Track cable pulling and supporting start-stop system

A technology of rails and rails, applied in the field of rail rope traction support opening and closing systems, can solve the problems of long technical clearance, long wasted time, inability to erect bridges on water or canyons, etc., and achieves simple and convenient process and fast construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

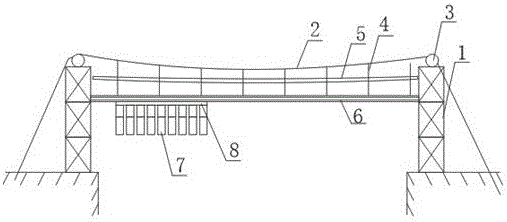

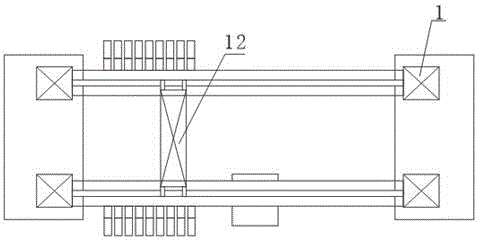

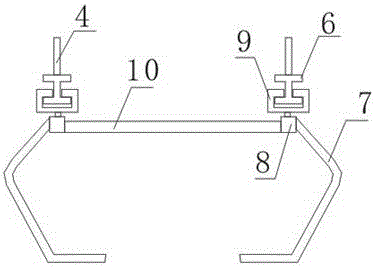

[0025] Embodiment 1: see Figure 1 to Figure 4 , a track cable traction support opening and closing system, including two sets of support frames 1, each group is two, respectively located at the two ends of the bridge erection place, each set of support frames 1 is provided with a main rope body 2, and the main rope body 2 The two ends are anchored on the ground after passing through the top of the support frame 1. The two main rope bodies 2 are parallel to each other. There is a catwalk 5 under the main rope body 2, and a track 6 is connected to the bottom of the main rope body 2 through a suspension rope 4. The track 6 is arranged along the length direction of the main rope body 2, the two rails 6 are located on the same horizontal plane and parallel to each other, and a formwork system is provided under the two rails 6, and the formwork system includes a beam 8 and several formwork support systems suspended below the beam 8 7;

[0026] The two rails 6 are provided with sli...

Embodiment 2

[0029] Example 2: see Figure 5 , a track cable traction support opening and closing system, including two sets of support frames 1, each group is two, respectively located at the two ends of the bridge erection place, each set of support frames 1 is provided with a main rope body 2, and the main rope body 2 The two ends are anchored on the ground after passing through the top of the support frame 1. The two main rope bodies 2 are parallel to each other. There is a catwalk 5 under the main rope body 2, and a track 6 is connected to the bottom of the main rope body 2 through a suspension rope 4. The track 6 is arranged along the length direction of the main rope body 2, the two rails 6 are located on the same horizontal plane and parallel to each other, and a formwork system is provided under the two rails 6, and the formwork system includes a beam 8 and several formwork support systems suspended below the beam 8 7;

[0030] The track 6 is provided with several slide rail boxe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com