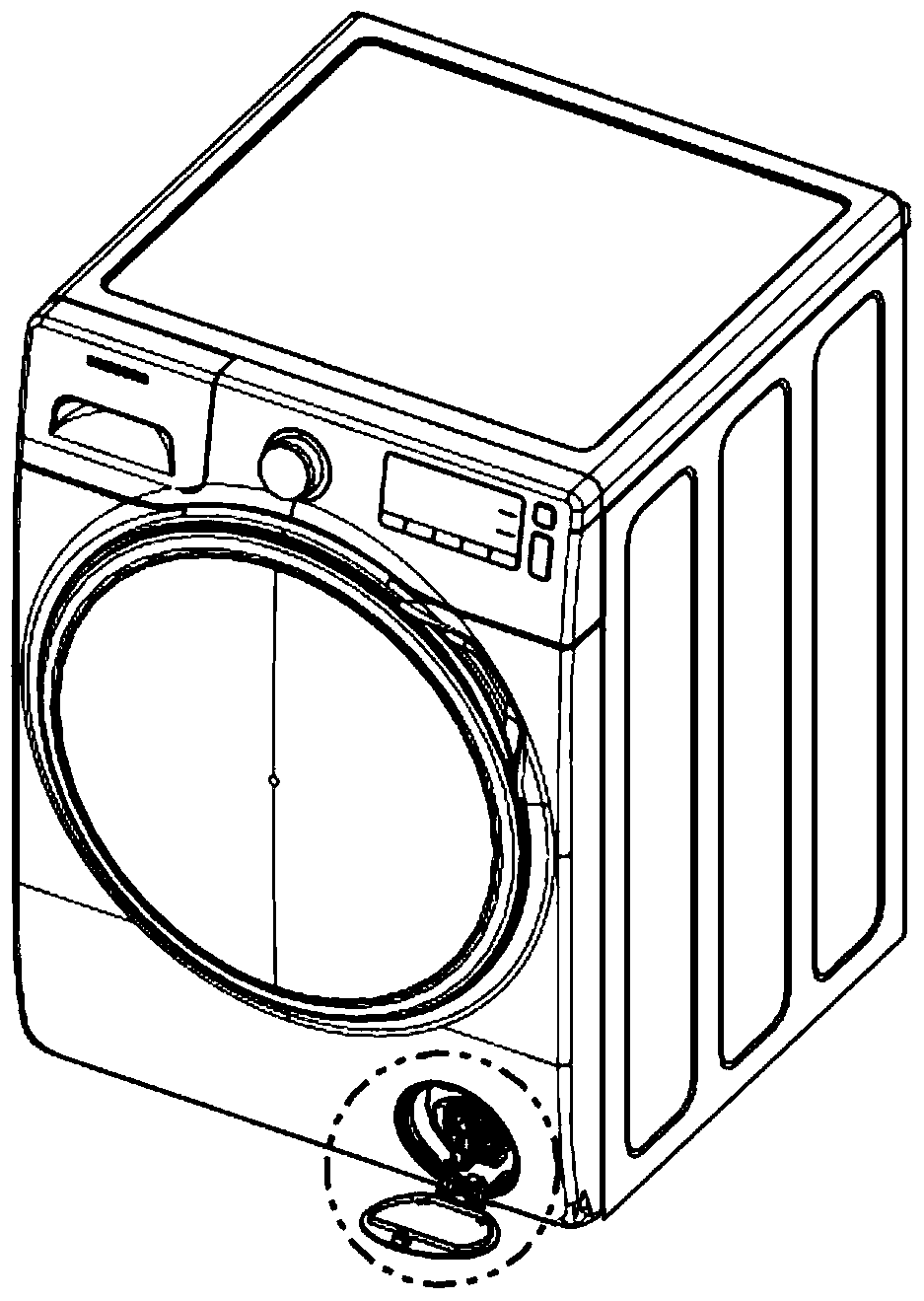

A washing machine drainage pump cover support structure

A support structure and drainage pump technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of difficult production and assembly of the rotating shaft 5 and the circular tank 4, increased maintenance, use costs, difficult maintenance and disassembly, etc., to achieve Easy to switch, reduce maintenance and use costs, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

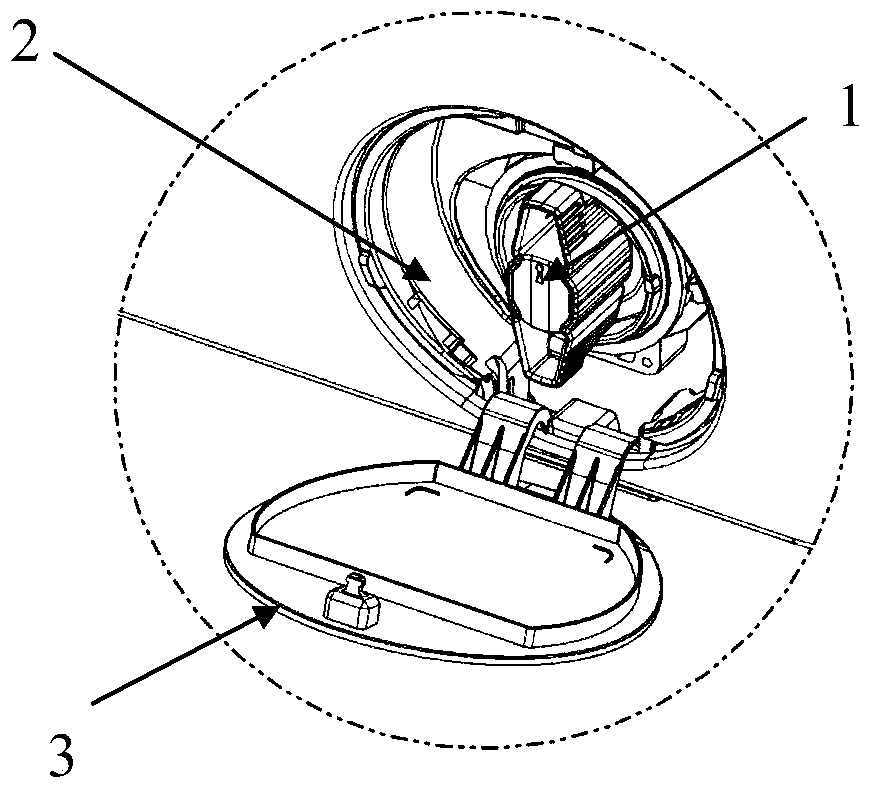

[0028] The lower side of the washing machine in the current market has a cover plate structure that blocks the drain pump, and the cover plate realizes the switch function by cooperating with the cover plate bracket. The cooperation between the cover plate and the cover plate support is usually a shaft structure. The rotating shaft structure is easy for users to switch on and off, but the production and assembly of the rotating shaft and the circular groove are difficult, and it is difficult to disassemble after-sales maintenance. The disassembly process is easy to damage the structure and increase maintenance and use costs.

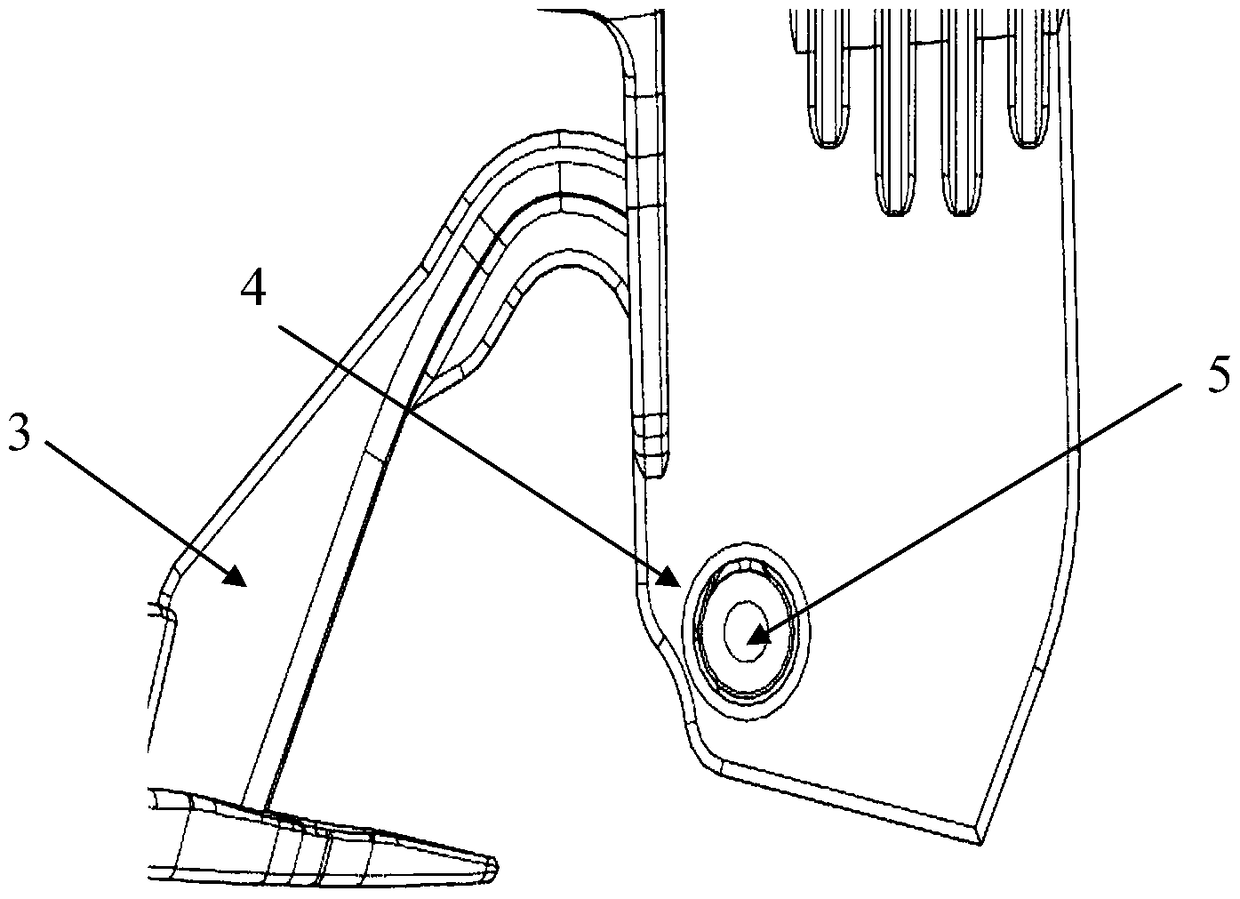

[0029] Aiming at the deficiencies in the prior art, the present invention provides a support structure for the cover plate of the washing machine drainage pump. Through the cooperative connection between the slide rail groove and the rotating shaft, the detachable fixing of the cover plate is realized. By designing a protrusion inside the slide rail groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com