A semi-automatic optical fiber coloring machine based on conveying, cleaning, winding and positioning

A semi-automatic, coloring machine technology, applied in the direction of fiber mechanical structure, optics, light guide, etc., can solve the problems of easy entanglement, fiber dyeing and doping, reduced dyeing adhesion effect, etc., to achieve the effect of stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

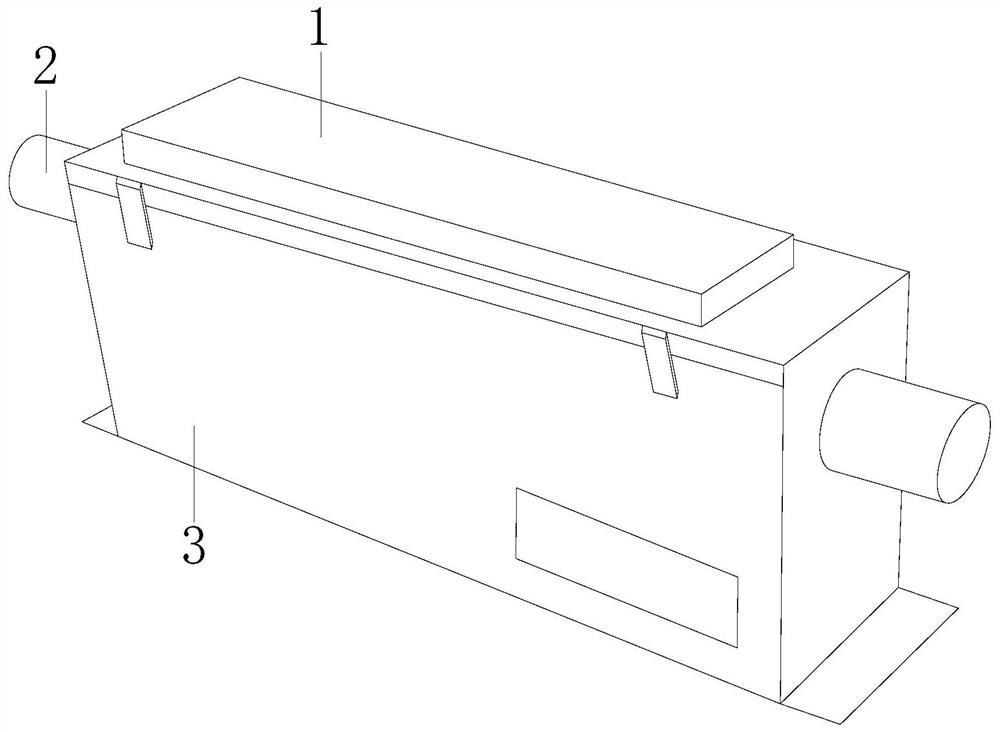

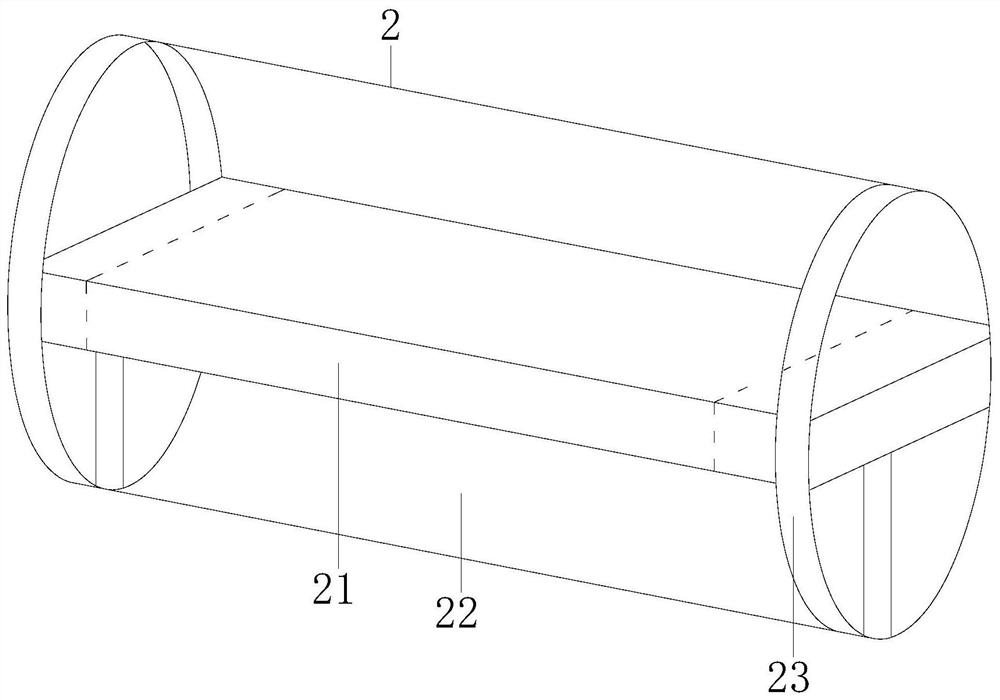

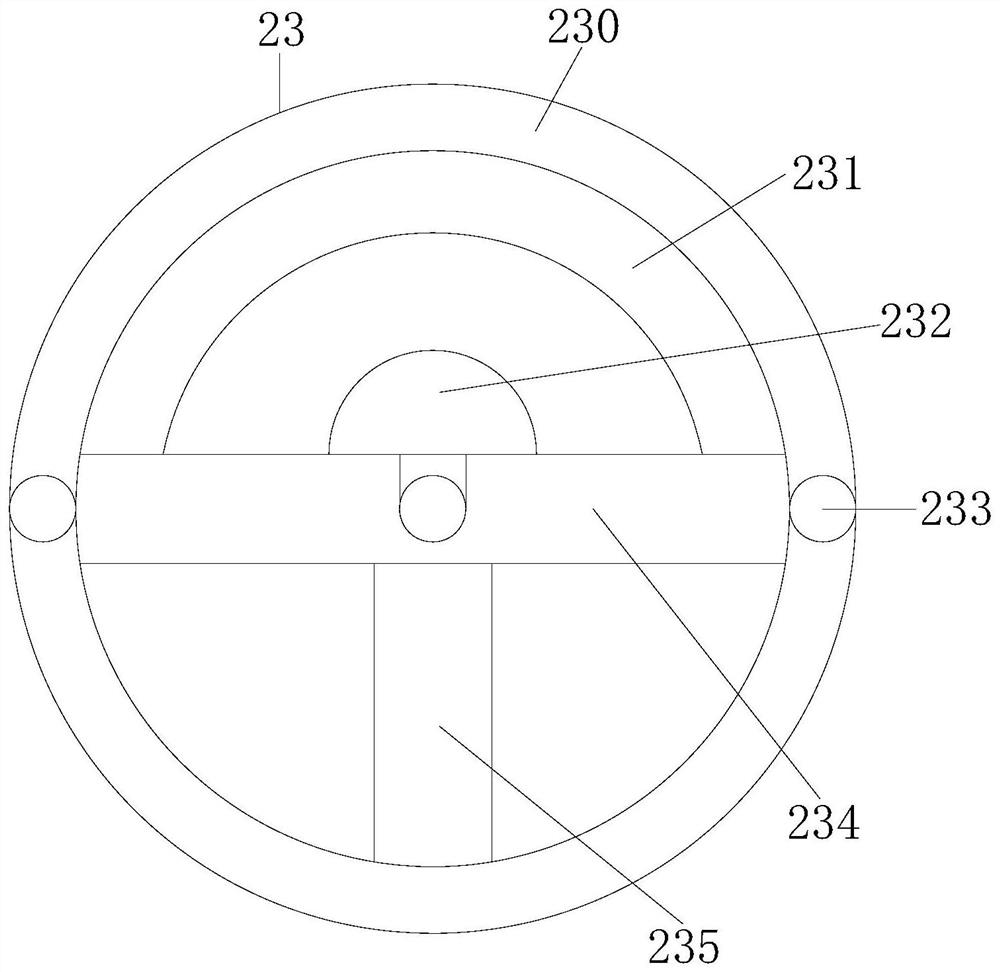

[0028] Example 1 see Figure 1-5 , the present invention provides a semi-automatic optical fiber coloring machine technical solution based on conveying, cleaning, winding and positioning: its structure includes a manual adjustment flap 1, an integrated pipe structure 2, and an installation box 3. The manual adjustment flap 1 can be opened manually It is used to adjust the optical fiber transmission and improve the smoothness of the optical fiber transmission. The manual adjustment flap 1 is installed and connected to the installation box 3, the integrated pipe structure 2 passes through the installation box 3, and the integrated pipe structure 2 is locked in the installation box 3. On the device box 3, the integrated pipe structure 2 is composed of a conveying rail 21, a pipe body 22, and a transmission end wheel 23. The conveying rail 21 is connected to the transmission end wheel 23, and the pipe body 22 is connected to the transmission end wheel 23 are assembled and connecte...

Embodiment 2

[0030] Example 2 see Figure 6-8 , the present invention provides a semi-automatic optical fiber coloring machine technical solution based on conveying, cleaning, winding and positioning: the two-position wire fixer 2103 in its structure includes a speed changer 400, a fiber adjustment structure 401, and an installation side plate 402. The speed changer 400 is axially connected to the fiber adjustment structure 401, the fiber adjustment structure 401 is locked with the installation side plate 402, and the speed of the speed changer 400 controls the turning angle of the cross bar 4011 to the shaft device 4013, so as to realize the angle adjustment of optical fiber transmission. The speed change machine 400 includes a fixed frame 4000, a transmission shaft wheel 4001, a transmission pulley 4002, and a transmission belt 4003. The transmission shaft wheel 4001 passes through the fixed frame 4000 and is connected to the transmission pulley 4002. The transmission pulley 4002 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com