Optical fiber strain sensor and preparation method thereof

A fiber optic strain and sensor technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of temperature sensitivity, expensive system, and lower detection accuracy, and achieve the effect of simple preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

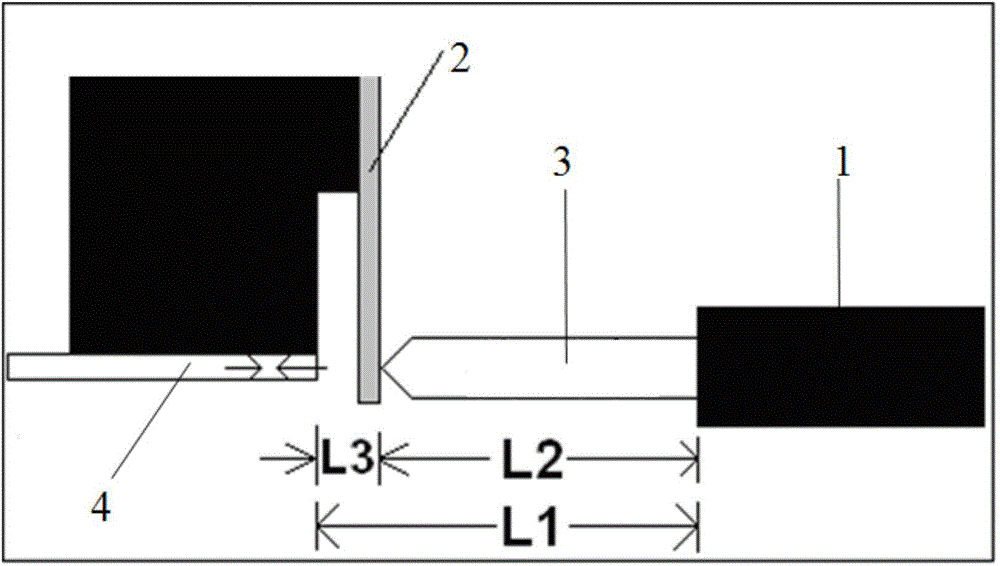

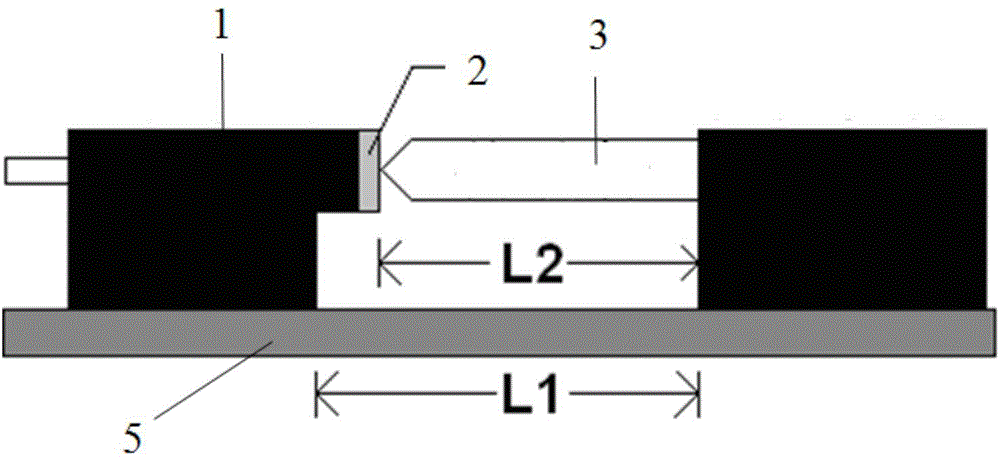

[0035] See attached figure 1 It is a schematic diagram (top view) of a kind of optical fiber strain sensor of the present embodiment; figure 2 It is a schematic diagram (side view) of an optical fiber strain sensor in this embodiment. An optical fiber strain sensor, comprising at least two fixed brackets 1, an optical fiber device 4, a transmission rod 3, and a cantilever beam 2, one end of the transmission rod 3 is fixed on one of the fixed brackets 1, and the other end of the transmission rod 3 is connected to the cantilever beam 2 For contact, the fiber optic device 4 and the cantilever beam 2 are fixed on another fixed bracket 1 , the fiber optic device 4 is used to emit the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com