Grinding apparatus

A pulverizing device and technology for pulverizing objects, which are applied in cyclone devices, grain processing, chemical instruments and methods, etc., can solve the problems of composition changes, inability to accommodate pulverized objects, and reduce pulverization efficiency, so as to prevent composition changes and prevent excessive The effect of load and smooth supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

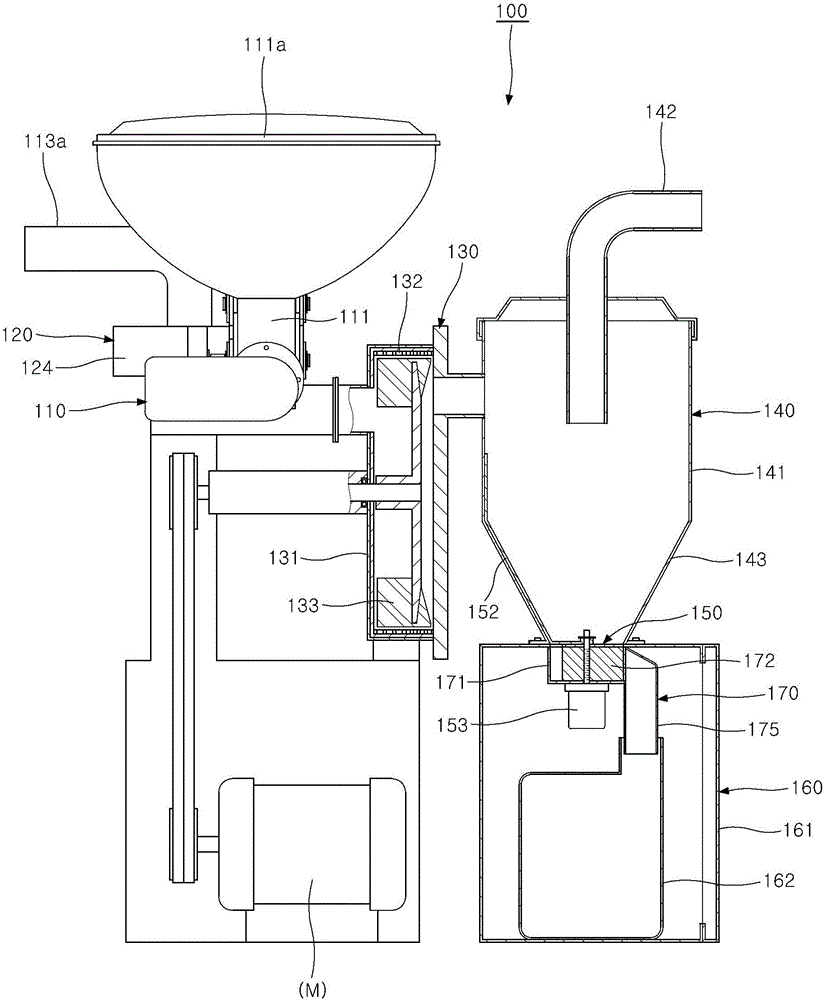

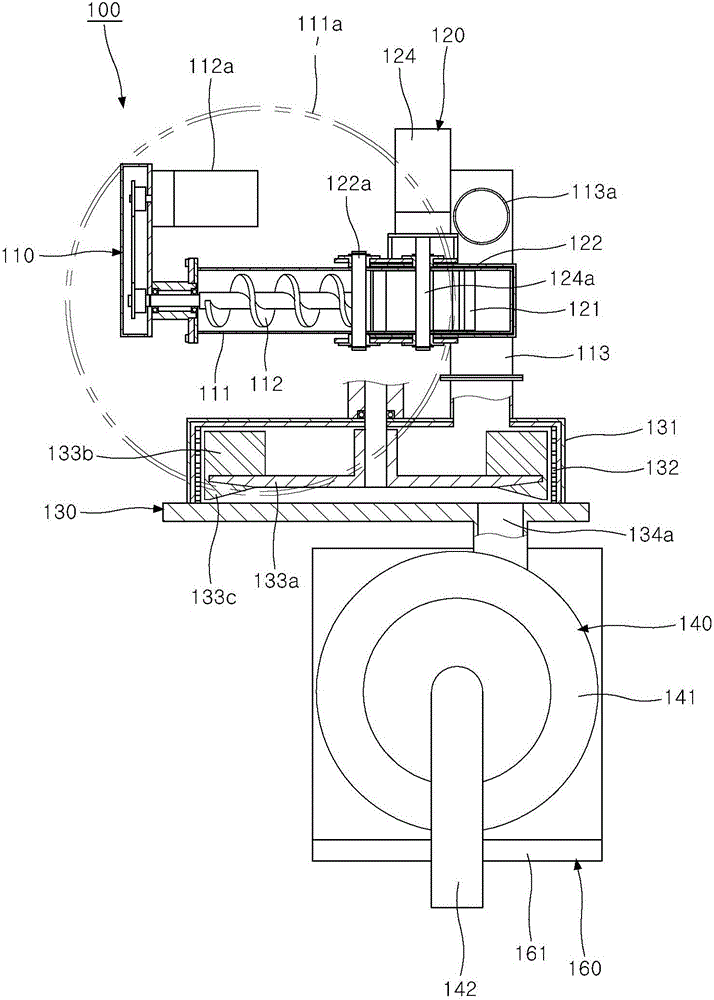

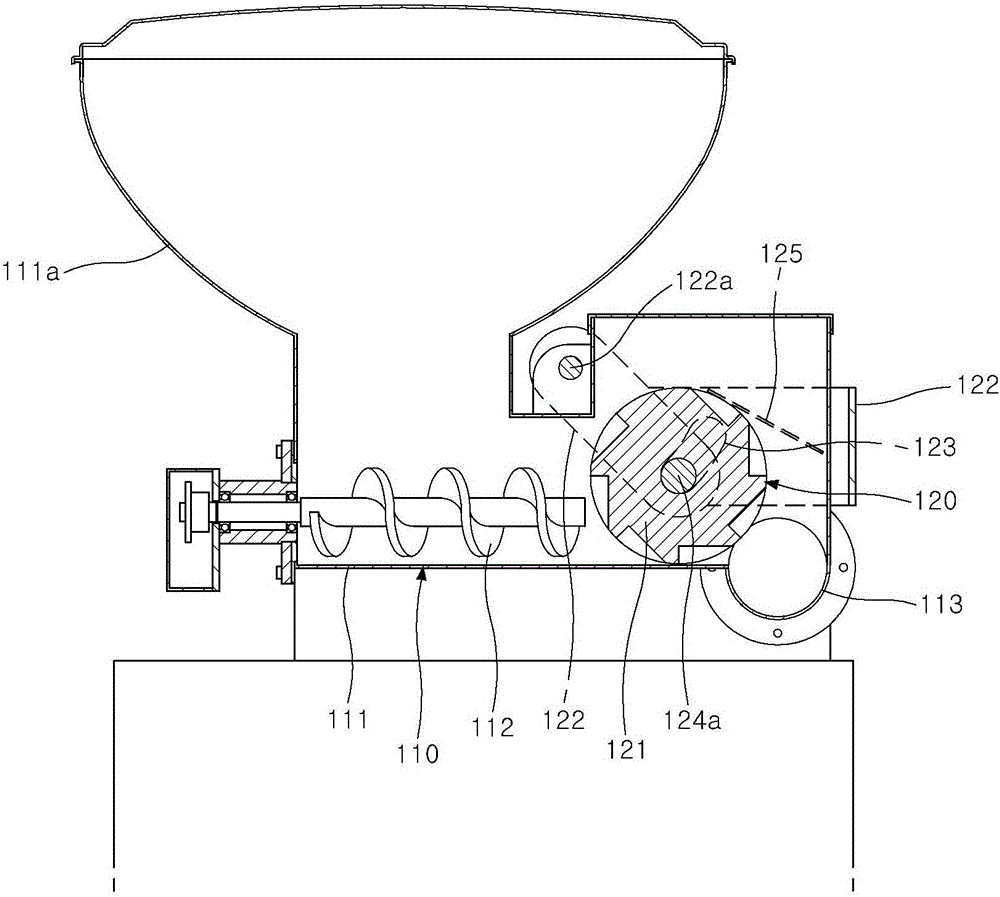

[0049] Hereinafter, the present invention will be described in detail based on the drawings. figure 1 Is the front structure diagram of the present invention, figure 2 It is a plan view of the present invention.

[0050] The crushing device 100 of the present invention includes: a transfer unit 110 that transfers the crushed objects thrown into the main body 111 through the hopper 111a to the side of the supply unit 120 by the rotation of the transfer screw 112; the supply unit 120 uses the supply rotor 121 The rotation of the feeder 110 supplies a predetermined amount of the crushed object transferred by the transfer unit 110 to the crusher 130, and when the amount of the crushed object transferred by the transfer unit 110 exceeds the predetermined amount, the supply rotor 121 is centered The shaft 124a rotates around the center and rises along the long guide hole 123 to supply the crushed object. The rising supply rotor 121 contacts the rising control piece 125 formed on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com