A kind of quick-drying non-benzene alkyd coating and preparation method thereof

A benzene-free alkyd-free coating technology, applied in the field of coatings, can solve the problems of slow surface drying, strong odor of aromatic solvents, and inability to form effective protection for complex types of circuit boards, so as to improve adhesion and ensure coating The effect of covering quality and improving protection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

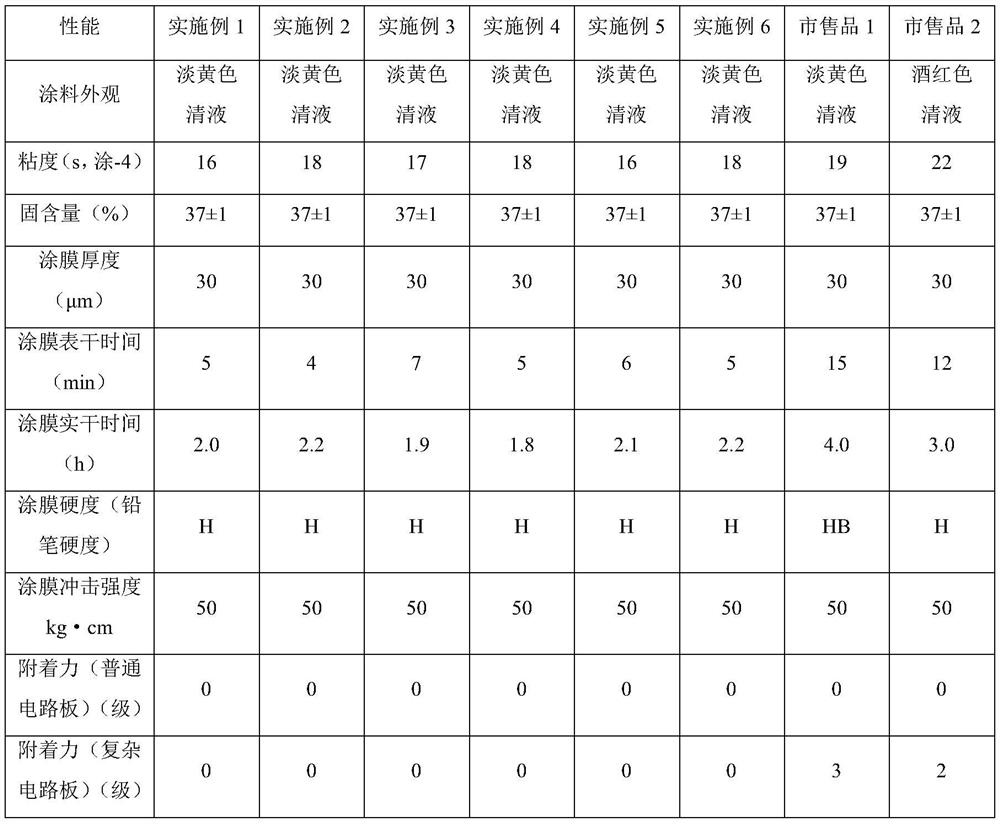

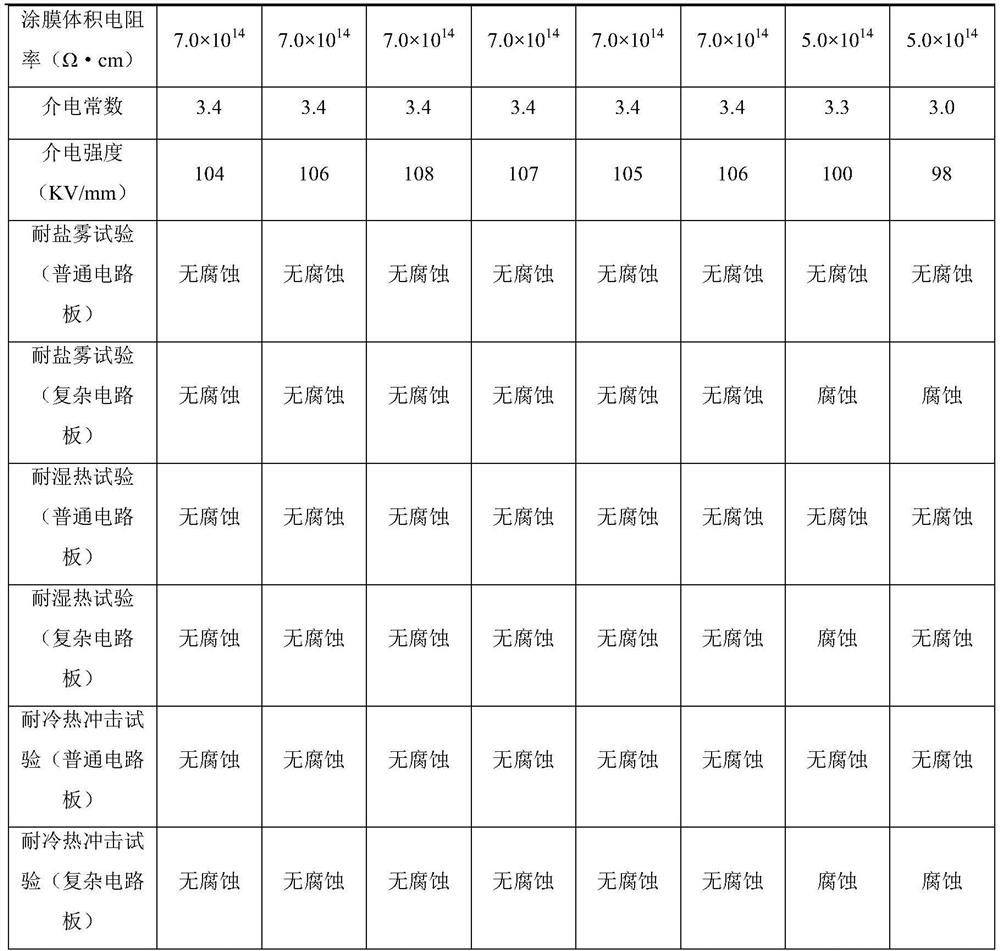

Examples

preparation example Construction

[0028] Preparing fast-drying alkyd benzene-deposited coatings of the present invention comprises the steps of:

[0029] Step S1: Preparation of modified alkyd resins: add 20 to 60 parts of unsaturated fatty acids and 10 to 20 parts of a polyol, 0.01 to 1 part of a catalyst and 20 to 50 parts of a solvent, 200 to 50 parts of a solvent in 200. The esterification reaction is altered at ° C, and the alkyd resin prepolymetric with a hydroxyl group is generated, and the temperature is reduced to 70 ° C, and then 1 to 10 parts of the isocyanate resin is added thereto, and the alkyd resin prepolymers containing an end isocyanate are reacted. 4 to 16 parts of epoxy resin were added, reacted at 70 ° C, generated an end-epoxycanolic acid prepolymer, and 2 to 12 parts of multi-amine were added to the kettle, and the reaction was reacted at room temperature. Alkyd resin;

[0030] Step S2: At room temperature, 20 to 90 parts of the modified alcoholic acid resin obtained in step S1, 1 to 20 part...

Embodiment 1

[0037] Fast-drying alkyd benzene-deposited coatings of the present embodiment comprises the following component parts by weight: 20 parts modified alkyd resin, 18 parts of environment-friendly organic solvent, 0.5 parts of hydrogenated petroleum resin and 0.5 parts of nitrocellulose, reminders drying agent ethylhexanoate vanadium (vanadium +4 valence) ethylhexanoate and 0.4 parts of manganese (+2 valence) 0.6 parts, 0.05 parts of a leveling agent BYK-307,0.05 parts of a defoamer BYK-054,0.05 parts of the anti settling agent BYK-102, anti-skinning agents butyraldehyde oxime 0.05 parts, ordinary fillers photo storage phosphor nano silica and 0.2 parts 2.8 parts; environment-friendly organic solvent is an isoparaffin Exxon Isopar series IsoparE, Isopar G, Isopar H, Isopar L, Isopar M, Isopar N, Exxsol series of de-aromatised Exxsol D30, Exxsol D40 one or more of.

[0038] Oil-modified alkyd resin of 45 to 55%; modified alkyd resin comprises the following parts by weight of component:...

Embodiment 2

[0048] Fast-drying alkyd benzene-deposited coatings of the present embodiment comprises the following component parts by weight: 35 parts modified alkyd resin, 10 parts of environment-friendly organic solvent, 6 parts of hydrogenated terpene resin, zinc octoate drier iso (Zn +2 valence) 2 parts, 0.5 parts of a leveling agent, BYK-302,0.5 parts of a leveling agent, defoamer BYK-378,0.8 parts BYK-060N, 1.2 parts of a defoamer BYK-066N, 1 parts anti-settling agent BYK-108,1 parts of anti-settling agent BYK-116, anti-skinning agent, 3 parts of cyclohexanone oxime, security short-wave ultraviolet fluorescent pigment 0.3 parts and 0.7 parts by nano alumina; environment-friendly organic solvent is Isopar Exxon Mobil series isoparaffin Isopar E, Isopar G, Isopar H, Isopar L, Isopar M, Isopar N, Exxsol series of de-aromatised Exxsol D30, Exxsol D40 one or more of.

[0049]The modified alkyd resin oil degree is 45 to 55%; the modified alkyd resin contains 35 parts by weight: 10 of linoleic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com