Automobile part hole position checking fixture

A technology for auto parts and hole positions, applied in measuring devices, instruments, optical devices, etc., can solve problems such as complex structure, difficult detection, and easy deviation, so as to improve detection efficiency, smooth follow-up equipment, and ensure detection The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

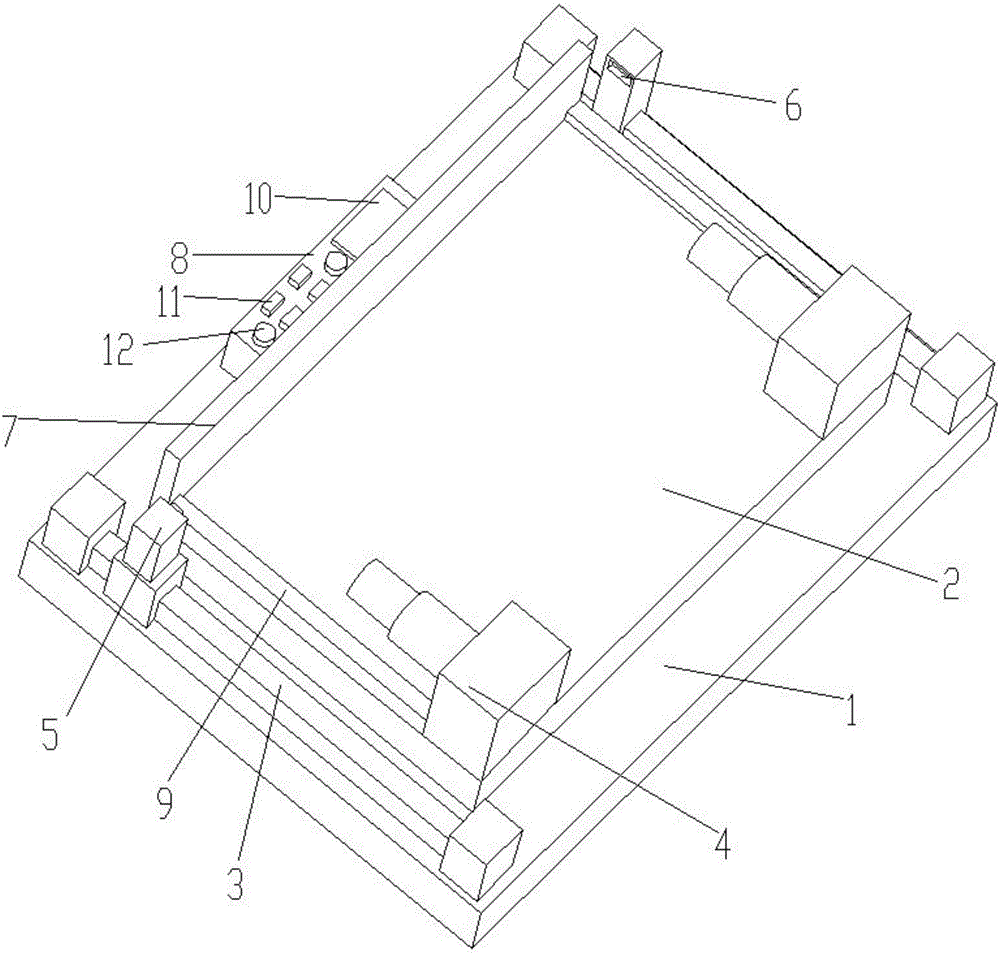

[0015] Embodiment: A kind of hole position inspection tool for auto parts, including a base 1, a detection table 2, an electric slide rail 3, an electric cylinder 4, an infrared transmitter 5 and an infrared receiver 6, and the detection table is fixed on the base of the base In the middle, there are two electric slide rails and they are symmetrically installed on both sides of the base, the detection platform is located between the two electric slide rails, and the infrared transmitter and infrared receiver are respectively slidably installed on the two sides of the base. On the two electric slide rails, the electric cylinders are two and installed symmetrically on both sides of the detection table, the electric cylinders are parallel to the electric slide rails, and the electric cylinders are opposite to the electric cylinders on the detection table One side is fixed with a positioning baffle 7, and also includes a controller 8, the controller is installed on the base, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com