Mobile launching site

A technology of launch site and roof, applied in the direction of roads, special pavements, roads, etc., can solve problems such as difficulty, fracture, weak bearing capacity, etc., and achieve the effect of easy installation, maintenance and replacement, simplification of connection structure, and enhancement of load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

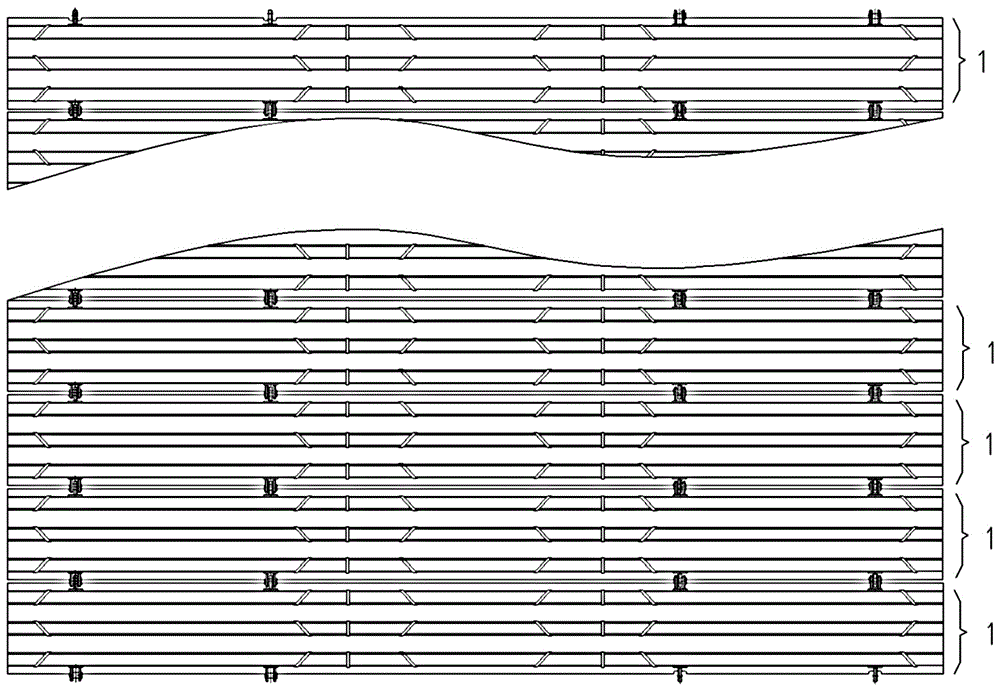

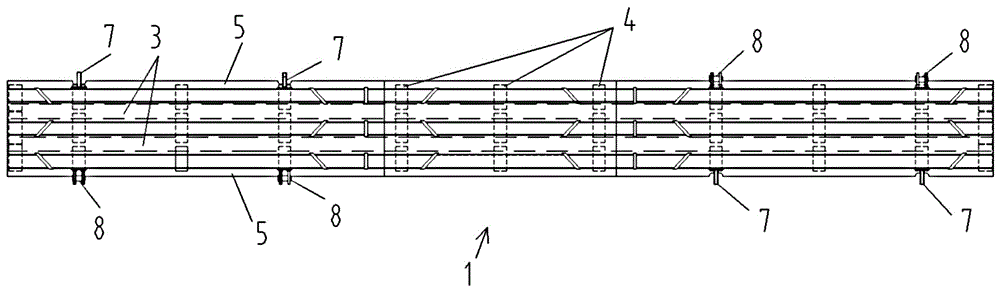

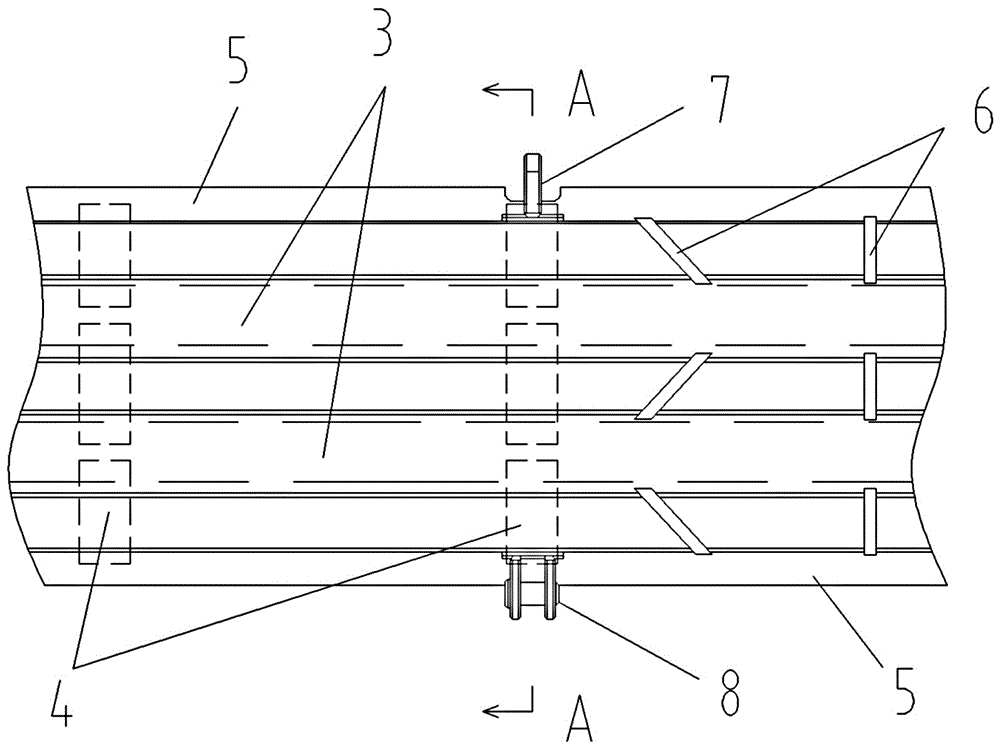

[0019] Such as figure 1 As shown, the present invention provides a kind of mobile launching site platform, comprises a group of interconnected road panel units 1, combines Figure 2~4 As shown, the road panel unit 1 includes a top plate 2, and the top plate 2 is in the wave shape of three peaks and two valleys, and the peaks and valleys are both flat; the bottom of the top plate 2 is provided with a U-shaped groove 3 along the axial direction, and the present invention uses Two U-shaped tanks, the opening of the U-shaped tank 3 is connected to the top plate 2, and the opening of the U-shaped tank 3 is matched with the valley of the top plate 2; there is also a reinforcement seat array 4 under the top plate 2, and the reinforcement seat array 4 It is composed of a group of reinforcing seats 4a distributed along the axial and radial directions of the top plate 1 respectively. In this embodiment, three rows of reinforcing seats are provided, combined with Figure 5-7 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com