Connection design and construction method for newly-built subway entrance and exit and existing fabricated street underpass

A construction method and street-crossing technology, applied in roads, roads, buildings, etc., to achieve the effect of saving engineering investment, good promotion significance, and saving underground space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

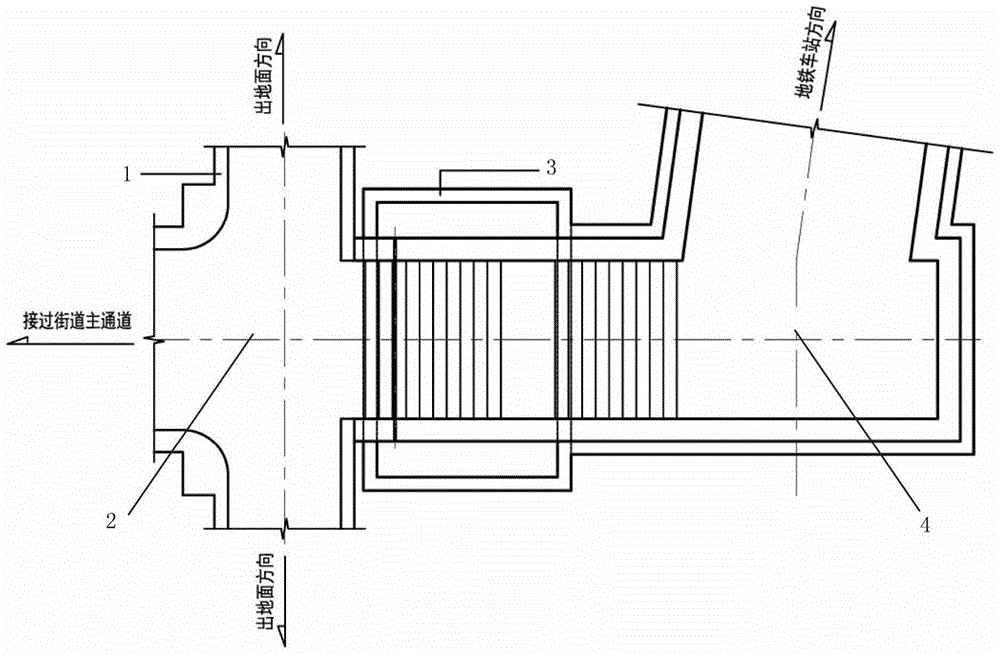

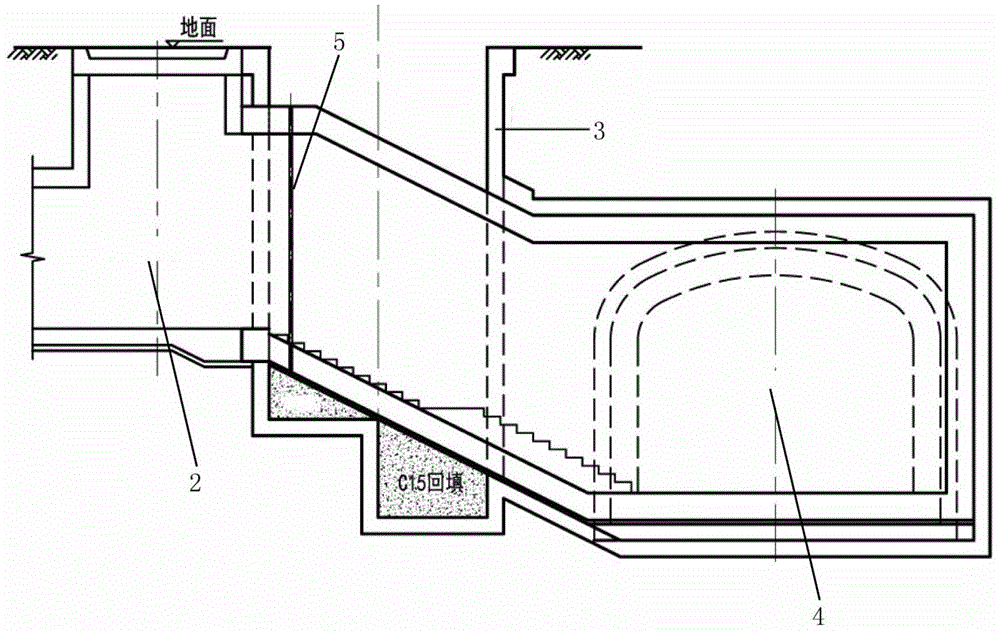

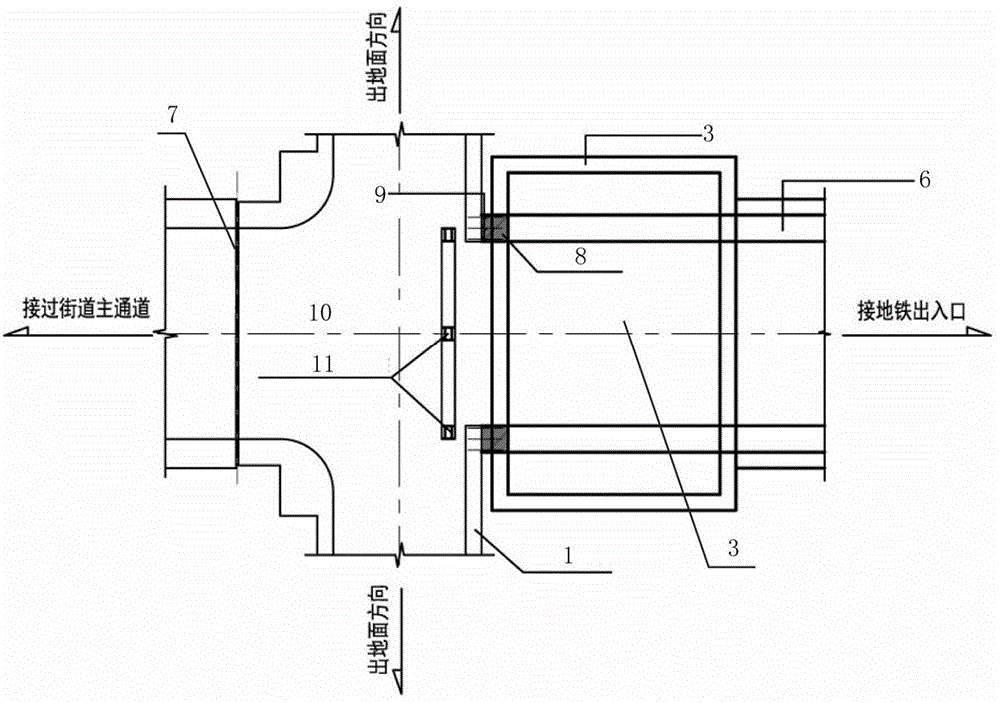

[0028] Such as Figure 1-5 As shown, a new subway entrance and exit and the existing prefabricated cross-street connection design and construction method are carried out according to the following steps:

[0029] (1) Before the excavation of the temporary shaft 3, perform grouting treatment within 0.5m around the shaft, and backfill and grout the area affected by the construction under the floor of the existing crossing street 2, and strictly control the grouting pressure not greater than 0.3MPa;

[0030] (2) In the existing crossing street 2, the Shuangpingong 25a door frame beam protection system is used to protect the prefabricated foyer crossing the street to ensure the safety of the existing crossing street 2;

[0031] (3) Plant bars on the outer wall of the existing crossing street 2 structure, and pour the connecting ring frame bottom plate, that is, first form a reinforced ring beam support system, and then remove the existing structure;

[0032] (4) Use rhinestones t...

Embodiment 2

[0035] Such as Figure 1-5 As shown, a new subway entrance and exit and the existing prefabricated cross-street connection design and construction method are carried out according to the following steps:

[0036] (1) Before the excavation of the temporary shaft 3, perform grouting treatment within 2m around the shaft, and backfill and grout the area affected by the construction under the floor of the existing crossing street 2, and strictly control the grouting pressure not greater than 0.3MPa;

[0037] (2) In the existing crossing street 2, the Shuangpingong 25a door frame beam protection system is used to protect the prefabricated foyer crossing the street to ensure the safety of the existing crossing street 2;

[0038] (3) Plant bars on the outer wall of the existing crossing street 2 structure, and pour the connecting ring frame bottom plate, that is, first form a reinforced ring beam support system, and then remove the existing structure;

[0039] (4) Use rhinestones to ...

Embodiment 3

[0042] Such as Figure 1-5 As shown, a new subway entrance and exit and the existing prefabricated cross-street connection design and construction method are carried out according to the following steps:

[0043] (1) Before the excavation of the temporary shaft 3, perform grouting treatment within 5m around the shaft, and backfill and grout the area affected by the construction under the floor of the existing crossing street 2, and strictly control the grouting pressure not greater than 0.3MPa;

[0044] (2) In the existing crossing street 2, the Shuangpingong 25a door frame beam protection system is used to protect the prefabricated foyer crossing the street to ensure the safety of the existing crossing street 2;

[0045] (3) Plant bars on the outer wall of the existing crossing street 2 structure, and pour the connecting ring frame bottom plate, that is, first form a reinforced ring beam support system, and then remove the existing structure;

[0046] (4) Use rhinestones to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com