Inclined conveyor bearing outer ring cleaning device

A technology for bearing outer rings and cleaning devices, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of small direct contact area, large contact area between the outer ring and the conveyor belt, and poor cleaning effect To avoid problems such as poor quality, to achieve the effect of large direct contact area and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

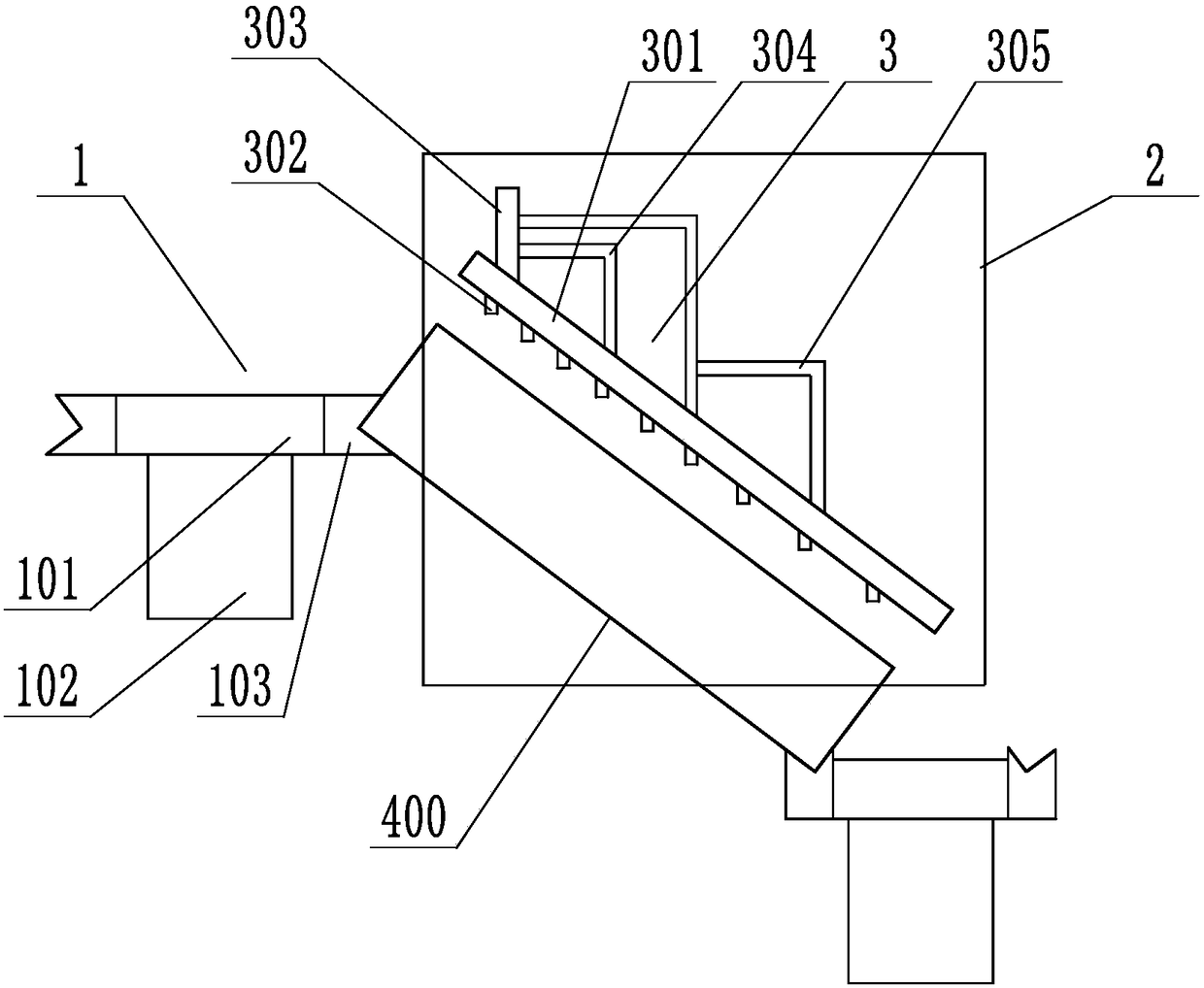

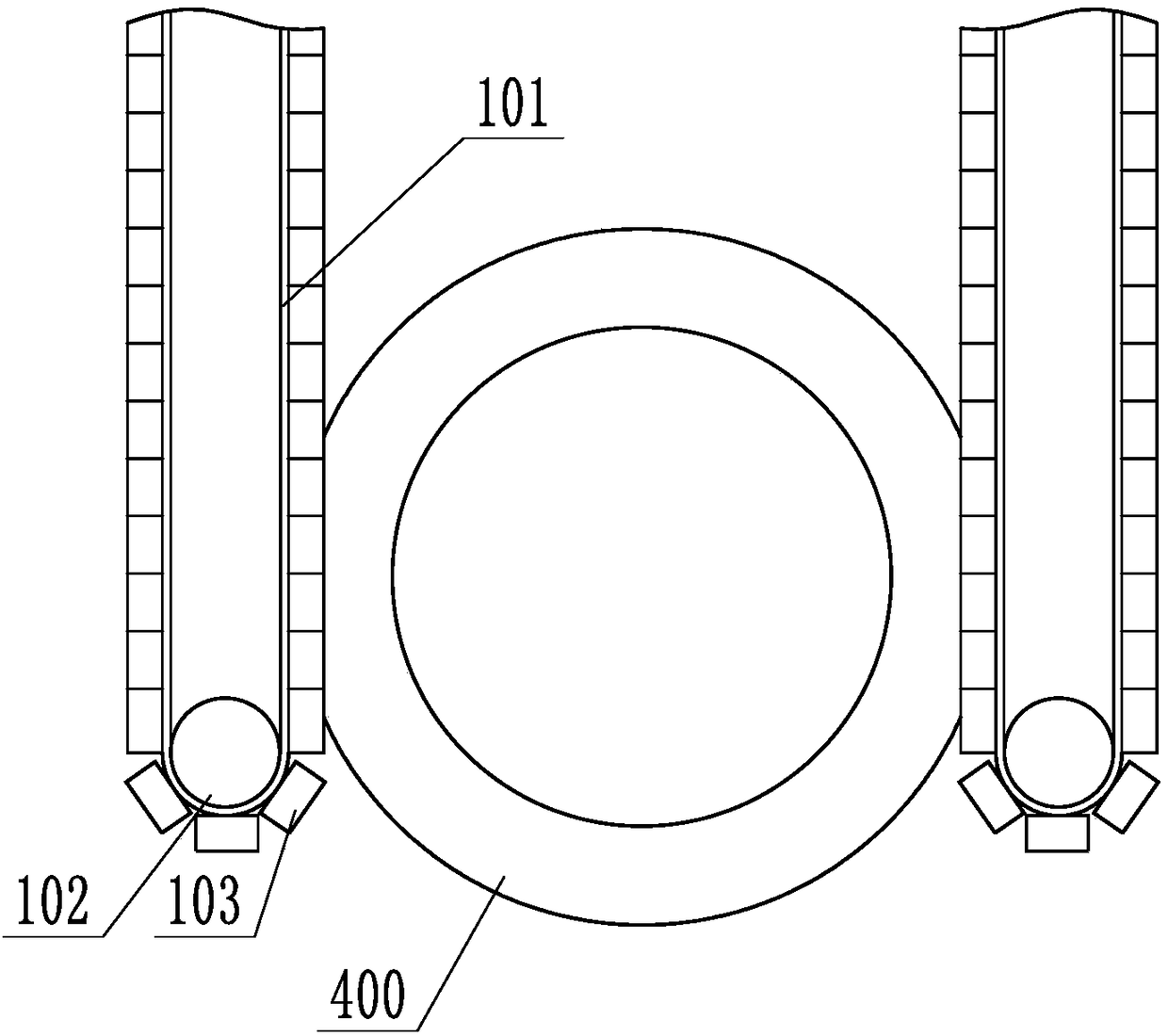

[0014] Such as figure 1 , figure 2 As shown, the inclined conveying type bearing outer ring cleaning device of this embodiment includes a conveying assembly 1 for conveying the bearing outer ring, a cleaning box 2 and a cleaning head 3 placed in the cleaning box 2, and the conveying assembly 1 includes , two conveyor belts 101 staggered up and down and a geared motor 102 for driving the conveyor belt 101, the bearing outer ring 400 is supported obliquely between the two conveyor belts 101, and the support for the outer edge angle of the bearing outer ring 400 is installed on the conveyor belt 101 Block 103 : the cleaning head 3 includes a cleaning tray 301 arranged obliquely, a liquid inlet pipe for cleaning liquid is installed on the cleaning tray 301 , and a liquid spray nozzle 302 is provided on the lower surface of the cleaning tray 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com