Improved bio-pharmaceutical fermentation tank capable of eliminating fermentation medicine foam

A bio-pharmaceutical and fermenter technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biomass post-processing, etc., can solve problems such as waste of raw materials, reduction of production capacity, and inability to eliminate , to avoid aggravating the phenomenon of liquid escape, easy operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

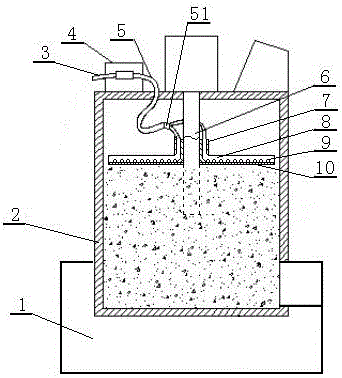

[0015] see figure 1 , the present invention provides a technical solution: an improved biopharmaceutical fermenter capable of eliminating fermentation bubbles, comprising a fermenter 2, a workbench 1 and a stirring shaft 6, the fermenter 2 is fixedly connected to the upper end of the workbench 1, the present invention The main features are: a micro air pump 4 is installed on the left side of the top of the fermentation tank 2, the input end of the micro air pump 4 is sealed and connected with an air extraction pipe 5, and the output end of the micro air pump 4 is sealed and connected with an exhaust pipe 3.

[0016] The outside of the stirring shaft 6 is sleeved with a ring 7, and the lower sides of the ring 7 are respectively provided with air extraction plates 8, and the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com