Automobile rearview optical assembly

A technology for optical components and rearview mirror components, applied in the field of vehicles, can solve the problems of high cost, difficult to meet actual needs, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

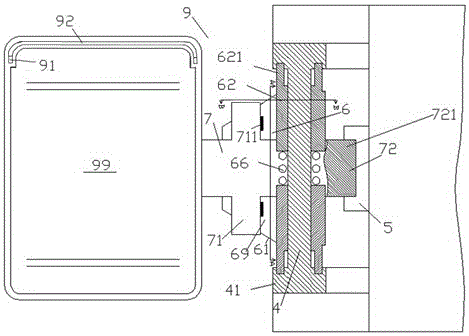

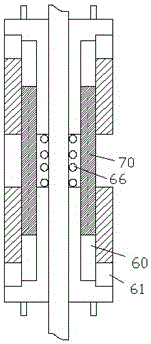

[0010] Combine below Figure 1-4 The present invention will be described in detail.

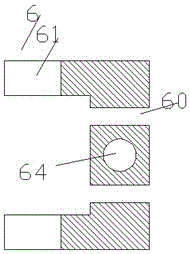

[0011] The automobile rearview optical assembly according to the embodiment includes a rearview mirror assembly 9 installed on the fixed shaft 4 of the vehicle. The fixed base 5 is fixedly connected with the vehicle body and includes an elastic material, which is slidably installed on the vehicle fixed shaft 4 and symmetrically arranged on the fixed base 5. The two rotation locking sliders 6 on the upper and lower sides of the two fixing plates 7, each of the rotation locking sliders 6 includes a sleeve part 62 sleeved on the vehicle fixing shaft 4 and a front and rear separately arranged. and fixed on the two inclined plates 69 at the front and rear sides of the sleeve part 62; wherein, the outer side of the sleeve part 62 is provided with a rotation preventing bayonet pin 621 for extending into the fixed position of the vehicle. In the bayonet hole in the rotation prevention chuck 41 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com