Compacted bentonite sample and preparation method

A technology of bentonite and pressure equipment, which is applied in the field of compacted bentonite samples and preparation, can solve the problems of uniform water mixing, limited range of compactness, difficulty, etc., and achieves increasing non-uniformity coefficient, delaying expansion time, and environmental protection of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

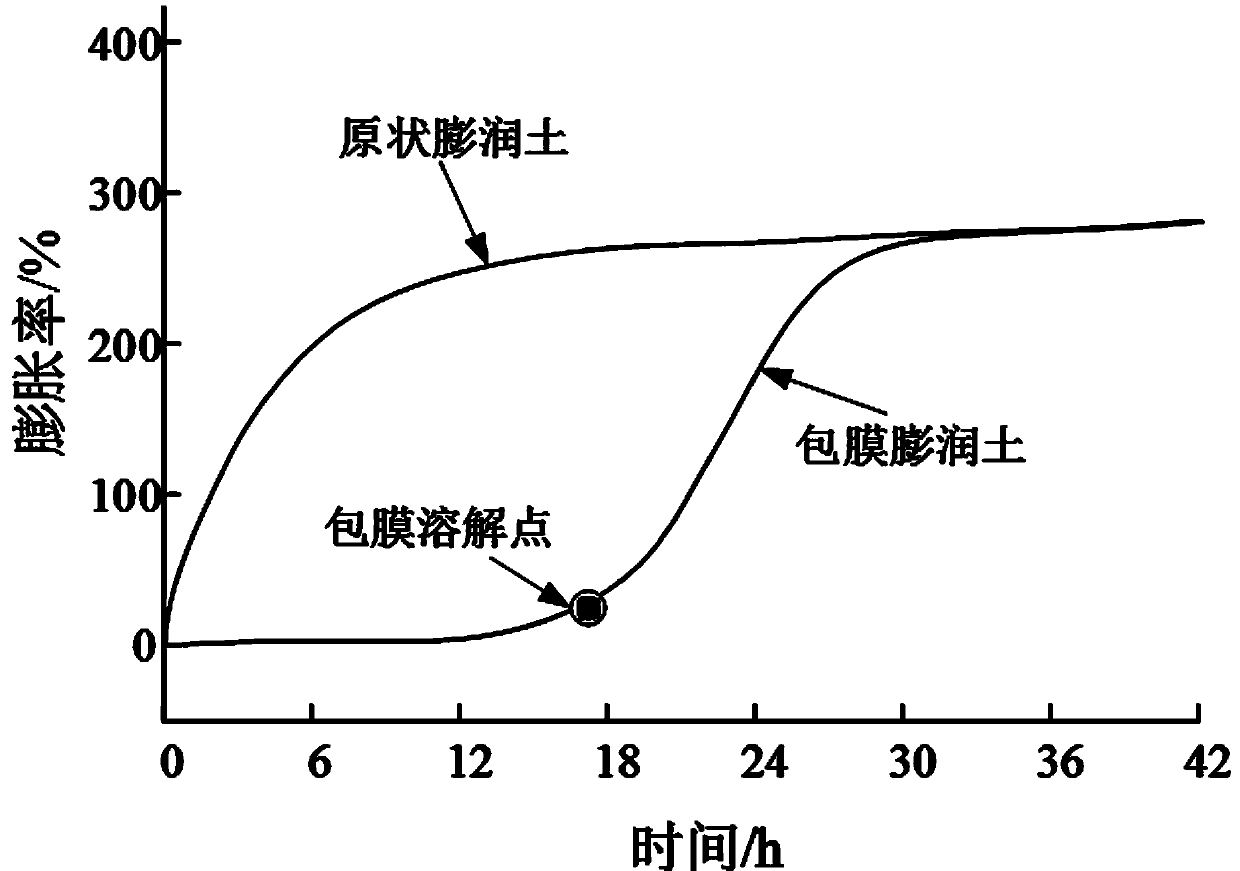

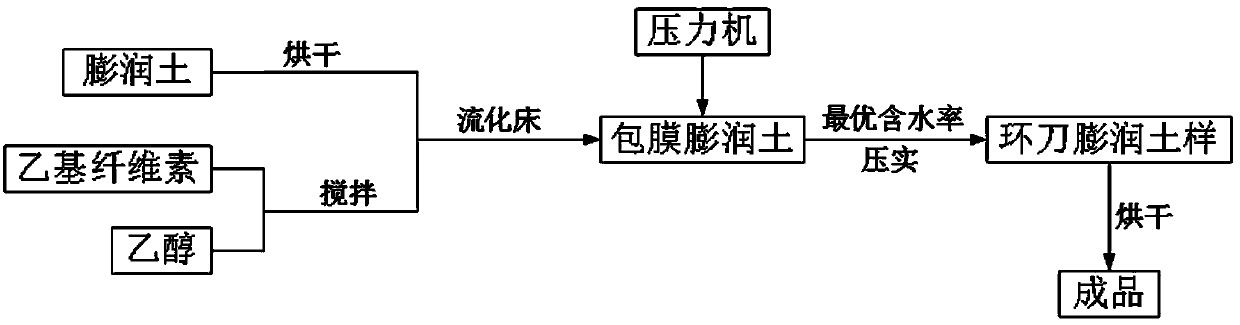

[0039] A compacted bentonite sample. The bentonite is coated with a coating dispersion liquid, and then the coated bentonite is compacted with a pressure device according to a predetermined dry density according to the optimal water content, and the compacted bentonite is dried. A compacted bentonite sample was obtained. Such as figure 2 Among them, the use of coated bentonite can delay the interaction time between water and bentonite, and control the swelling of bentonite samples before the test officially starts.

[0040] In a preferred solution, the component of the coating dispersion liquid is ethyl cellulose dissolved in ethanol, wherein the content of ethanol is 20%-40% by weight. Preferably, the volume concentration of ethanol in this example is more than 75%, and further preferred ethanol is absolute ethanol. In a preferred solution, the coating thickness is controlled by adjusting the ethanol content. When the ethanol content is higher, the envelope thickness is t...

Embodiment 2

[0057] 1. Take an appropriate amount of bentonite and spread it in a tray with a thickness of 1cm, and place it in an oven at 105°C for 12 hours. After drying, take 160g of bentonite and place it in the material tank of the fluidized bed.

[0058]2. Add 32g of ethyl cellulose into the reaction vessel, and slowly add 8g of ethanol solution. Stir well with a glass rod to obtain an ethyl cellulose dispersion, and pour the ethyl cellulose dispersion into a binder preparation tank in a fluidized bed spray system.

[0059] 3. Preheating the fluidized bed with an empty machine. There are two main purposes of the empty machine preheating: the initial air intake of the fluidized bed is generally unstable, and the equipment can be guaranteed after a certain period of time through the empty machine preheating. This parameter tends to be stable, so as to avoid the adverse effect of parameter instability on subsequent material preheating; secondly, through machine preheating, the material ...

Embodiment 3

[0068] 1. Take an appropriate amount of bentonite and spread it in a tray with a thickness of 1cm, and place it in an oven at 105°C for 12 hours. After drying, take 160g of bentonite and place it in the material tank of the fluidized bed.

[0069] 2. Add 24g of ethyl cellulose into the reaction vessel, and slowly add 16g of ethanol solution. and fully stirred with a glass rod to obtain an ethyl cellulose dispersion, and pour the ethyl cellulose dispersion into a binder preparation tank in a fluidized bed spray system.

[0070] 3. Preheat the fluidized bed with empty machine. There are two main purposes of empty machine preheating: First, the initial air intake of the fluidized bed is generally unstable. It can ensure that the parameter tends to be stable, and avoid the adverse effect of parameter instability on subsequent material preheating; second, through machine preheating, it can greatly reduce the material preheating time and improve efficiency.

[0071] 4. Preheating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com