A method of laser forming ferrite products from glue surface of ferrite material

A ferrite material, ferrite technology, applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of increasing production links and production costs, particle foreign matter treatment unclean appearance, ferrite surface scratches and other problems, to achieve the effect of saving cleaning process, high yield rate, and easy to take products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

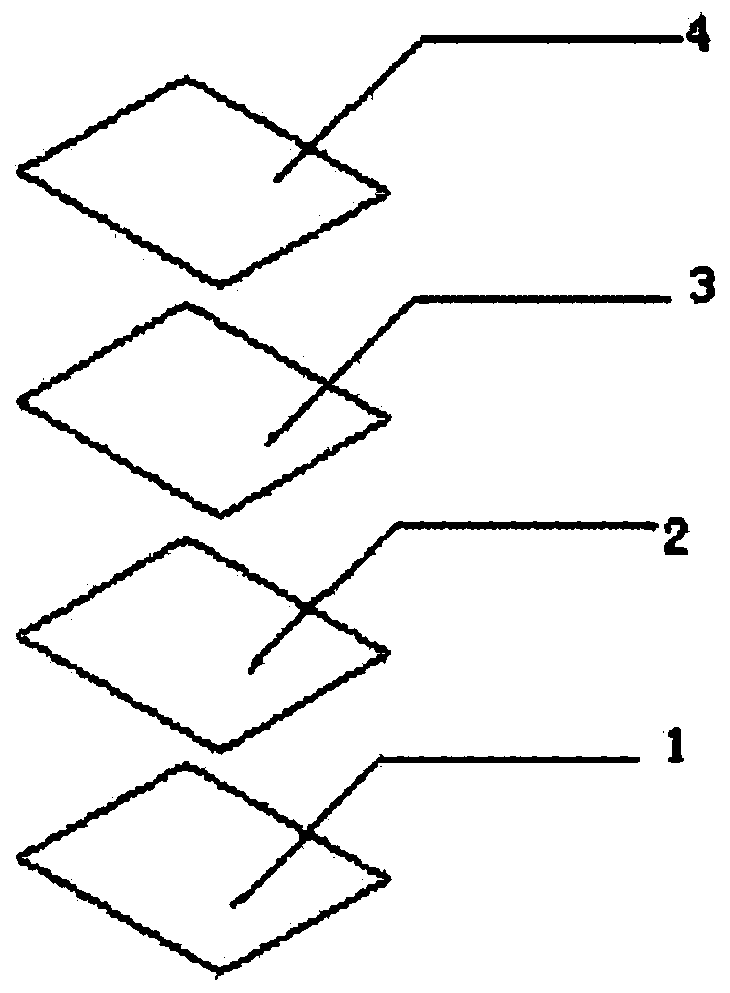

[0023] Raw ferrite materials such as figure 1 As shown, from top to bottom are the surface PET film 4 , the ferrite layer 3 , the adhesive layer 2 and the single-sided adhesive protective film 1 .

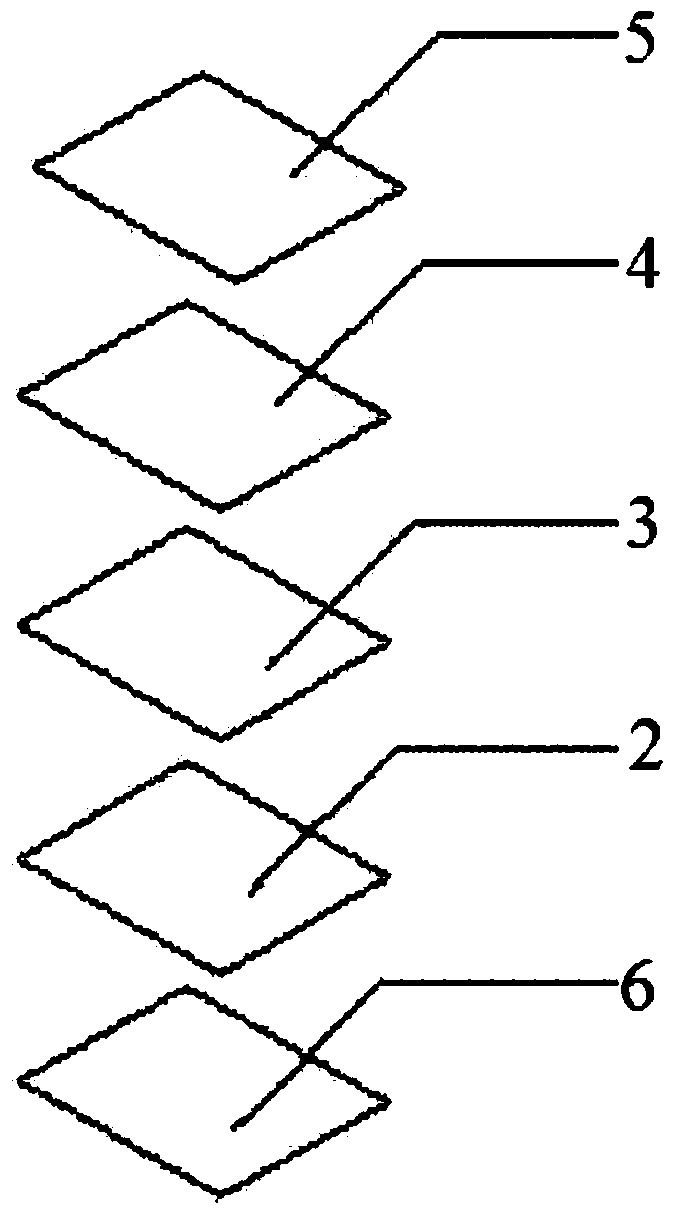

[0024] A method of laser forming ferrite products from ferrite material rubber surface, using laser cutting such as figure 1 The rubber side of the ferrite material shown is molded into a ferrite product. Before laser cutting, a layer of PET single-sided silicone protective film 5 is bonded on the surface PET film, and after the single-sided adhesive protective film 1 is peeled off, a layer of PET release protective film 6 is bonded on the adhesive layer 2, such as figure 2 As shown, the ferrite product is formed by laser cutting from one side of the PET release protective film 6 .

[0025] Wherein, the upper surface of the PET single-sided silica gel protective film 5 is a smooth surface, and the lower surface is a viscous surface. The viscosity of the lower surface of the PET...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com