Rotary barrel of granulator

A granulator and drum technology, applied in the direction of mold extrusion granulation, etc., can solve the problems that are not conducive to the continuous use of the granulator, blockage of the granulation chamber, etc., to ensure safety, availability, effectiveness, and easy installation and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

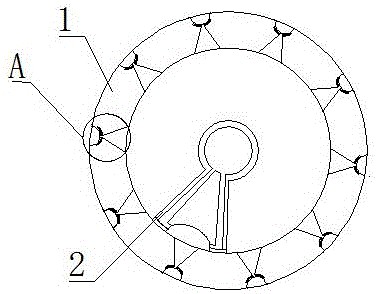

[0030] Such as Figure 1-3 As shown, the invention discloses a drum of a granulator, which includes a cylinder body 1 and an air injection mechanism 2. The cylinder body 1 has a cavity inside, and the air injection mechanism 2 is located in the cavity and is in sealing contact with the side wall of the cavity. The mechanism 2 does not rotate with the cylinder body 1, and the outer surface of the cylinder body 1 is provided with a granulation chamber 11, which communicates with the air injection mechanism 2. The structure sprays air through the air injection structure, so as to prevent the drum of the granulation equipment from being clogged by rolling, improve the granulation efficiency, and prevent the clogging of the drum surface.

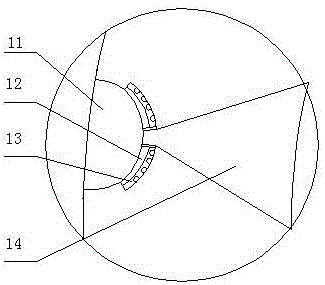

[0031] There is a tapered booster chamber 14 on the side wall of the cylinder body 1 , the output port of the booster chamber 14 communicates with the granulation chamber 11 , and the input port of the booster chamber 14 communicates with the air...

Embodiment 2

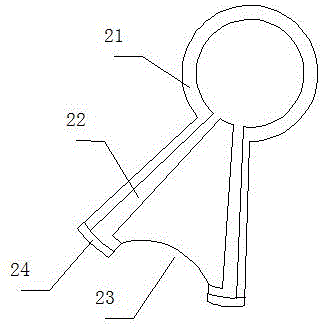

[0038] The invention discloses a drum of a granulator, which comprises a cylinder body 1 and an air injection mechanism 2. The cylinder body 1 has a cavity inside, and the air injection mechanism 2 is located in the cavity and is in sealing contact with the side wall of the cavity. The cylinder body 1 rotates, and a granulation chamber 11 is arranged on the outer surface of the cylinder body 1 , and the granulation chamber 11 communicates with the air injection mechanism 2 . The air injection mechanism 2 includes an air injection pipe 21, an air delivery channel 22, an air injection pipe 21 and a sealing portion 24; a conical booster chamber 14 and an elastic portion 12 are arranged on the rear side of the granulation chamber 11, and the elastic portion 12 is provided on the rear side The buffer chamber 13 is provided with an annular protrusion on the side wall of the buffer chamber 13; the output port of the pressurization chamber 14 is connected to and aligned with the granul...

Embodiment 3

[0041] Based on the structure of embodiment 1 or implementation 2, the anti-clogging method of its granulation cavity 11 is:

[0042] Step 1: After the barrel 1 rotates to the specified position, the gas gathering chamber 23 is aligned with a pressurized chamber 14, and the sealing part 24 is sealed with the inner side walls of the barrel 1 on both sides of the pressurized chamber 14;

[0043] Step 2: Inject air into the air injection pipe 21 at a speed of 0.1-0.15m³ / min, the air enters the gas gathering chamber 23 after passing through the air delivery channel 22, and generates an air pressure of 60-80pa at the detour to make the sealing part 24 close The inner wall of cylinder 1;

[0044] Step 3: After the air flow gathers through the pressurized part, it enters the granulation chamber 11 at a speed of 15-20m / s; when the granulation chamber 11 is blocked, the airflow compresses the elastic part 12, increasing the air pressure of the granulation chamber 11 until granulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com