Inverse method die-lowering system and die-lowering method

An inverse method and mold reduction technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problem of the actual operation of the synchronism of the lifting bolt electric hoist traction, the higher requirements for the on-site arrangement of the lifting points, and the influence of maintenance deformation. and other problems to achieve the effect of improving material utilization, shortening construction period and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

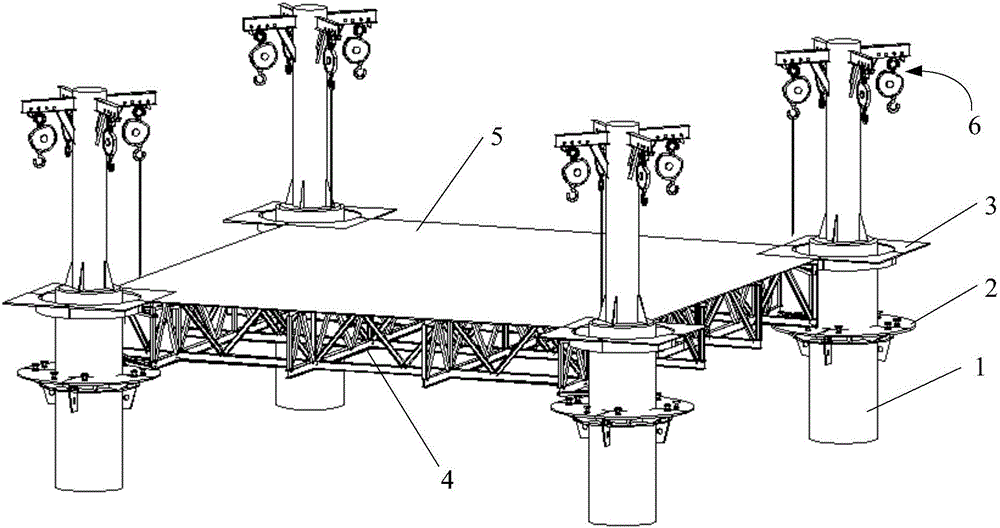

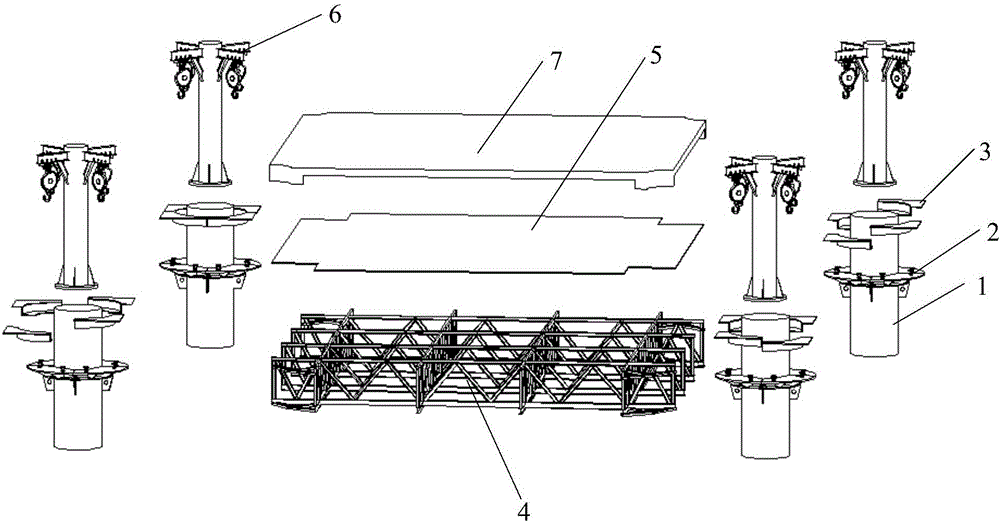

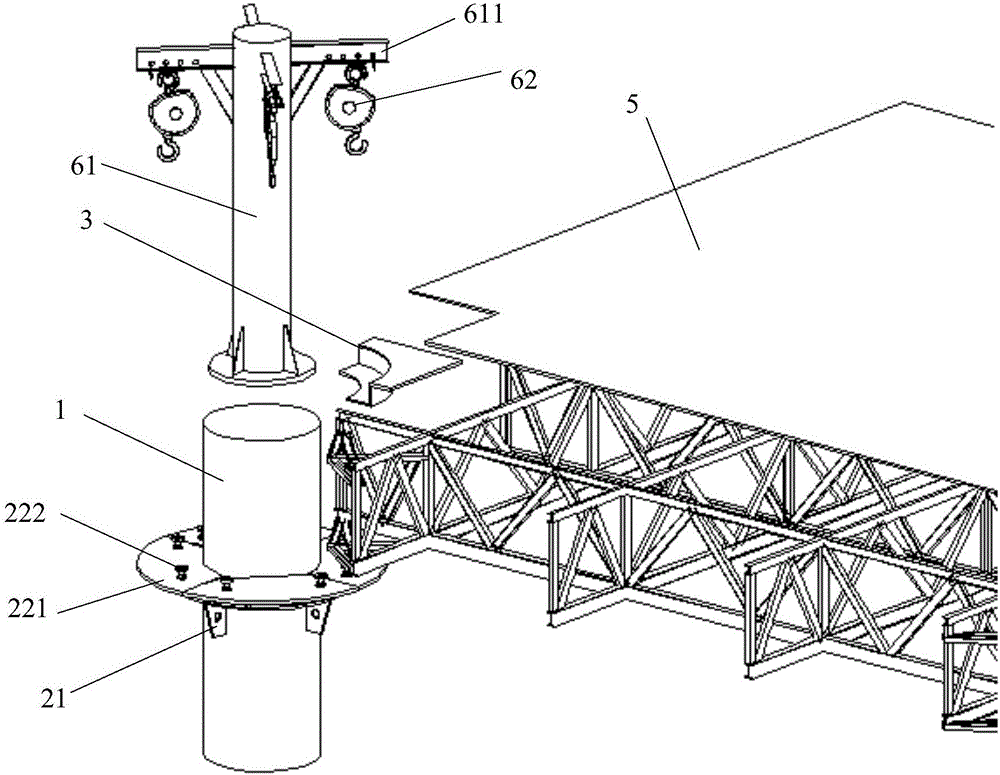

[0037] Such as Figure 1-7 As shown, the present invention provides a formwork lowering system of the reverse method, including a formwork support structure 2 and a hoisting mechanism 6 arranged on each structural column 1 in sequence from bottom to top, and trusses are set up on the formwork support structure 2 in sequence Structure 4, floor formwork 5 and column cap formwork 3, one side of the column cap formwork 3 is connected to the floor formwork 5, and the other side is connected to the structural column 1. Specifically, this embodiment uses one column distance as a unit for illustration, each structural column 1 corresponds to four adjacent units, and each unit corresponds to four structural columns 1, which are respectively arranged at the four corners of the rectangle. The formwork support structure 2 is based on The set floor height is installed, the hoisting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com