Tool for brushing in cavity

A brushing and tooling technology, applied in the field of brushing tools in the cavity, to achieve the effect of reducing the bearing weight and increasing the brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

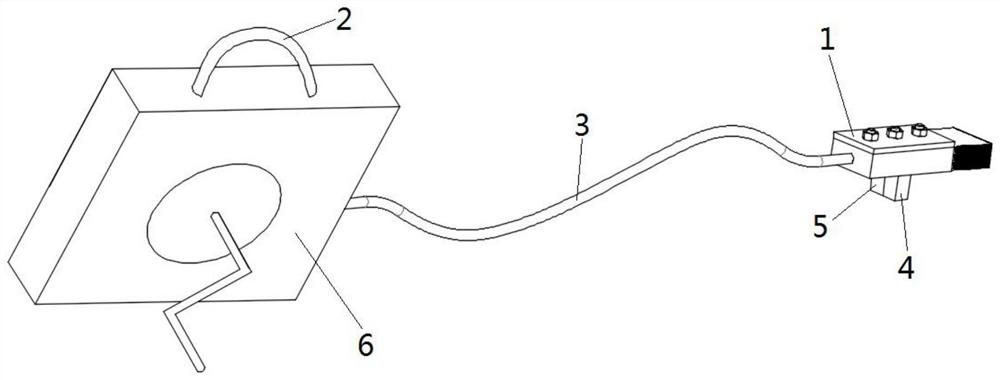

[0028] see Figure 1 to Figure 2 , a tool for brushing in the cavity, this embodiment is applied to the paint brushing on the inner wall of the cavity of the fuel tank.

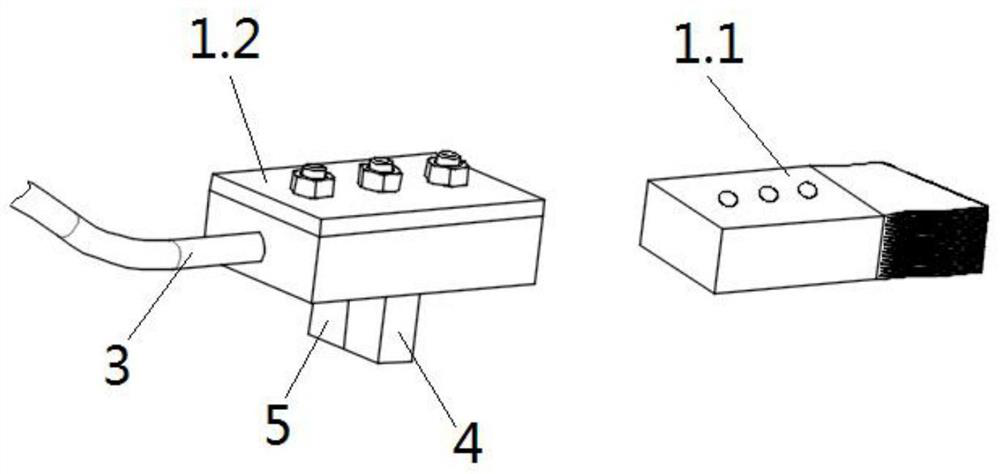

[0029] A tool for brushing in a cavity, including a brush head assembly 1, a handle 2, and an angle adjustment member 3 connected between the brush head assembly 1 and the handle 2, which is convenient for adjusting the position of the brush head assembly 1, and for the oil tank The limited area (dead angle area) of the inner wall of the cavity is repaired; figure 1 As shown, the brush head assembly 1 is provided with a miniature camera 4, which is used to observe the uniformity of the coating inside the fuel tank cavity. Dip the paint on the top, extend the brush head assembly 1 into the inside of the fuel tank cavity, observe the unsprayed area inside the fuel tank body through the micro camera 4, and repaint the area. In this embodiment, the brush head assembly 1 The dimensions of length, width and heigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com