Riveting tool

A technology for riveting tooling and mounting holes, applied in the field of machining, can solve the problems of product quality impact, inconsistent rivet tightness, low assembly efficiency, etc., and achieve the effects of improving riveting reliability, uniform force, and improving connection and fastening quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

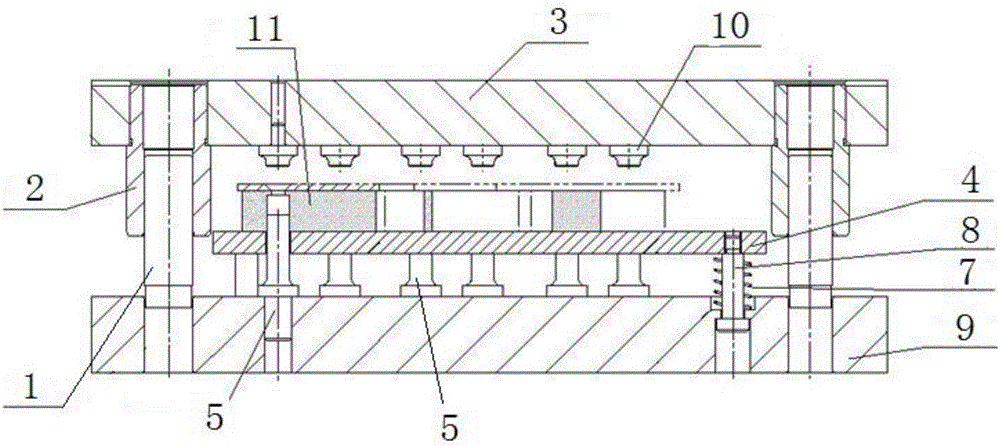

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0018] Such as figure 1 As shown, a riveting frock of the present invention includes an upper fixing plate 3 and a lower fixing plate 9, the upper fixing plate 3 and the lower fixing plate 9 are supported by a guide post 1, and the upper fixing plate 3 and the lower fixing plate 9 are supported by a guide post 1. Also be provided with support plate 4 between lower fixed plate 9, described support plate 4 is supported on the lower fixed plate 9 by some screws 8 evenly distributed, and described screw 8 can slide up and down in the installation hole of lower fixed plate 9; Several piers 10 are arranged on the lower plane of the upper fixing plate 3 .

[0019] A guide sleeve 2 is provided between the guide post 1 and the installation hole of the upper fixing plate 3 . The guide post 1 ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap