Paint brush roller

A paint brush and roller technology, applied in the field of paint brush rollers, can solve the problem of uneven paint thickness, and achieve the effects of not easy to let go, easy to use, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

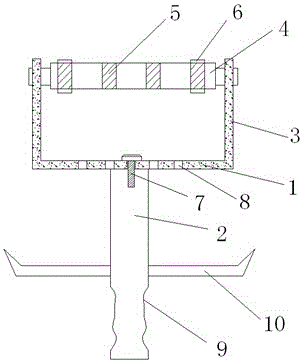

[0019] like figure 1 As shown, a paint brush roller of the present invention includes a bracket 1, a handle 2 is connected to the bottom of the bracket 1, and support arms 3 are arranged symmetrically on both sides of the bracket 1, and a roller shaft 4 is arranged inside the support arm 3, and the roller shaft 4 is interspersed and fixed Inside the support arm 3 , a number of threaded rings 5 are evenly distributed on the roller shaft 4 , and the roller shaft 4 is provided with two limiting blocks 6 threadedly connected with the threaded rings 5 .

[0020] The bracket 1 and the handle 2 are connected by bolts 7 , and the bolts 7 pass through the fixing holes 8 on the bracket 1 and are fixed inside the handle 2 .

[0021] Several fixing holes 8 are evenly distributed on the bracket 1 .

[0022] A handle 9 is provided at the end of the handle 2 .

[0023] A paint shielding portion 10 is provided on the handle 2 at the upper end of the grip portion 9 .

[0024] In the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com