Belt conveyor capable of being telescopically adjusted and lengthened

A belt conveyor, telescopic adjustment technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of general efficiency, waste, idle rails, etc., and achieve the effect of flexible use, flexible and convenient use, and scientific design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

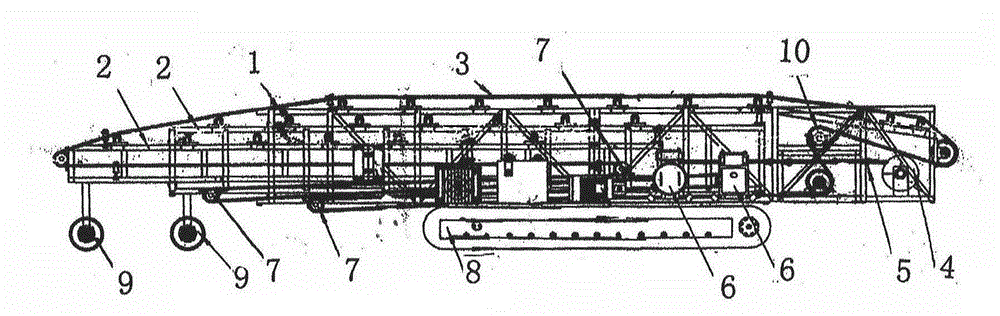

[0011] figure 1 As shown: the conveyor equipped with a telescopic adjustable extended conveyor belt is provided with a telescopic support 2 in the fixed support 1, an adjustable circulating conveyor belt 3 surrounds the overall support, and a telescopic adjustment hydraulic motor 4 is set under one end of the overall support. The telescopic adjustment motor 4 is provided with a traction rope 5 for adjusting telescopic adjustment, and is equipped with an electromagnetic starter 6, and a conveyor belt roller 7 is respectively set at the bending adjustment of the endless conveyor belt 3, and the entire body thus formed is fixed on the walking track 8 on the chassis. Supporting wheels 9 are set below the telescopic support 2 . Tension pulleys 10 are provided on the endless conveyor belt 3 .

[0012] When the present invention is implemented, various electrical components involved are selected from explosion-proof electrical components, that is, explosion-proof components, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com