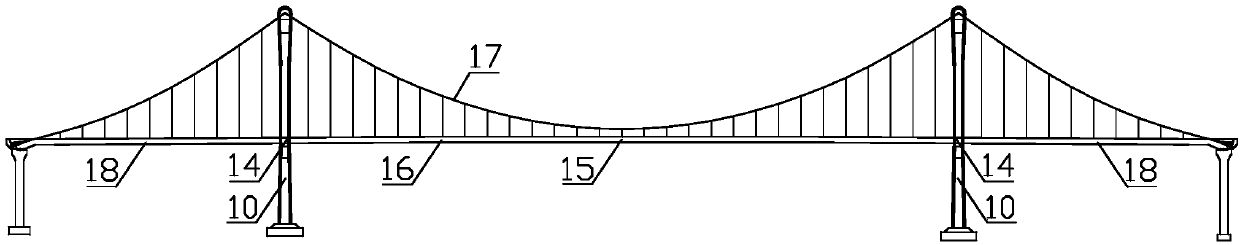

The System Transformation Method of Construction of Self-anchored Suspension Bridge with Cables First and Beams Later

A self-anchored suspension bridge and system conversion technology, applied in suspension bridges, bridges, bridge construction, etc., can solve problems such as closing gaps, eliminate construction errors and temperature, improve conversion stability, and ensure the effect of high precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

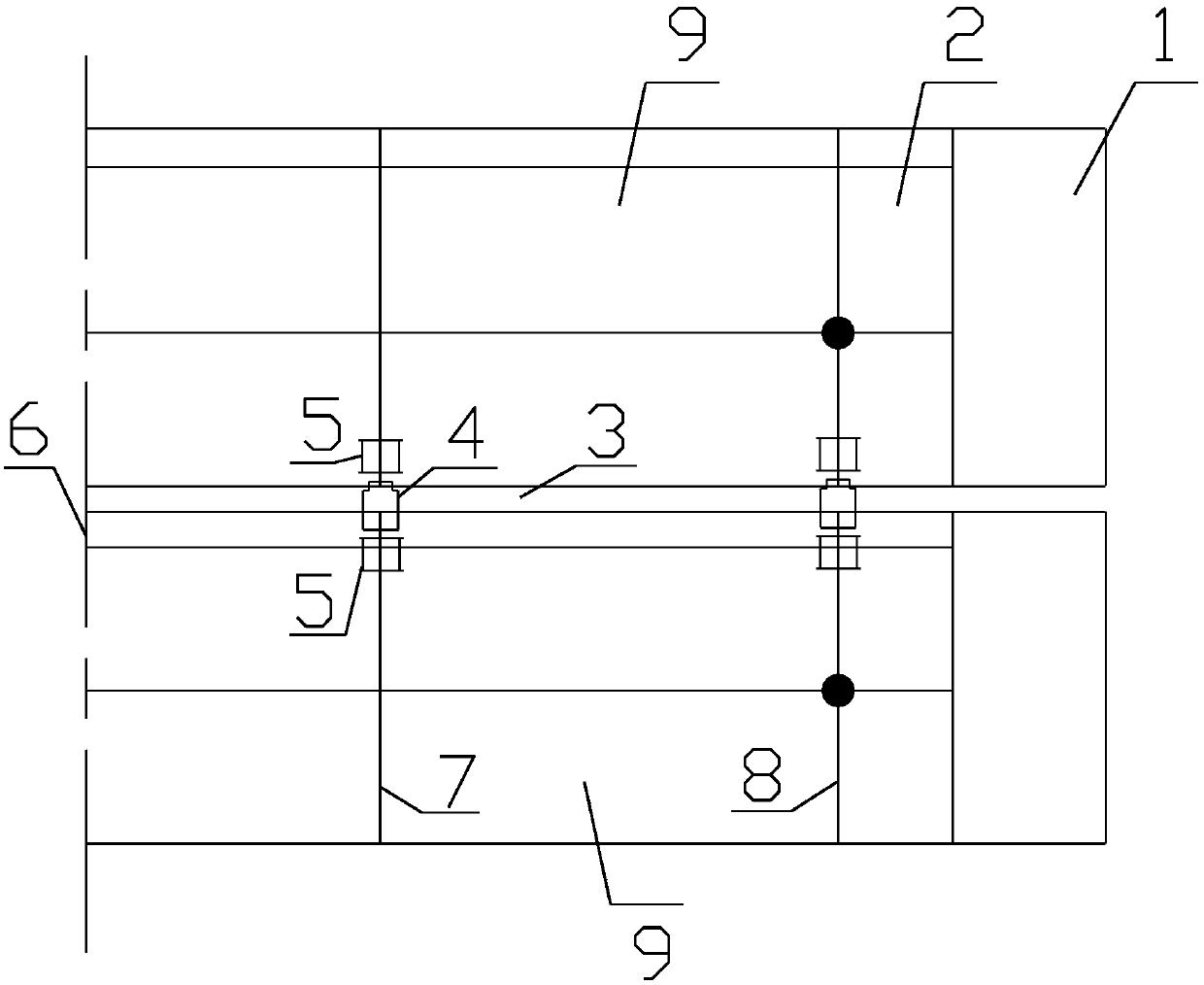

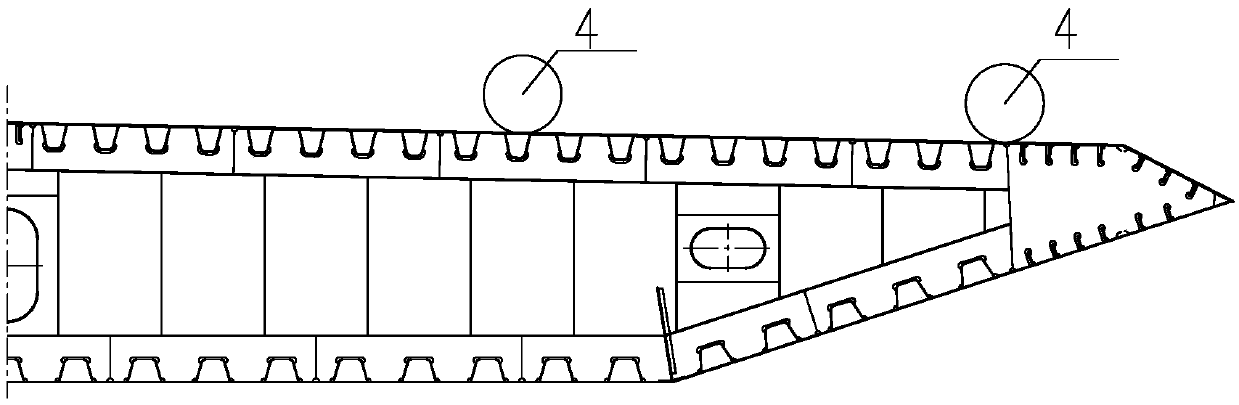

[0045] The East Tiaoxi Bridge fixes Helongkou 3 at the joint between the B6 beam section and the B7 beam section on the west side. Before closing, the remaining beam sections have completed the joint adjustment and girth welding. At this time, the horizontal tension of the main cable 17 to the side beam 18 is 1800t. Two 500t bridge tower jacks 12 are arranged in the temporary anchoring devices 14 for tower beams on both sides of each bank. One end of the main girder 16 contains two bridge towers 10, so one end of the main girder 16 has four 500t bridge tower jacks 12; A total of 12 sets of 500t Helongkou Jack 4 will be used for system conversion. The steps are as follows:

[0046] 1. Check whether all preparations are completed.

[0047] 2. Start the 4 Helongkou jacks 4 at 3 locations in Helongkou, each with a lifting force of 200t, a total of 800t, lock the cylinder, and take protective measures on both sides of the Helongkou jack 4. At this time, the temporary anchoring reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com