Gas jet flow type blue adding combined ejector and application thereof

A technology of gas jets and injectors, which is applied in the direction of liquid injection devices, injection devices, exhaust treatment, etc., can solve the problems of difficult design, high manufacturing cost, and complicated pipelines, so as to reduce the difficulty of closed-loop control, reduce risks, The effect of eliminating transmission delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

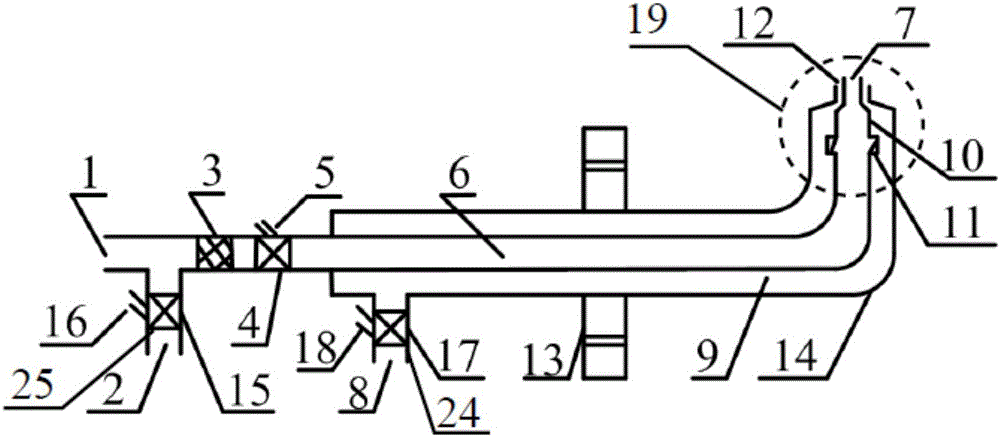

[0031] like Figure 1~3 As shown, the gas jet type adding blue combination injector designed by the present invention comprises a double-layer casing, and the double-layer casing includes a casing 14, and the outside of the casing 14 is provided with a mounting flange 13, and the mounting flange 13 is connected to the double-layer casing. Layer casings are made of stainless steel. The tube side of the double-layer casing is the Tianlan channel 6, the shell side of the double-layer casing is the compressed air channel 9, and the Tianlan channel 6 and the compressed air channel 9 are coaxial and isolated from each other.

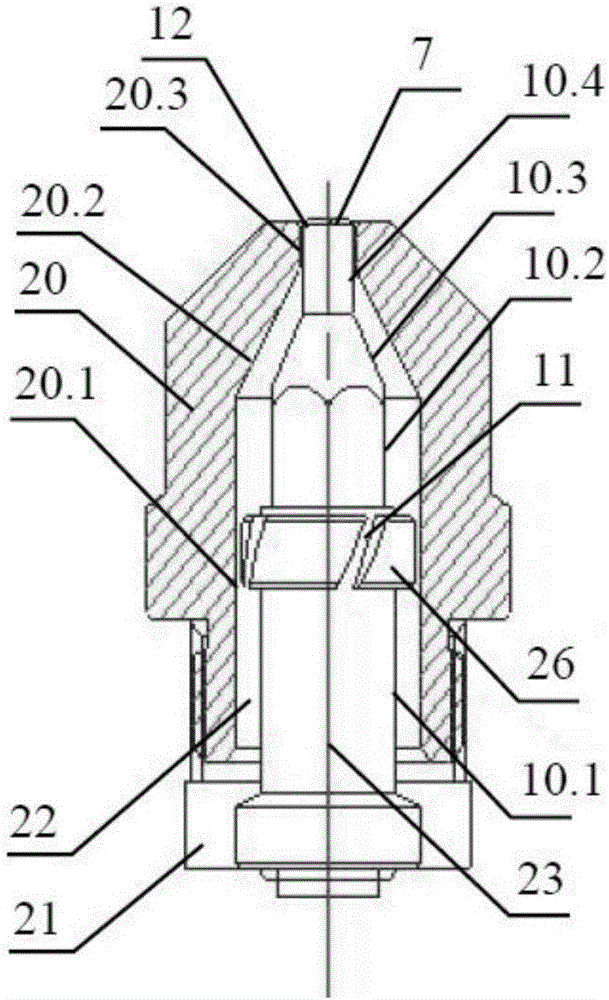

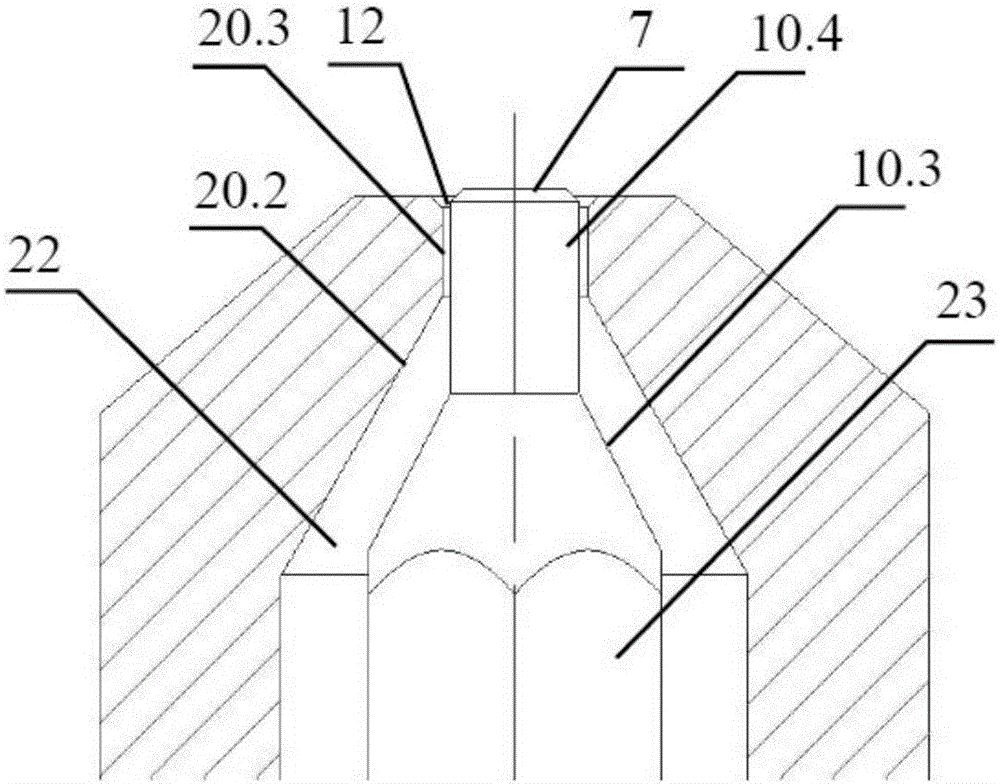

[0032] The front end of the double-layer casing is provided with a pneumatic nozzle 19. The pneumatic nozzle 19 includes a nozzle housing 20, a casing joint 21 and a swirl core 10. An annular nozzle gas phase channel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com