Two-section unpowered lifting ramp of cold storage side-hung door

A swing door, two-stage technology, used in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve problems such as difficulty in ensuring strength, reducing work efficiency, and inability to make fixed ramps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

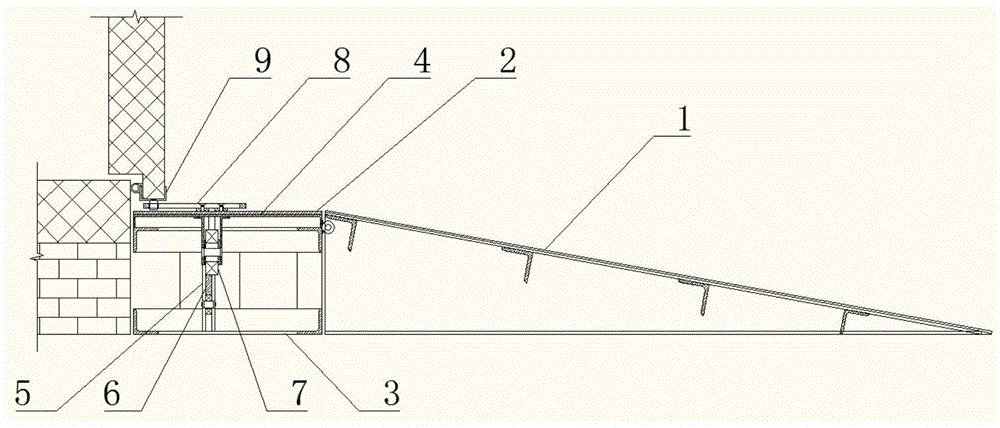

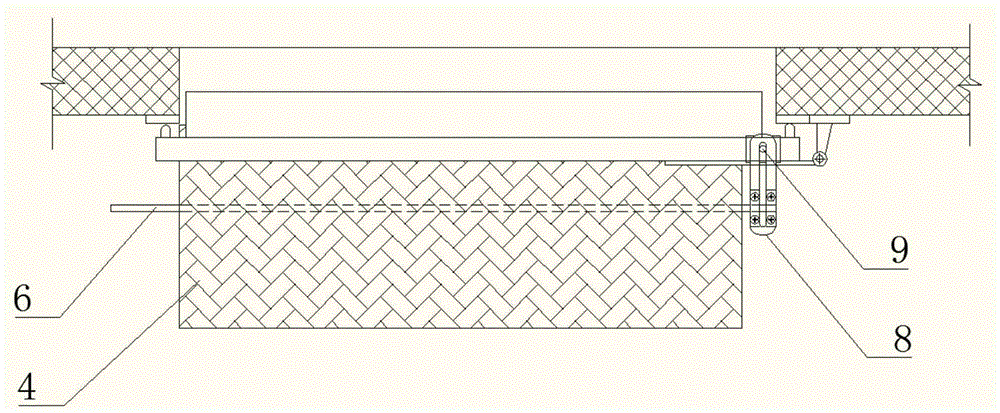

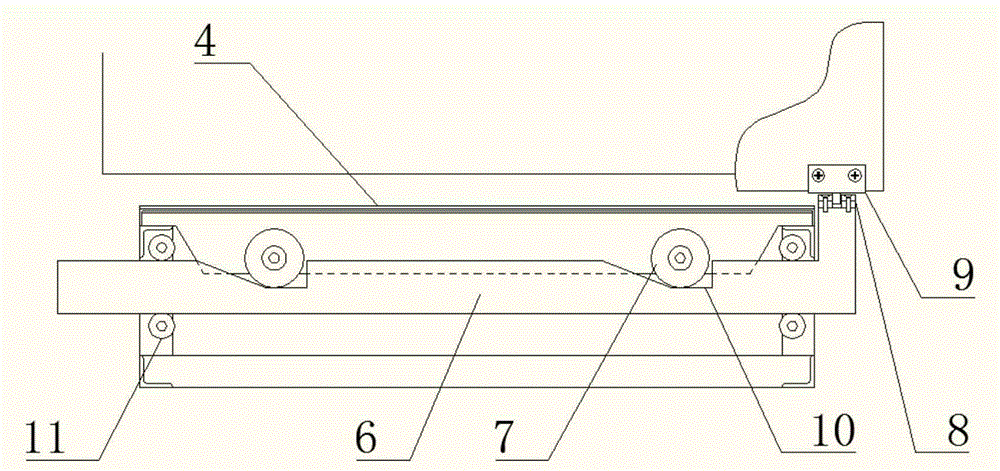

[0012] In the figure, 1. Fixed ramp; 2. Lifting ramp; 3. Underframe; 4. Lifting panel; 5. Slide rail groove; 6. Slide rail; 7. Roller; 8. Transmission groove plate; Components; 10, grooves; 11, slide rail fixing wheels.

[0013] Such as Figure 1-5 As shown, the lifting ramp 2 is placed close to the warehouse door, the fixed ramp 1 is located in front of the lifting ramp 2, and the lifting ramp 2 includes a chassis 3, a lifting panel 4 located above the chassis 3, a The slide rail groove 5 inside the frame 3, the slide rail 6 in the slide rail groove 5, the roller 7 located at the lower part of the lifting panel 4, the transmission groove plate 8 and the pin assembly 9 installed on one side of the slide rail 6, the bottom The frame 3 and the lifting panel 4 are connected by hinges, the slide rail 6 is provided with a groove 10, one side of the groove 10 is an inclined pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com