Double Roller Shredder

A technology of shredders and knife rollers, which is applied in the direction of grain processing, etc., can solve the problems of insufficient utilization of knife materials, troublesome removal and replacement of moving knives, loose screws or wear, etc., to achieve convenient disassembly and replacement of knife tips, Ingenious structural design, reducing the effect of instantaneous load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

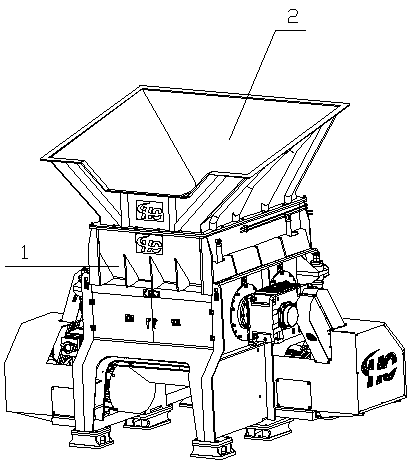

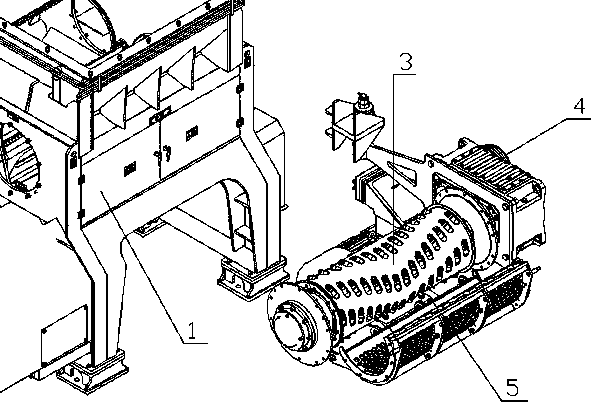

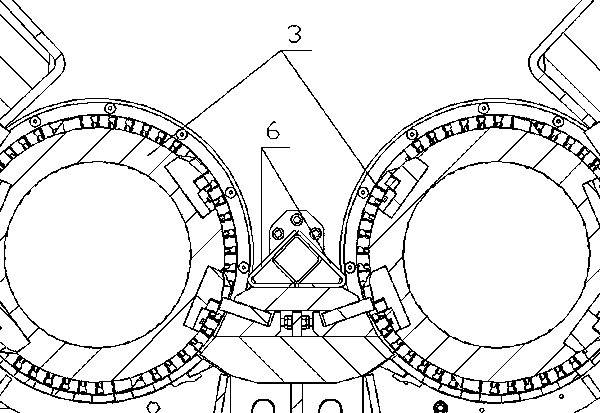

[0041] Example: twin roll shredder, such as Figure 1~10 As shown, it includes a chassis 1, a feed hopper 2, a knife roller 3, a power mechanism 4 and a control system. The chassis 1 is used as a carrier for other components of the double-roller shredder, and has a crushing chamber inside, and the crushing chamber is provided with a fixed knife group 11 . The feeding hopper 2 is arranged on the machine case 1, communicates with the crushing chamber, and serves as the feeding inlet of the double-roll shredder. The knife roller 3 is set in the crushing cavity of the machine case 1, and the surface is provided with a moving knife set 31 which cooperates with the fixed knife set 11 for shearing. The moving knife set 31 is arranged in a V shape, so that there are no more than two sets of moving Cutting between the knife and the fixed knife reduces the instantaneous load and prolongs the service life of the moving knife. The power mechanism 4 drives the knife roller 3 to rotate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com