Lifting type automatic guided vehicle (AGV)

A lifting mechanism and car body technology, applied in the field of lifting AGV, can solve the problems of inaccurate control, large turning radius, poor kinematic performance of the trolley, etc., and achieve the effect of flexible steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

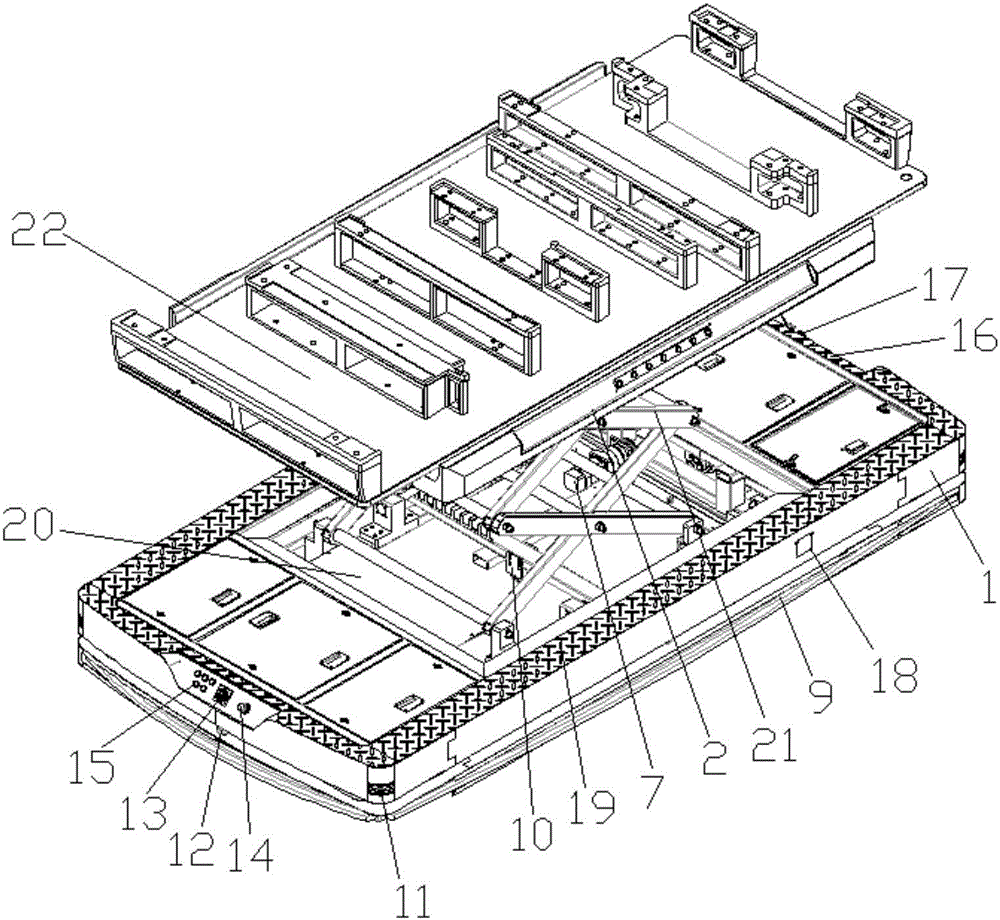

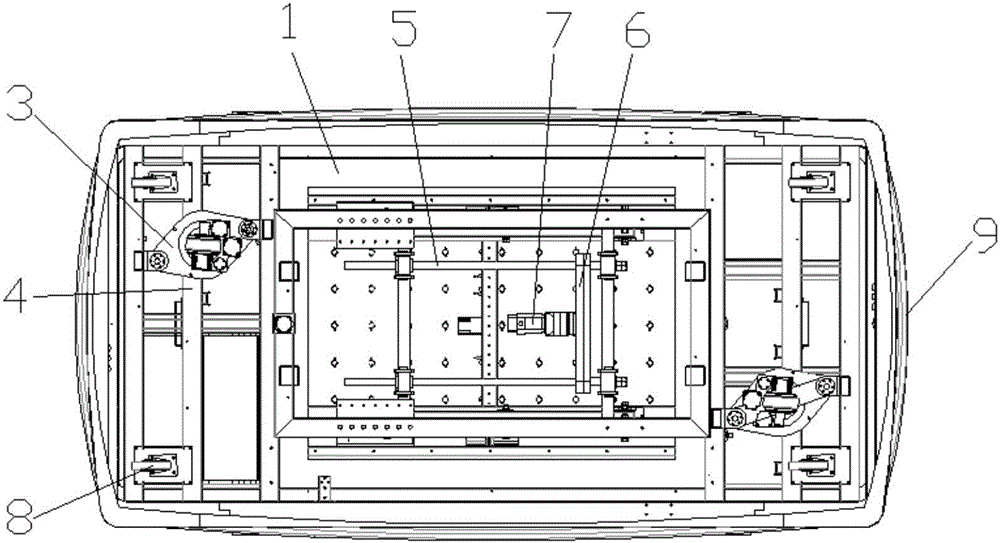

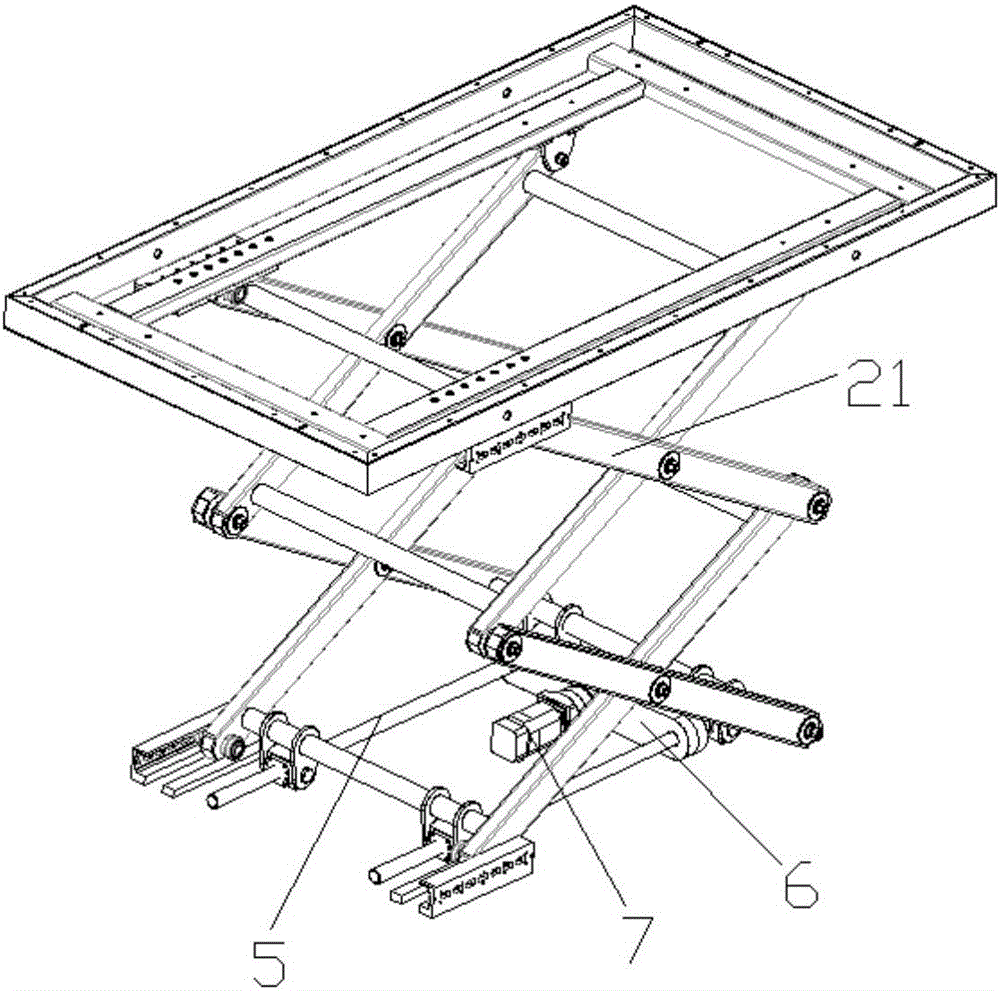

[0021] Such as Figure 1 to Figure 3 Shown, the preferred embodiment of the present invention, a kind of lifting type AGV, it comprises AGV car body 1 and is located at the lifting mechanism 2 on AGV car body 1, is respectively arranged on the four corners of the bottom of AGV car body 1 There is a universal caster 8 to provide support for the lift-type AGV, and the lift-type AGV can travel in any direction; the bottom of the AGV body 1 is provided with an RFID reader 10 for reading ground landmark information, and the AGV vehicle The front and rear of the bottom of the body 1 are respectively provided with a navigation magnetic strip for reading the ground magnetic strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com