Device and method for measuring resistance and postures of ship module

A measuring device and ship model technology, which is applied in ship construction, ship design, ship parts, etc., can solve the problems that the heave rod of the rod displacement sensor is stuck with the bushing, hinders the free movement of the ship model, and cannot measure accurately. Achieve the effect of simple structure, small longitudinal sliding friction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047]The method of measuring with the ship model resistance and attitude measuring device is as follows:

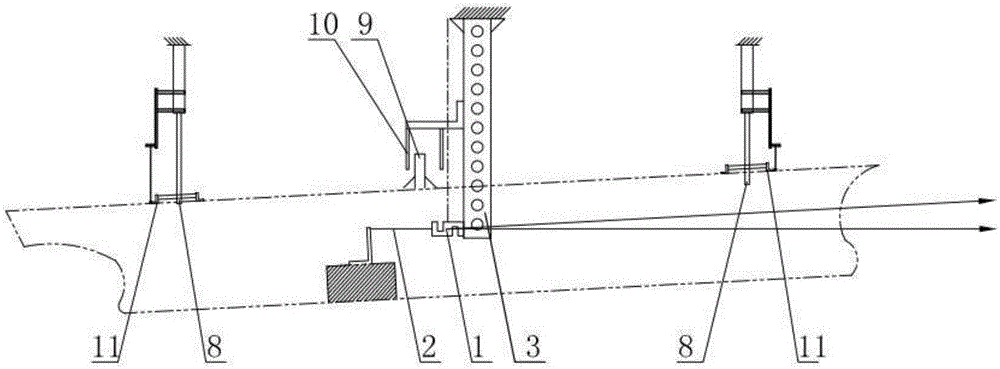

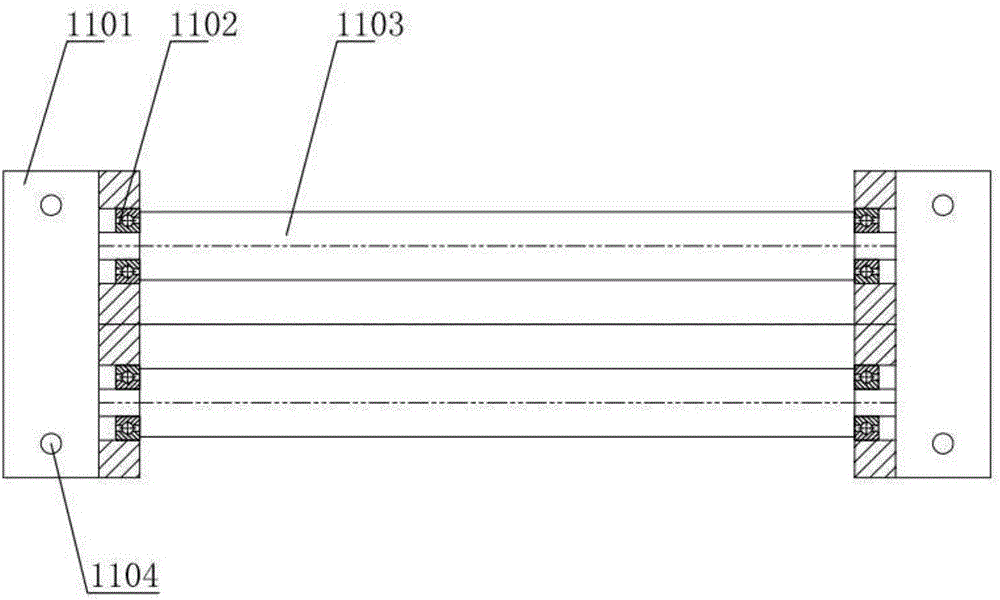

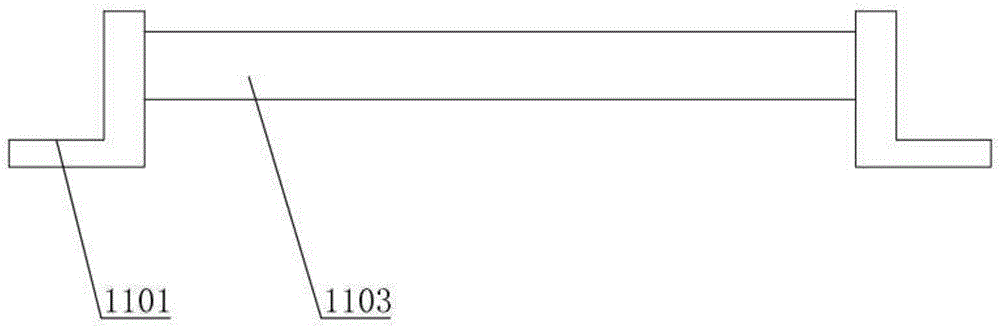

[0048] Such as Figure 6 , Figure 7 As shown, the ship model resistance measuring device composed of S-type resistance meter 1, towing support rod 3, pull-wire displacement measuring mechanism, and brake mechanism is placed on the special bridge measuring rail of the towing pool trailer; the navigation frame assembly and the brake plate Installed on the ship model; the acceleration of the trailer moves the resistance measuring device fixed on the rail of the measuring bridge, thereby driving the movement of the ship model connected with the resistance measuring device, and the clamping device 10 clamps the brake plate 9 during the acceleration of the trailer, so that The fluid force cannot be transmitted to the S-type resistance meter 1; after the trailer speed is stable, the clamping device 10 is released, so that the ship model resistance acts on the S-type resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com