A wall bushing with removable transport supports

A technology of wall-piercing sleeves and support seats, which is applied in pipes, climate sustainability, sustainable packaging, etc., and can solve the problems of heavy on-site installation preparation, poor product safety and reliability, and large gas consumption. Achieve the effects of reducing the amount of insulating gas, easy processing, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

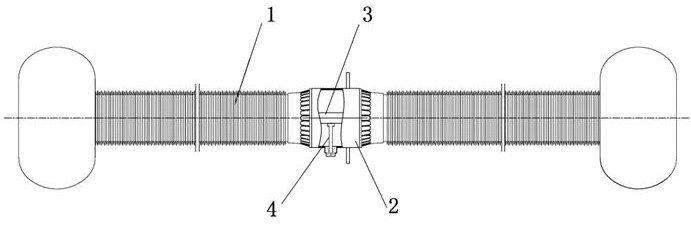

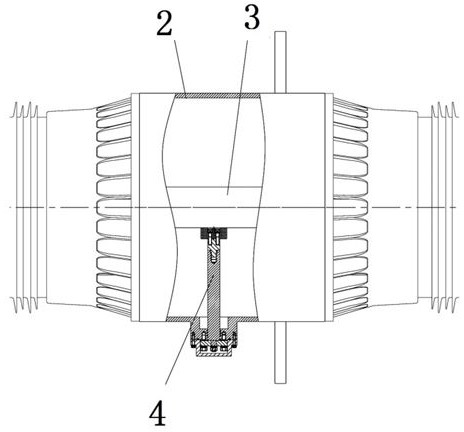

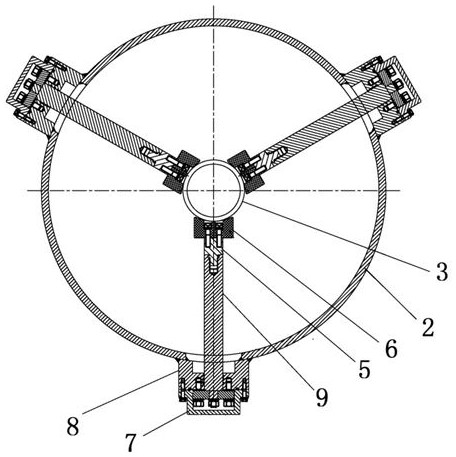

[0048] The wall bushing of the present invention using detachable transport supports, such as Figure 1-Figure 2 As shown in the figure, its basic structure is the same as that of the wall bushing in the prior art, including an insulating jacket 1 on both sides and a cylinder 2 connected between the two insulating jackets 1. The inside of the cylinder 2 and the insulating jacket 1 forms a closed inner casing. A conductive rod 3 is installed in the closed cavity, and the closed cavity is filled with SF as an insulating gas. 6 .

[0049] Because the deformation of the conductive rod 3 is easily aggravated by bumping and vibration during transportation, and may break in severe cases, affecting subsequent normal use. The present invention innovates on the basis of the existing wall-penetrating bushings, and a support structure is arranged on the cylinder body 2. The support structure includes a fixed seat on the cylinder body and a support rod 4, and the fixed seat is provided wi...

specific Embodiment 2

[0058] The difference from Embodiment 1 is that the support seat is one piece and made of metal material.

specific Embodiment 3

[0060] Different from Embodiment 1, the side of the fixing seat facing the inside of the cylinder is flush with the inner wall of the cylinder, which is an arc surface. Correspondingly, the surface on the insulating seat that is used for contact and matching with the fixing seat is also an arc surface. , when the support seat is connected and matched with the fixed seat, the insulating seat protrudes inward along the inner cylinder wall of the cylinder. In this embodiment, the inner end of the rod is connected with the connecting joint in the following manner: the inner end of the rod is provided with an axial hole, the peripheral surface of the inner end of the rod is provided with a radial hole that communicates with the axial hole, and the connecting joint is provided with a diameter For radial threaded holes that match the holes, when the rod body is connected with the connecting joint, insert the connecting joint into the axial hole at the inner end of the rod body, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com