Automatic folding and unfolding safety fence for lifting machine

An automatic retractable and safe guardrail technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of high cost of automatic opening and closing systems, cumbersome opening and closing operations of guardrails, unstable operation, etc. The effect of transportation and production efficiency, structure easy to obtain, stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

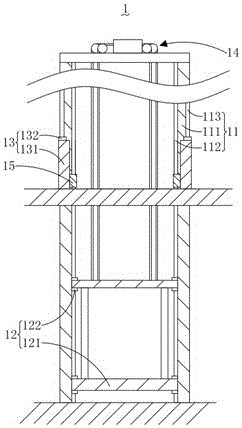

[0018] see figure 1 , is a cross-sectional view of an embodiment of the automatic retractable safety guardrail for an elevator provided by the present invention.

[0019] The automatic retractable safety guardrail 1 for the elevator includes four columns 11 , a box frame 12 , a guardrail 13 , a lifting mechanism 14 and a block 15 .

[0020] The column 11 includes a column body 111 , a frame guide rail 112 and a guardrail guide rail 113 . The frame guide rail 112 is arranged on the inner side of the column body 111 , and the guardrail guide rail 113 is arranged on the outer side of the column body 111 .

[0021] The box frame 12 includes a box frame body 121 and a box frame guide shoe 122 . The frame guide shoe 122 is disposed outside the frame body 121 .

[0022] The guardrail 13 includes a guardrail body 131 and a guardrail guide shoe 132 . The guardrail guide shoe 132 is disposed outside the guardrail body 131 .

[0023] The four column bodies 111 are arranged verticall...

Embodiment 2

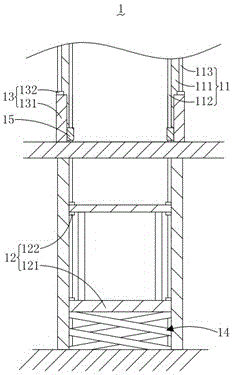

[0026] see figure 2 , is a cross-sectional view of another embodiment of the automatic retractable safety barrier for elevators provided by the present invention.

[0027] The automatically retractable safety guardrail 1 for the elevator in this embodiment is consistent with the structure in Embodiment 1 and will not be described in detail here.

[0028] The lifting mechanism 14 can also be a scissor-type lifting mechanism, which is arranged at the bottom of the column body 111 and connected to the bottom of the box body 121 .

[0029] During specific implementation, the lifting mechanism 14 is activated to push the frame body 121 to move upward. The top of the box frame body 121 is in contact with the stopper 15, driving the guardrail body 131 to move upwards, realizing the automatic opening of the guardrail. Similarly, when the frame body 121 moves down, the guardrail body 131 moves down synchronously and closes under the action of gravity.

[0030] Compared with the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com