All-electric servo numerical-control bending machine with upper die load monitoring and protecting device and method thereof

A load monitoring and protection device technology, applied in safety equipment, manufacturing tools, metal processing, etc., to achieve the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

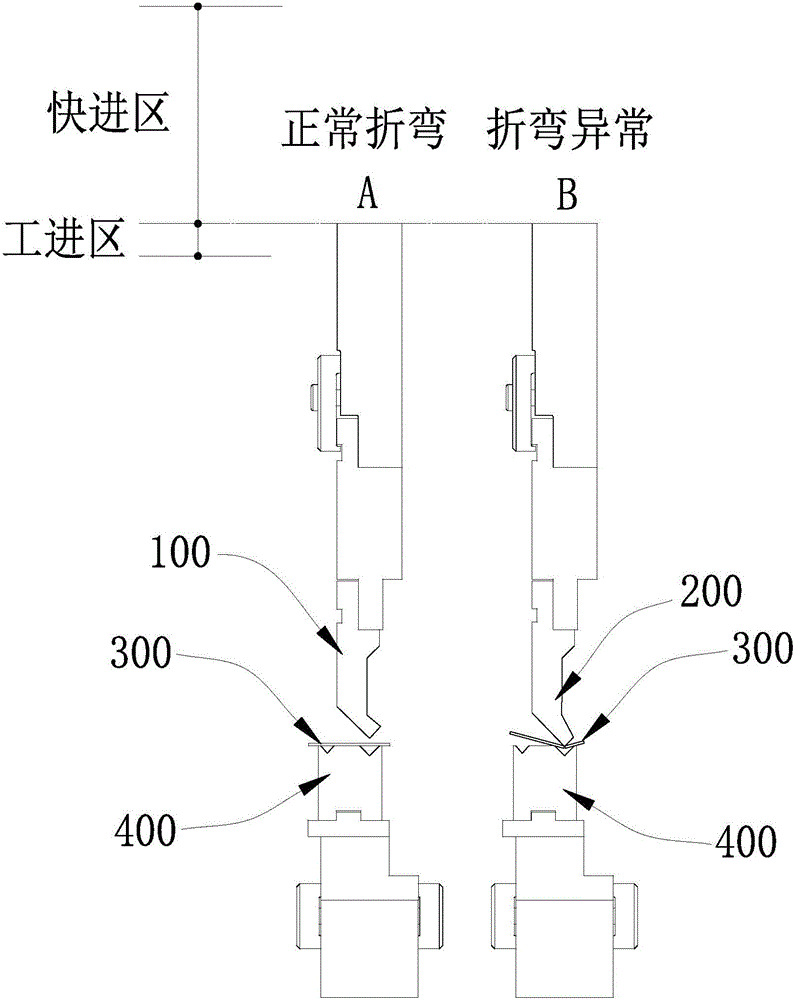

[0056] Such as image 3 As shown, A is the normal bending condition, B is abnormal bending; among them, the upper mold 100 is the normal upper mold, and the upper mold 200 is the wrong upper mold installed by mistake, and the height of the upper mold 200 is 10mm longer than the upper mold 100 ; Set the working distance as 15mm; then set the load value of the upper die required in the fast-forward area to 3 tons, and then set the load value of the upper die required to bend workpieces 300 in the working area to 10 tons; determine the abnormal load of the upper die It means that in the fast-forward area, the current feedback actual die load value exceeds the preset upper die load value by more than 5 tons.

[0057] A: Under normal bending conditions, after the upper mold 100 enters the working area from the fast-forward area, the speed gradually decreases and enters the workpiece bending process. B is an abnormal bending situation. Since the upper die 200 is 10mm longer than th...

Embodiment 2

[0059] Such as image 3 As shown, A is the normal bending condition, B is abnormal bending; among them, the upper mold 100 is the normal upper mold, and the upper mold 200 is the wrong upper mold installed by mistake, and the height of the upper mold 200 is 10mm longer than the upper mold 100 ; Set the working distance as 15mm; set the load of the upper die required in the fast-forward area to be 3 tons, and then set the load of the upper die required to bend the workpiece in the working area to be 5 tons; the condition for determining the abnormal load of the upper die is The current feedback in the entering area is that the actual die load value exceeds the preset upper die load value by more than 5 tons.

[0060] B is an abnormal bending situation. Since the upper mold 200 is 10mm longer than the height of the upper mold 100, the upper mold 200 bends the workpiece 300 in advance in the fast-forward zone. At this time, the servo drive detects that the actual mold load value ...

Embodiment 3

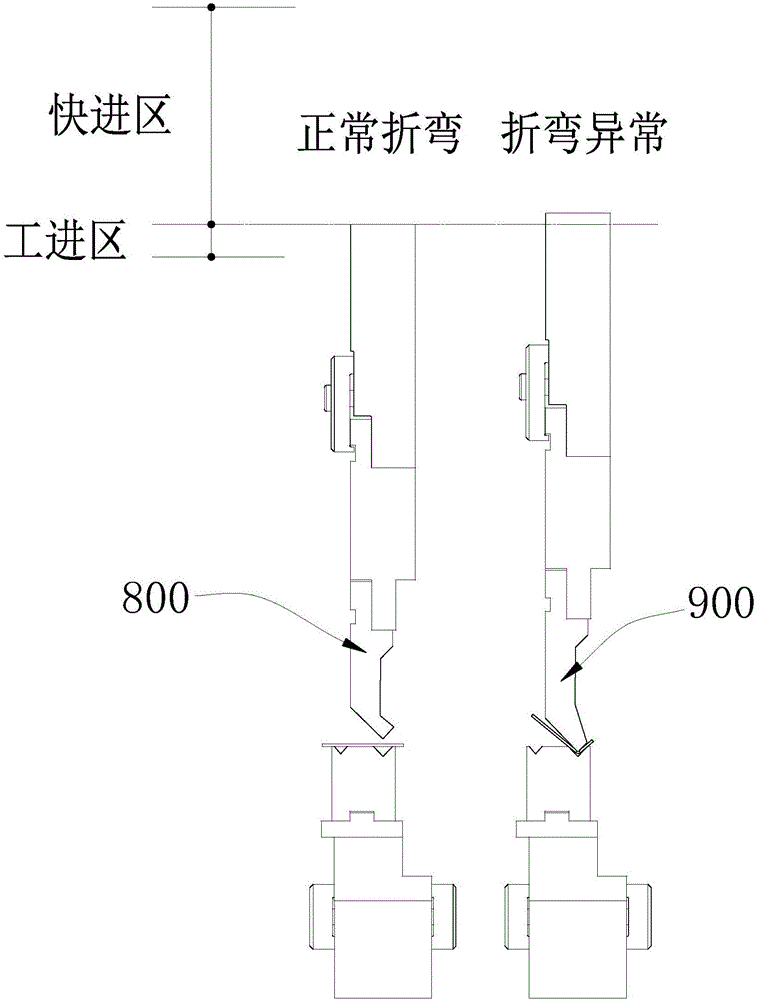

[0062] Such as Figure 4 As shown, A is the normal bending condition, B is the abnormal bending condition; the upper mold 101 is the normal upper mold, and the upper mold 201 is the wrong upper mold installed by mistake; the upper mold 201 is 20mm longer than the vertical effective dimension of the upper mold 101 , set the working distance as 15mm, that is, the upper mold 201, the workpiece 301 and the lower mold 401 have been completely crushed to death in the fast-forward area; Bending workpiece 301 requires a load value of 5 tons on the upper die; the determination condition for the abnormal load of the upper die is that the current feedback in the fast-forward zone is that the actual die load value exceeds the preset upper die load value by more than 5 tons, then the folded value in the second embodiment Bend abnormality judgment is a failure condition.

[0063] Then in the fast-forward area, the upper mold 201 presses down the workpiece 301 and gradually approaches the V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com