Battery liquid injection production line feeding device

A production line and liquid injection technology, which is applied in the field of charging devices for battery liquid injection production lines, can solve problems such as manual inspection, inability to guarantee transmission speed and synchronization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

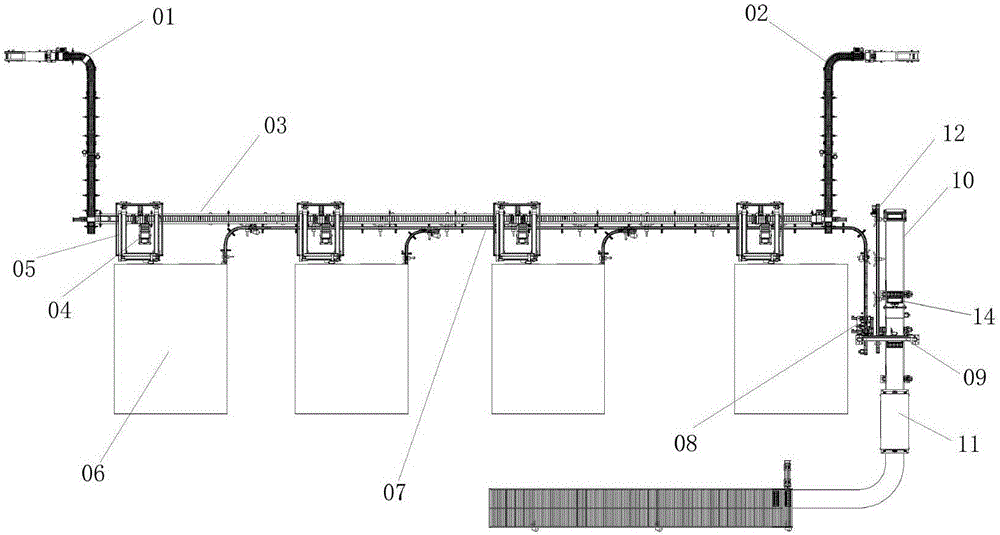

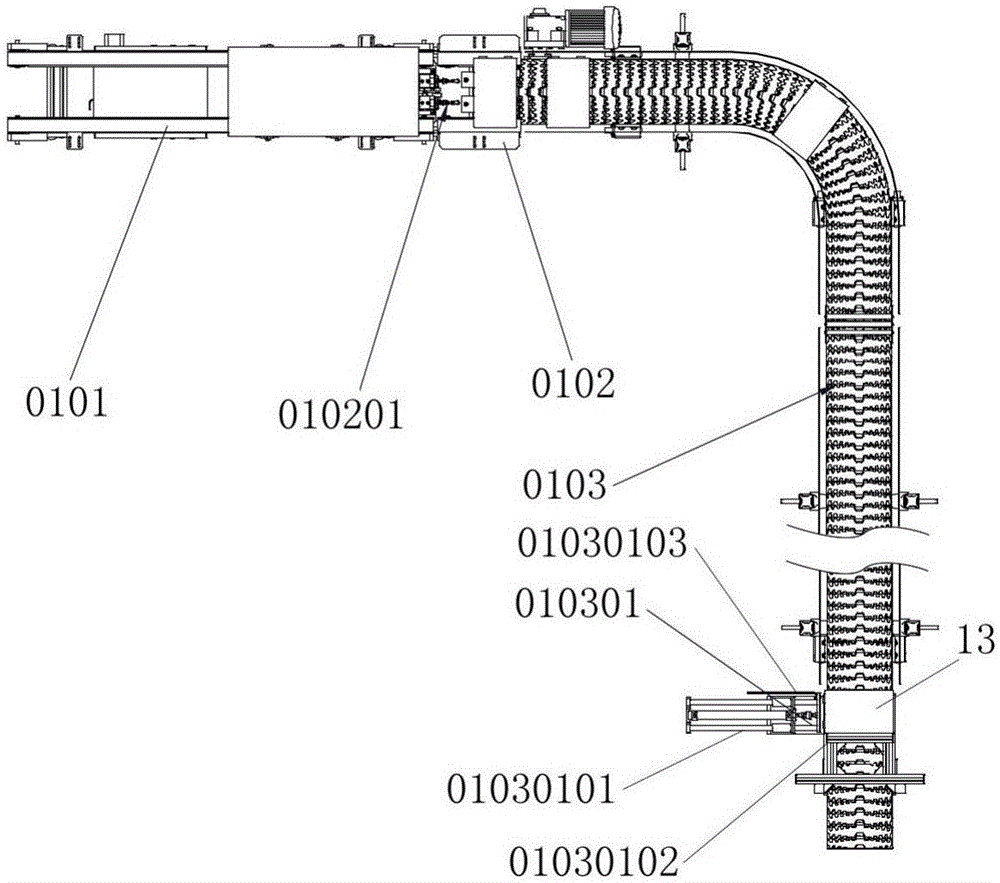

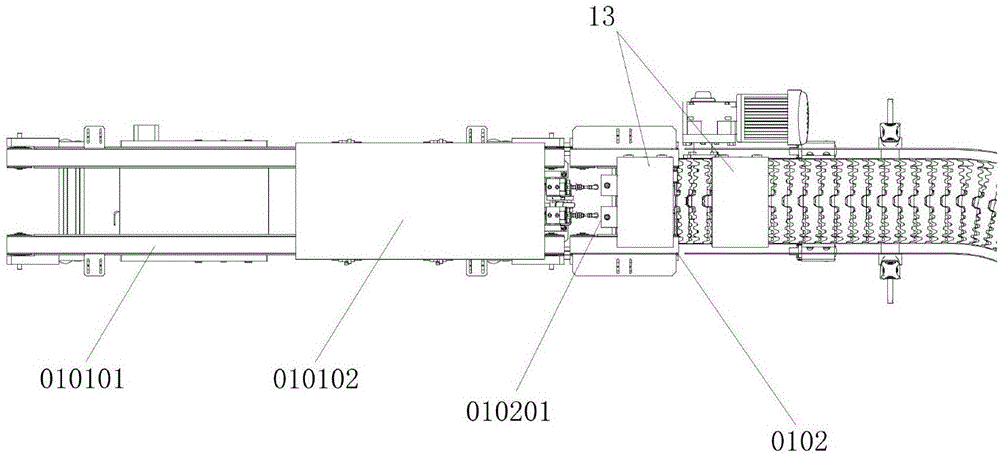

[0034] Such as figure 1 As shown, this embodiment consists of the first retrieving line 01, the second retrieving line 02, the conveying line 03, the diversion line 04, the liquid injection robot 05, the liquid injection machine 06, the positioning line transmission section 07, and the positioning line positioning end 08. Palletizing robot 09, stacking line 10, sealed cabin 11, and waste line 12. The first retrieving line 01 and the second retrieving line 02 are symmetrically arranged at both ends of one side of the conveying line 03. The conveying line 03 can be Two-way movement. The workflow of this embodiment is to take off the battery 13 from the vacuum baking line (not shown in the figure) (see figure 2 ), and the battery 13 is laid flat through the first retrieving line 01 and the second retrieving line 02, and then transferred to the conveying line 03, and the battery 13 is shunted on the conveying line 03 into the shunt line 04, and the shunt line 04 will After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com