A printing machine ink fountain roller rotation adjustment device

A technology of adjusting device and ink fountain roller, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of high maintenance cost and time can not achieve the desired effect, and achieve the effect of loosening the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

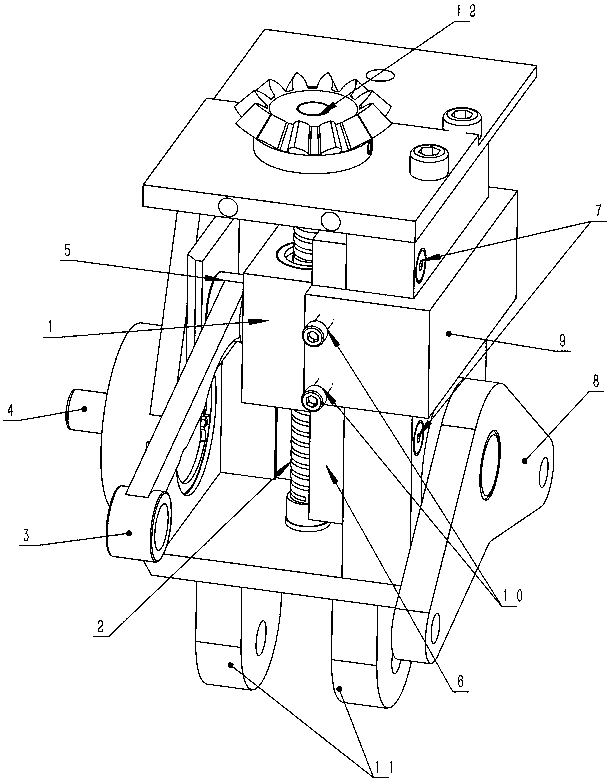

[0013] refer to figure 1 , a printing machine ink fountain rotation adjustment device, including a mounting seat, a guide block 1, a threaded rod 2, a connecting rod and a clamping device for clamping the guide block 1 and the threaded rod 2; the threaded rod 2 is arranged on the mounting seat ;The guide block 1 is provided with a threaded hole, the threaded rod 2 is inserted into the threaded hole, and one end of the threaded rod 2 is connected with the driving device; The other end is provided with a one-way bearing 3 for connecting the ink fountain roller. The driving device is a servo driver 12 .

[0014] The clamping device includes a pressure block 6, an adjusting bolt 10 and a U-shaped groove body 9 clamped on the mounting seat. The U-shaped groove body 9 is composed of a main board and two side plates fixed on the main board; the adjusting bolt 10 is arranged on On one of the side plates, the pressure block 6 is arranged between the adjusting bolt 10 and the guide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com