Integrated draught fan assembly

An integrated fan technology, applied to liquid fuel engines, pump components, components of pumping devices for elastic fluids, etc., can solve problems such as personal safety accidents, reduce material costs, eliminate potential safety hazards, and improve labor costs. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

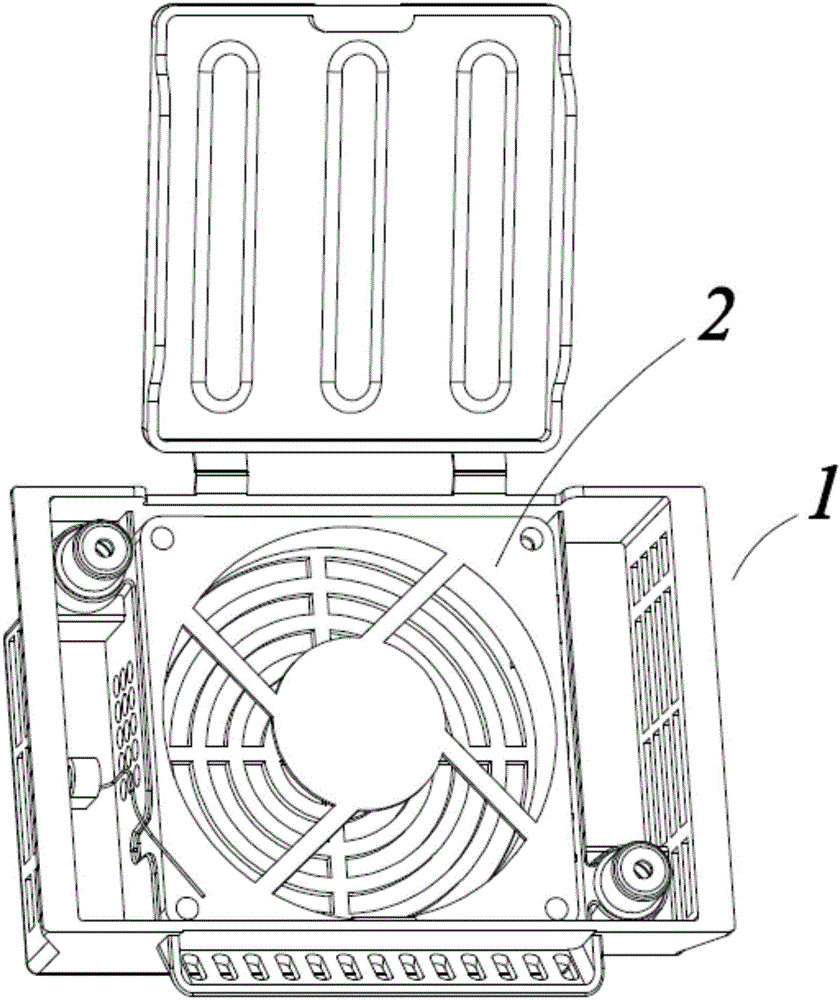

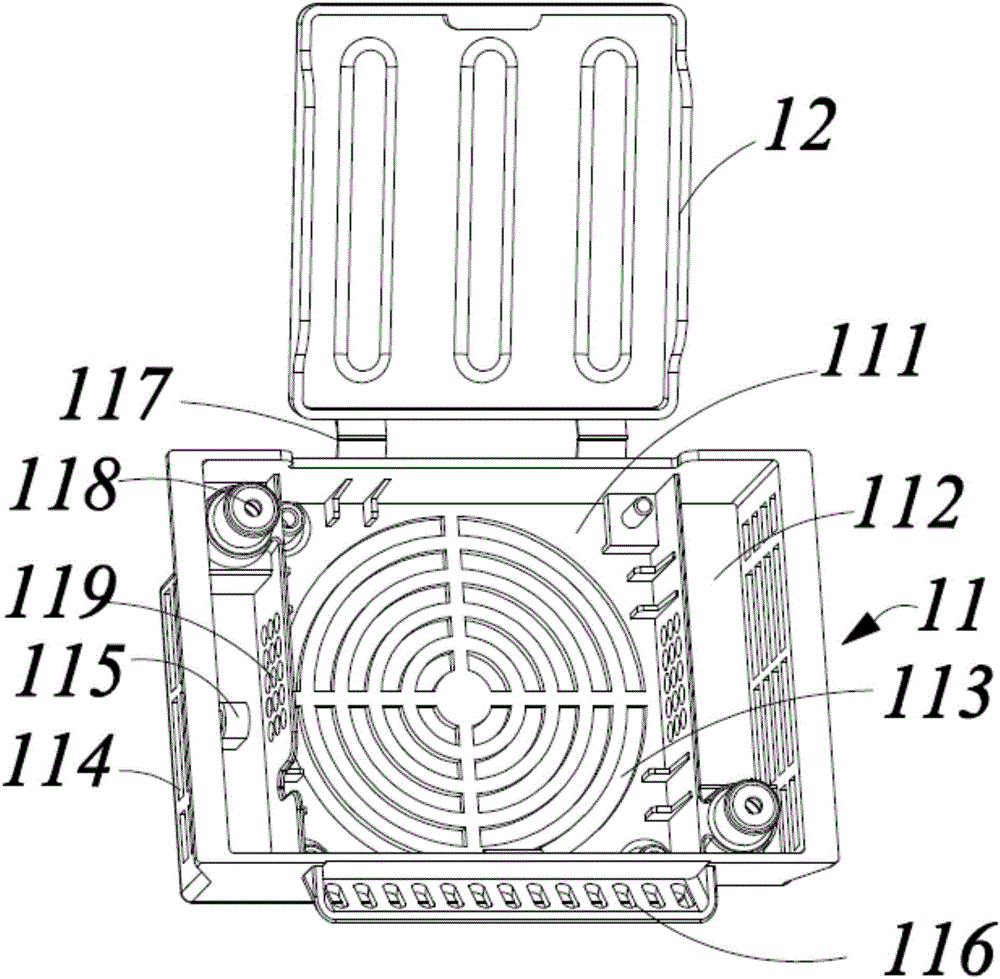

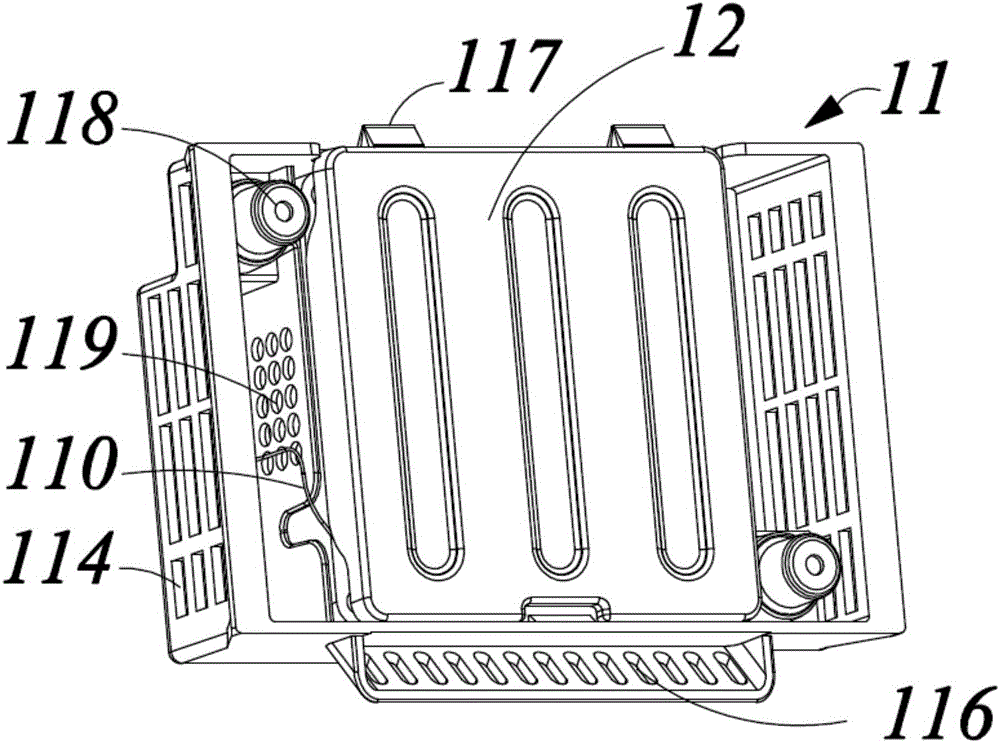

[0033] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings. Figure 1 to Figure 9 As shown, it is some preferred embodiments of the present invention.

[0034] figure 1 Shown is a three-dimensional schematic diagram of an embodiment of the integrated fan assembly of the present invention in an uncovered state, figure 2 It is a three-dimensional schematic diagram of the fan box (without fan) when it is not covered, image 3 The three-dimensional schematic diagram of the integrated fan assembly under the cover state, Figure 4 The top view of the one-piece fan assembly with the cover closed, Figure 5 Side view of the one-piece fan assembly with the cover closed.

[0035] As shown in the figure, the integrated fan assembly of the present invention includes an integrated fan box 1 and a fan 2, wherein the integrated fan box 1 includes a box body 11 and a box cover 12 arranged on the box body 11; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com